Plastic PP PE LDPE HDPE BOPP PBT Woven Bags Bottle Flakes Recycling Water Ring Single ...

Taizhou Legenton Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

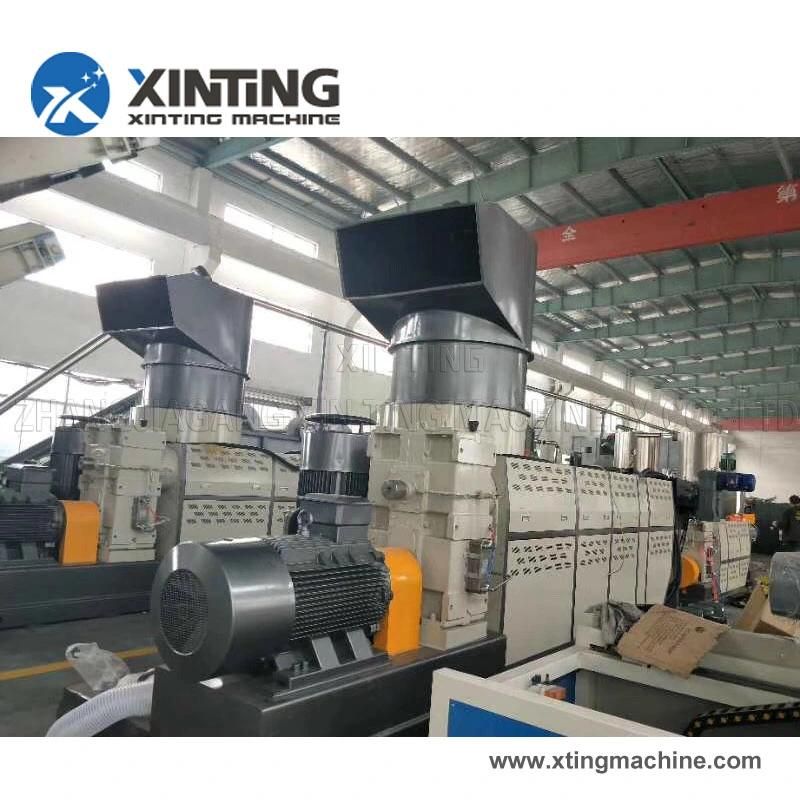

Model NO. pelletizing machine 180 Automation Automatic Computerized Computerized Customized Customized Certification CE, ISO9001:2008, QS, UL, GMP, BV Condition New Invertor ABB, Honeywell Motor ABB Screw Speed 0-115rpm Vibration System Stainless Steel Water Consumption According to The Capacity Screw L:D 10-35:1 Contact Water Part Stainless Steel Application Plastic Pelletizing Machine Control PLC+Touch Screen Business Type Manufacturer Product Name Plastic Pellet Making Machine Final Product Pellets/Granules Transport Package Film Package and Wood Case Package Specification optional Trademark XINTING Origin Zhangjiagang China HS Code 8477800000 Production Capacity 12 Lines Per YearProduct Description

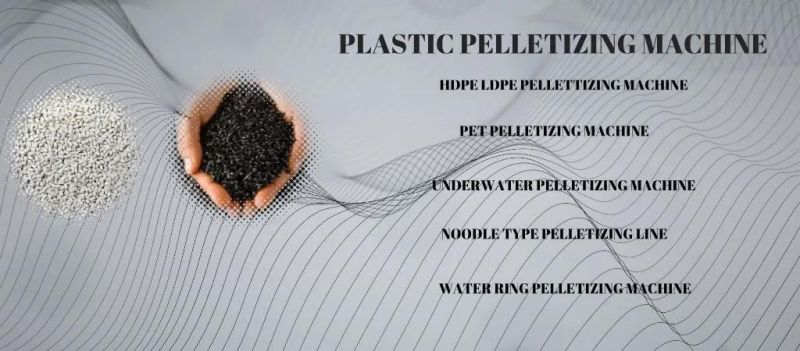

plastic PP PE LDPE HDPE BOPP Film Woven Bags Bottle Flakes Recycling Water Ring Noodle Type Single Screw /Double Stage Granules granulation Pelletizing Machine

plastic pelletizing machine was used to waste plastic recycling pellet.

Our machine use high efficinet compactor force feeder, excellent screw, strong vacuum degassing system ,fast hydraulic sceen change,Vertical die face cuttuer,automatic vibrator screen.

