Plastic Pipe Machine - HDPE/PPR Pipe Extrusion Line

HUAIAN ZHONGYUAN FLUID TECHNOLOGY CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. MT20-315 Condition New High Speed 30m/Min Inverter ABB Schneider Contact Schneider Haul off Servo Motor Transport Package Wood Specification ce Trademark Middle tech industry Origin Zhangjiagang City HS Code 84772090 Production Capacity 30 Unit/YearProduct Description

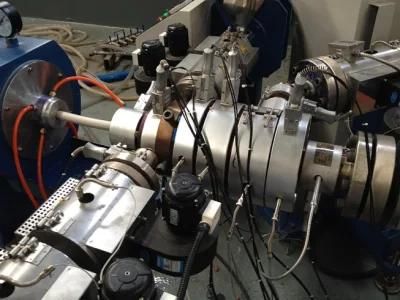

Production introduce:HDPE/PPR/LDPE plastic Pipe machine extrusion and production line

PART 1 INTRODUCTION:

HDPE/PPR/LDPE series plastic pipe extrusion line is mainly used in the area of agricultural water supply, architectural water supply, gas supply and transportation, telecommunication cables etc. This line has the advantages of easy operation, high automatic degree, stable and reliable production, well received by customers.

PART 2 FEATURES OF THIS LINE

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul off machine → cutting machine → stacker

1) Single screw extruder

adopts long L/D, high efficiency screw, high extrusion capacity, uniformed plasticization. Extruder and haul off machine motors adopt imported AC/DC inverter as speed regulators.

2) Extrusion die head

is spiral type, good calibrating makes good quality pipe production.

Inner heating system, high efficient, easy extrusion. Bronze calibrators can make the pipes fast calibrated and cooled.

3) Vacuum calibrating tank and water spraying cooling tank

adopts advanced water circulation, high pressure cooling system, installed with vacuum degree adjusting device and automatic water temperature and water level controlling system.

4) Haul off machine

adopts caterpillar type, which includes two-claw types, three-claw types, four-claw types, six-claw types, eight -claw types, ten-claw types, twelve-claw types etc, suitable for different sizes of pipes.

5) Non-scraped cutting, saw cutting or planetary cutting

can be applied, accurate cutting, reliable property, high efficiency. Meter-counting device is also installed.

PART 4 ADVANTAGES OF THE PIPES PRODUCED BY THIS LINE

Pipe produced by this line has excellent hardness and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress cracking resistance and creep resistance, hot-melt connectivity, and other advantages, it is the first choice of city gas and water transmission pipe line.

| Model/data | Pipe diameter(mm) | Co-extruder model | Speed (m/min) | Max capacity (kg/h) | Installed power(kw) | Dimension(m) | weight(t) |

| LSG65/30 | 16-63 | LSJ25/25 | 1.2-15 | 100 | 75 | 32*3.0*2.2 | 9.5 |

| LSG65/33 | 20-110 | LSJ25/25 | 0.3-12 | 150-180 | 98 | 36*3.1*2.2 | 10.5 |

| LSG75/33 | 63-160 | LSJ25/25 | 0.5-5 | 220 | 120 | 40*3.2*2.4 | 12.5 |

| LSG90/33 | 160-400 | LSJ30/25 | 0.5-2 | 450 | 320 | 52*3.3*2.6 | 27.5 |

| LSG120/33 | 355-630 | LSJ30/25 | 0.1-1 | 800 | 510 | 60*3.5*2.8 | 41 |

| LSG150/33 | 400--800 | LSJ45/25 | 0.1-0.5 | 1000 | 630 | 68*3.6*3.0 | 62.1 |

| LSG150/33 | 800-1200 | LSJ45/25 | 0.07-0.8 | 1200 | 790 | 72*3.8*3.0 | 81.3 |

| LSG150/33 | 1000-1600 | LSJ45/25 | 0.03-0.4 | 1400 | 880 | 75*4.0*3.2 | 92.5 |

If you do need any support, please don't hesitate to contact me on 0086-13962227556.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23