5L 10L 20L HDPE/LDPE/PP Bottle Extrusion Blow Moulding Machine

Jiangsu Yaofeng Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

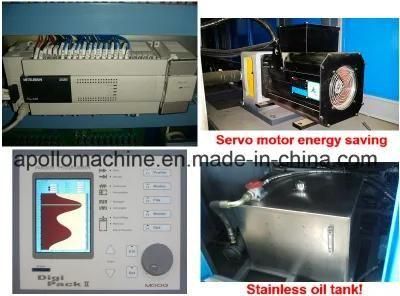

Model NO. ABLB90II Application Bottles,Jars,Jerry Cans,Gallons,Containers Max Bottles This Machine Can Make 20L Station Single/Double Parison Control System Moog 100 Points PLC Mitsubishi Electrics Schneider Hydraulic Yuken Invertor Delta/ABB Motor Siemens Guarantee 15 Month Transport Package Film Packing Specification ABLB90II Trademark APOLLO Origin Zhangjiagang City, Jiangsu Province, China HS Code 8477301000 Production Capacity 180~200PCS/HProduct Description

ABLB90 automatic blow molding machine machine was specially designed for making plastic water tanks, plastic cans, lubricant oil bottles, plastic drums, plastic toys and other plastic containers not over 20L.

The features of this machine:

(1)It is suitable for producing PE, HDPE, PP, PVC so on, plastic containers and bottles in all shapes are available, the max. Product volume is up to 20L.

(2)Double station single die head design, very easy to operate and maintenance.

(3)Most components of the blow moulding machine are from famous world brand.

(4)Fully automatic process with low power consumption, high efficiency, quick and safe operation, easy for maintenance.

(5)Multiple screw available for double layer or tranparent liquid lever line.

(6)Auto deflashing device available, can remove the extra parts of bottles.

(7)Auto lubricant system controlled by PLC.

| Max. Product volume | 20 liters |

| Output capacity | 200pc/h |

| Screw diameter | 90mm |

| Screw L/D ratio | 25 L/D |

| Screw drive power | 37KW |

| Screw heating capacity | 18 KW |

| No.of heating zone | 4 zones |

| Output of HDPE | 130KG/H |

| Oil pump drive power | 11KW |

| Clamping force | 110KN |

| Max.size of mold | 530X550mm |

| Mold stroke | 180-680mm |

| Max.die diameter | 200mm |

| Blowing pressure | 0.8 mpa |

| Air Volume | 1 M³/MIN |

| Cooling water pressure | 0.3mpa |

| Water consumption | 90 L/MIN |

| Size of Machine | 4.2x3x3.2m |

| Weight of machine | 11ton |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23