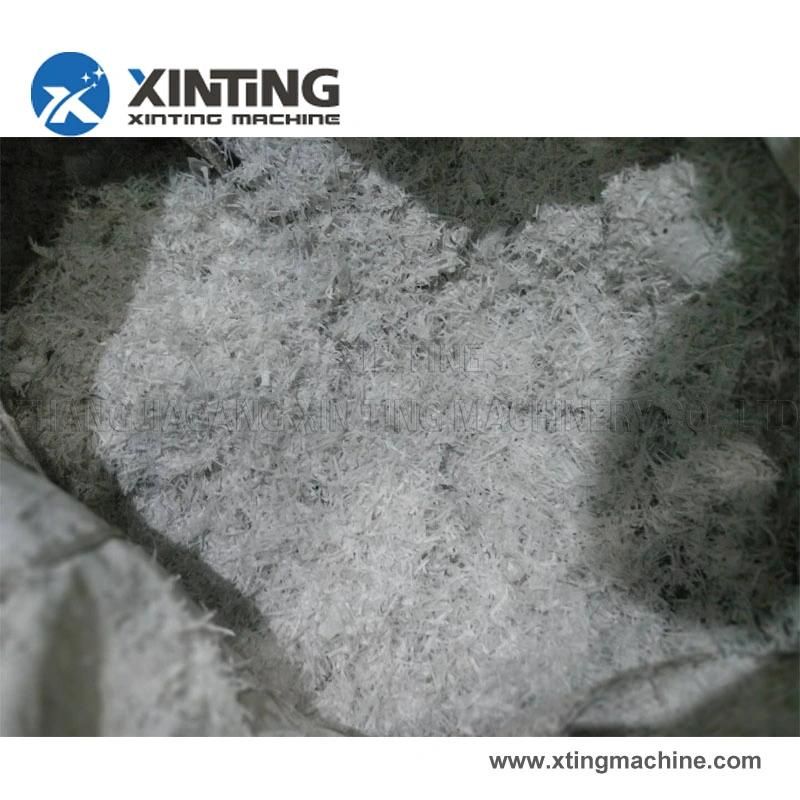

Raw material:

PP, HDPE, LDPE, LDPE,BOPP,PLA Film, Woven bags/Nonwoven bags/Jumbo bags/ Raffia bag material

Advantages:

1.Material will be cut, pre-heated,mixed and compacted by Compactor machine

2.Highly efficient, Less power consumption, Highly automatic

3.We supply single stage or double stage (Mother and baby type).

4. Supply 150~1000 kg/h or customized big capacity for customer.

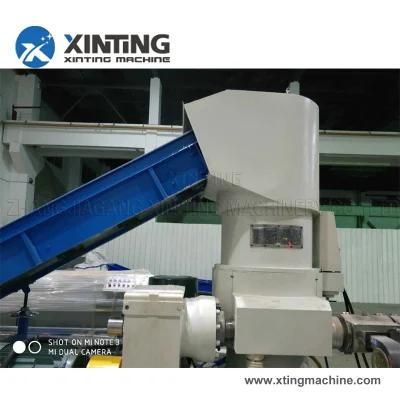

plastic pelletizing machine extruder layout:

1.Conveyor belt

2.Semi automatic metal detector

3.Compactor force feeder

4.The first stage extruder

5.Without Wire mesh filter hydraulic changer or hydraulic screen change+ vacuum degassing head

6.the second stage extruder

7.Standard hydraulic changer

8.Die face cutting system(vertical or horizontal)

9.Water cooling tank

10.Centrifugal dewatering machine

11.Vibrator screen machine

12.Air conveyor & Storage silo

Application of raw materials:

PET ,PE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS,XPS, PBT MATERIAL Stretch film, Non woven fabric, Woven bags,etc.

Flow chat of PP/PE plastic granules/pellets making machine:

Water ring granulating:

Conveyor → Film compactor → Single screw extruder → Die head and hydraulic screen changer →Water ring pelletizing → Water tank → Dewatering machine → Vibration sieve → Air blower → Storage silo

Features of granulator

High efficiency force-feeder ensures high capacity feeding, low energy consumption.

Extruder of PP/PE film pelletizing line: single stage or double stage pelletizing.

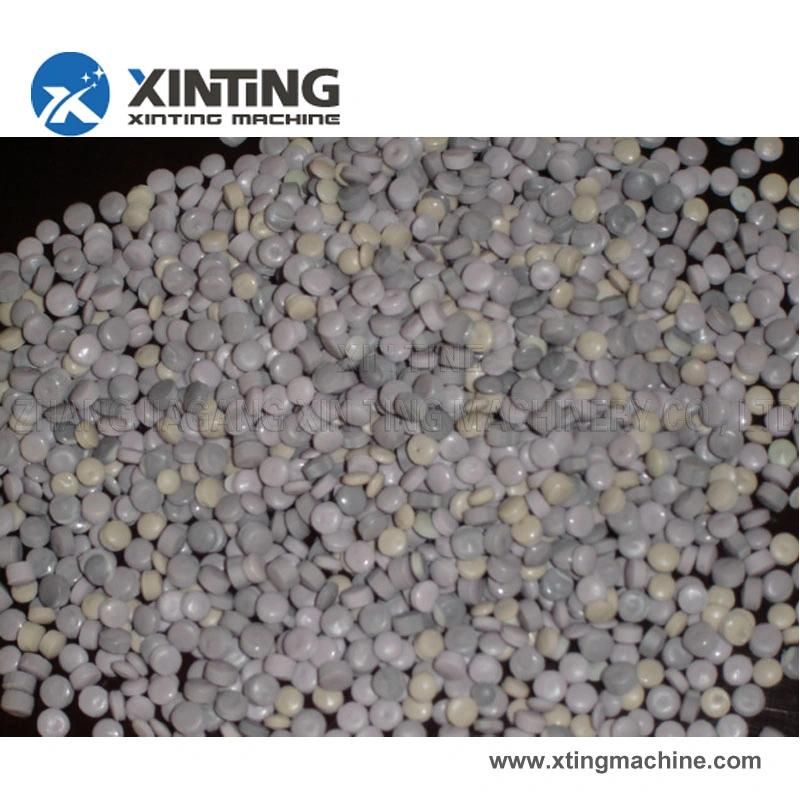

Pelletizing style: water-ring and water cooling strand cutting with extrusion mould, even cutting ensures good shape.

Main parameters PP/PE plastic granules:

| Extruder | SJ85 | SJ100 | SJ130 | SJ160 |

| Screw diameter | 85mm | 100mm | 130mm | 160mm |

| Main motor | 55kw | 90kw | 132kw | 160kw |

| Compactor power | 37kw | 55kw | 75kw | 90kw |

| Capacity | 100-180kg | 200-300kg | 300-400kg | 500-600kg |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23