Stainless Steel Sanitary Food Grade Round Type Tank Manway (JN-ML1004)

Defi Plastics Industry Limited / 2022-07-04

- Process:Mild Processing

- Power Source:Electric

- Certification:ISO9001

- Automatic Grade:Semi-Automatic

- Application:Milk, Yogurt, Milk Powder, Cheese

- Customized:Customized

=== Base Info ===

- Model NO.:JN-ML1004

- Body Material:SS304, SS316L

- Sealing Material:Silicone, EPDM, Viton, PTFE, or NBR

- Qualified Certificate for Seal:FDA

- MOQ:1PCS

- Raw Material:Forging or Casting

- Processing Machine:LG Mazak CNC Machine

- Standard:SMS, ISO, as, BS, Bpe, Rjt, 3A, Idf

- Acting Mode:Manual or Pneumatic or Electrical

- Inner Surface Finish:Ra 0.5

- External Surface Finish:Ra0.8

- Connection:Weld, Clamp, Male, Female, Union, Flange

- Transport Package:Wooden Case

- Specification:DN200-DN600

- Trademark:JONENG

- Origin:Wenzhou, China

- HS Code:73072900

- Production Capacity:10000PCS,Month

=== Description ===

29 nos of LG Mazak CNC Machines

4 nos of local CNC machines

2 nos of automatic CNC center

12 nos of plain lathe

For pipe fittings

4 nos of press

3 nos of cutting machine

3 nos of chamfering machine

We also have the following quipments

4 nos of polishing machine

12 nos of grinding machine

3 nos of laser marking machine

3 nos of pressure testing machine

1 nos of temperature testing machine

3 nos of spectro instrument

1 nos of surface roughness device

OUR STOCK

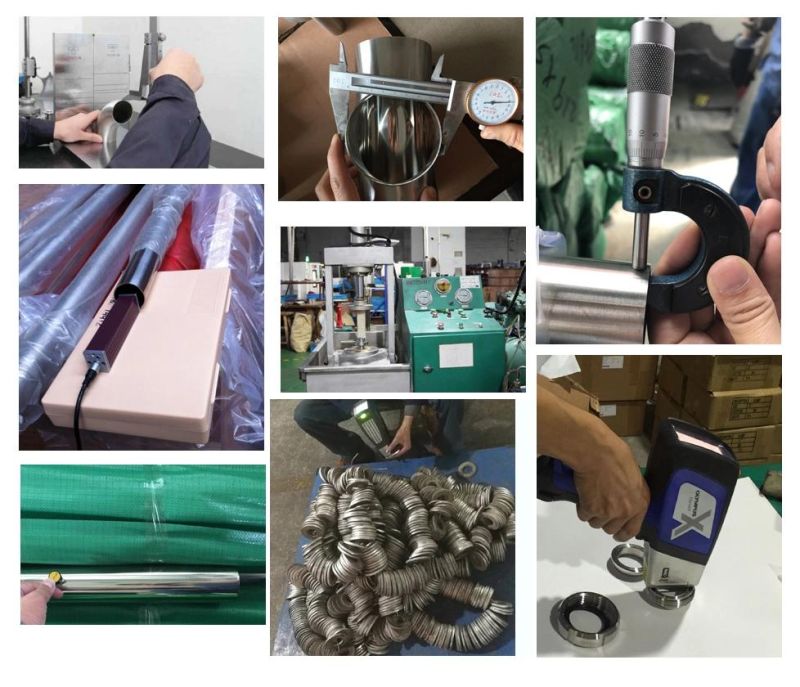

OUR INSPECTIONHOW DO WE MAKE THE QUALITY CONTROL

Raw Materials

2. Sand hole inspection after raw materials are machining before polishing.

3. Carbon component report can be provided if needed

4. Mechanics test report can be provided if needed

For finished materials

7. After we get the finished products, we check for surface roughness, thickness equality, roundness, size measurement and sand holes again.

8. For all finished products, the checking quantity is not less than 10% of total quantity.

9. Before shipment, we check for the quantity of each product in order to find out any missing quantity or wrong product.

OUR PACKAGING

OUR PACKAGING

OUR EXHIBITION

FAQ:

1. Are you a trading company or factory?

We are a manufacturer factory and we also have our own exporting license.

2. Do you have certificate ?

Yes, ISO, FDA, LFGB, CE, PED certificate . We also have some patents in design.

3. How do you control the quality?

In quality control ,the most important is to avoid material mixing .

In our factory , 3 spectro PMI machines are used in raw material warehouse, production plant, dispatch plant.

Pressure inspecting machine, PMI machines, RA roughness spector, hardness testing machine..... all machines help in inspection.

2 staff inspect during production in different sections

5 staff inspect the finished productions to avoid shortage, poor quality, mixing chemical....

4. If there is any quality problem, how do you solve it?

We are very proud that we never make one customer leave us. We are not 100% perfect, there is some quality problem.

Normally replacement, or compensation, or resend goods to customers as per the condition. To be discussed as per condition.

5. How long is your delivery time?

For normal products in 7-10 days; for bulk order, in 15-25 days. It depends.

6. Warranty time?

3 years warranty for all of our stainless steel products. Gaskets or the easy broken parts are not included due to the different application for customers.

7. Why trust in us ?

14 years in this industry . It makes us professional .Good credit in this market.

All of our machines are the assurance of our responsibility.

8. Free sample ?

Free samples can be provided for first cooperation under sincere cooperation.

9. What is the MOQ?

1pcs MOQ is welcome for starting cooperatoon

10.Material certificate ?

Material certificaite, mill certificate, pressure testing certificate, roughness certificate, measure certificate, RT certificate,... can be available, please declare when inquiry us.

11. More questions are appreciated.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23