Fresh Noni Enzyme Powder for Solid Beverage Powder Making Machine for Sale

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Gas

- Process:Concentration and Dry

- Automatic Grade:Automatic

- Application:Powder

- Customized:Customized

=== Base Info ===

- Model NO.:100L-5000L

- Transport Package:Wooden Cases

- Specification:10-6000L

- Trademark:Genyond

- Origin:China

- HS Code:8419399090

- Production Capacity:100set,Year

=== Description ===

Basic Info.

Model NO. 100L-5000L Transport Package Wooden Cases Specification 10-6000L Trademark Genyond Origin China HS Code 8419399090 Production Capacity 100set/YearProduct Description

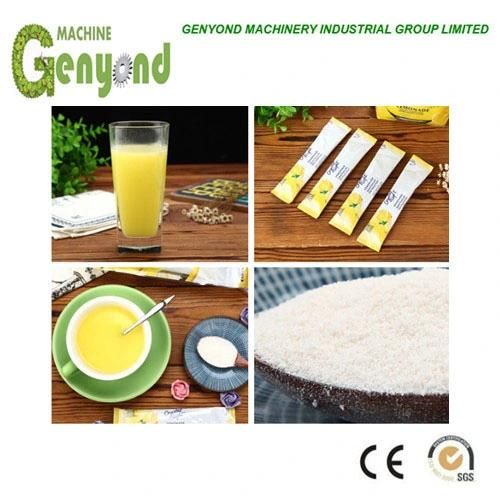

Solid drinks refer to the products made of solid materials such as powder, granule or block by processing food raw materials and food additives, such as juice powder, bean powder, tea powder, coffee powder, fruity solid drinks, solid soda (effervescent tablets) and ginger juice powder.According to the form of solid beverage, it can be divided into powder type, particle type, tablet type, block type and other types. In addition, solid drinks can also be divided into two types, fizzy and non-fizzy, according to whether they are foamed after being dissolved in water.

Including flavor, pigment, acidity regulator, sweetener, etc.

2. Solid beverage technology process

There are many kinds of solid drinks, such as tea, coffee, cereals, health care and so on. In the early stage, we can refer to the production process of beverage, which often includes mixing, filtration, heating and other processes. A big difference between the process of liquid beverage and solid beverage is that solid beverage has drying process. So let's focus on the drying process.

Freeze drying, fluidized bed granulation and spray drying are three main processing methods in solid beverage production. Freeze-drying is a kind of advanced drying technology, which can preserve the nutrition and flavor of the materials well. Fluidized bed granulation is suitable for dry materials with low or no juice. Spray drying technology is suitable for drying liquid materials with high content of fruit juice. Because the temperature of the materials is low and the time is short, the nutrition and flavor of the materials can be well preserved. Other processing methods of solid beverage include spray freeze drying and vacuum drying.

1) Lyophilization

Freeze-drying method is to freeze the water in the material into solid ice, in the vacuum condition, make the water sublimate directly into water vapor escape, so as to remove water from the material. Its characteristics are that the nutrients and volatile components are well preserved, but the processing cost is very high, so there are few solid drinks produced by freeze-drying method, and only a few products with higher added value, such as instant tea powder and coffee powder, are applied.

Lyophilize Machine Picture:

2) Granulation

The granulation technologies include wet granulation, dry granulation, quick mixing granulation and fluidized bed granulation. Fluidized bed granulation, also known as boiling granulation, is a new granulation technology, which is completed in three steps of conventional wet granulation, including mixing, granulation and drying, in an airtight container at one time. In 1959, Dr. Worsted of Wisconsin first proposed fluidized bed granulation technology. Subsequently, this technology developed rapidly and was widely used in pharmaceutical, food and chemical industries. Fluidized bed granulator was introduced from abroad in 1980s and has been widely used in China in recent years.

Particle growth in fluidized bed granulation generally has three mechanisms - agglomeration, coating and cumulative granulation. In the process of fluidized bed granulation, these three actions often make the granule grow together. The purpose of food industry granulation, mainly to solve the instant, and make good appearance, improve liquidity, easy to pack, so as to improve the value of goods. At present, the domestic production of instant fruit and vegetable solid drinks, the general use of mixing, granulation, drying method, the use of swing granulator, but the direct use of swing granulator processing of solid drinks is the main disadvantage of high content of excipients.

Granulation Machine Picture:

3) Spray Drying

Spray drying is a process in which the material liquid is dispersed into fine fog drops by atomizer and the solvent is rapidly evaporated in the hot drying medium to form dry powder. The material liquid can be in the form of solution, suspension, emulsion and other liquids that can be transported by pump. The dried product can be in the form of powder, particle or agglomerated particles.

In addition to milk powder, instant bean powder and tomato powder, there are also reports on lychee powder, lotus root powder, banana powder and strawberry powder. The powder processed by spray drying has small loss of nutrition and good color. But the powder after spray drying, generally smaller grain size, poor impulse, need to be granulated before direct impulse. Instant milk powder is the most typical solid drink that can be rapidly dissolved into hot and cold water by agglomeration granulation after spray drying, and its research is also the most popular.

Spray Dryer Picture:

Welcome to contact us:

Ms. Jelly Tel/8618516198359

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23