Movable CIP Cart with Pump CIP Washing Unit

Hangzhou Xiaoju Trading Co., Ltd. / 2022-07-04

- Processing Material:SUS304 or 316L

- Application:Vegetable, Fruit, