1500W Metal Fiber Laser Cutting Machine 2000W / CNC 1000W Fiber Laser Machine Cut 1kw for Metal Stainless

LTLD ESD CO., LTD. / 2022-06-23

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

- Laser Classification:Free Electron Laser

=== Base Info ===

- Model NO.:Ta-Fls3015-1000W

- Laser Technology:Laser Fusion Cutting

- Model No.:Ta-Fls3015-1000W

- Working Area:3000*1500mm

- Power Supply:380V,50Hz,60Hz

- Processing Technology:Annealing and Abrasive Blasting

- Laser Source:Ipg,Raycus

- Control System:Cypcut

- Color:Red and Black

- Certification:FDA,Ce

- Transport Package:Wooden Case

- Specification:1000W

- Trademark:TA

- Origin:China

- HS Code:8456110090

- Production Capacity:200 Sets,Year

=== Description ===

BOCHU, China

2.Technical Data

Power

Gas

Cutting Gas

Working

Temperature requirements

5-40 Degree

Foundation requirement

There should be no vibration source nearby

on site or nearby, the user is

required to dig an anti-vibration trench around the foundation

5.Fiber laser System

5.1.1 Fiber Laser Generator

Raycus 1000W

No lens built inside laser generator to avoid maintenance

Beam delivery system consists of fibers

Compact-design, easy for integration

Start-up time not needed

Excellent cutting capability

Good beam quality and high power density

Fiber Laser Conversation Efficiency is more than 30%, compared with YAG or CO2 machine, it significantly saves power consumption when working ,saving running costs and to achieve the highest production efficiency.

Fiber laser adopting Semiconductor Modular and Redundancy Design ,there is no optical lens in resonant cavity like YAG, it doesn't need any start time, featuring free adjustment, free maintenance, high stability, reducing parts cost and maintenance time, which is incomparable by other traditional cutting machinery.

SS<=6MM

SS<=8MM

10 cutting Speed:

1000W Fiber Laser Cutting Machine Carbon Steel

1500W Fiber Laser Cutting Machine Carbon Steel

11. Advantages of fiber laser cutting machine:

(1)Adopted to import fiber laser generator, with long using life up to 100000 hours and high cutting speed up to 80m/min;

(2)Japan YASKAWA Servo motor with double ball screw driving system, can make sure the cutting high precision especially comparing with the single driver system.

(3)Swiss raytools laser head with auto focusing height follower, which can ensure the constant same

distance between the head and cutting material

(4)Cypcut cnc cutting System, which has the special funnel design to make collecting more easy.

12. Package and Delivery:

(1)We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickness plastic bag for waterproof.

(2)Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to all of the world. So please don't worry, you will receive the machine in good condition.

(3)Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. Any problem,you can ask, we will response within 24 hours for you.

13. Guarantee and Service:

Warranty

1. All of our machine will be full-checked by our quality control department before the shipment. We make sure that customers will be get good products from us, and all of our machine with two years quality guarantee period.

2. Our engineer will make a door-to-door instruction training service.Ps:Our technician can go to client's country offer training according to client's demand and schedule(client is supposed to afford to the tickets and visa fee ,accommodation and food)

3. 24 hours online support ,Service response time: within 2 hours .We will offer plenty of online supports, by email, telephone, skype, whatsapp, wechat and so on.

Quality control

1.Skilled and strict Quality inspection Team is available during the material purchasing

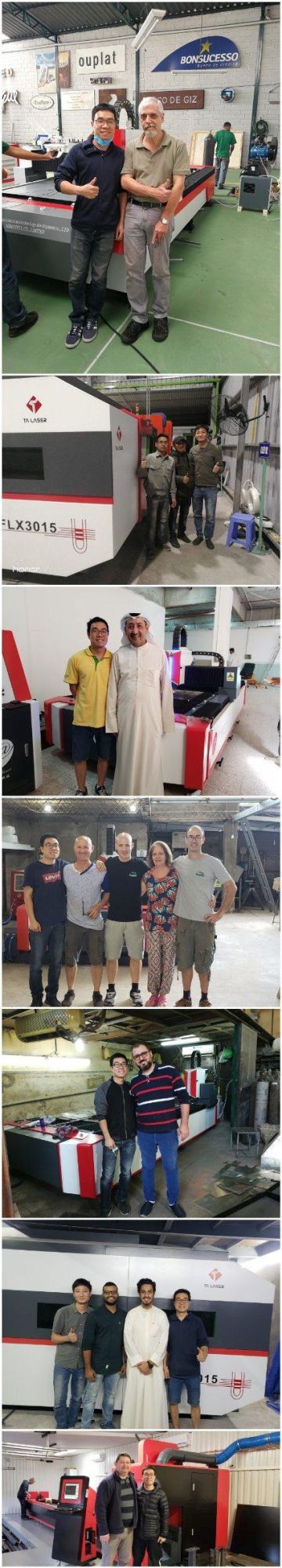

and production procedure.Here is some of our partner

2.All finished machine we delivery are 100%strictly tested by our QC department and

engineering department.

OEM Service

1.Customized and OEM orders are welcome due to our aboundant experiences.

All the OEM service are free,customer only need to provide us with your logo

drawing,function requirements,colors etc.

2. No MOQ required

Privacy

None of your personally identifiable information will be disclosed or shared

with any third parties.

Payment

1.30% deposit in advance, 70% balance before shipment

2.Irrevocable L/C at sight

14. Installation and feedback :

Why TA LASER can be your partner ?

1. TA laser located in Wuhan, China, where is famous for laser industry. Most laser companies are here in Wuhan Optical Valley, so we have superior geography position. And we have already established long term cooperation with stable clients and suppliers after working in laser industry wholeheartedly in those years.

2. Team Work: The TA members come together not only because of the common interest but for the common dream. We love our job and try to get recognized from it, so all of our staffs working with passion. And we are not only colleagues but also family. TA laser want to build a long relationship with our customer not just one-time transaction. We all enjoy the process to solve the problems which our customers faced. Because we know this is the best way to eliminate barriers and improve customer satisfaction. We believed that once we do our job wholeheartedly, the customers will see it and glad to work with us.

3. Our Sales-Network:

TA laser are dedicated to bringing best laser products to the world-wide customers. We are establishing our sales and distributors network all over the world. Now we already had close contact with our clients from all the world like Thailand, Indonesia, Malaysia, Singapore, India, Kuwait, U.S, Mexico, Brazil, Argentina.... Welcome to work with TA laser!

FAQ:

Q1: I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using machine, then let's give you perfect solutions and suggestions.

1)Your materials.

2)The size of material: ___mm*___mm

3)You want to engrave or cut? If cut, what's the cutting thickness?

Q2: How long is the delivery time?

For standard machines, it would be 15-25 workdays; For non-standard machines and customized machines according to client's specific requirements, it would be 25 to 40 workdays.

Q3: Are you a Factory or Trading company?

We're a professional manufacturer with export license.

Warmly welcome at any time to visit!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23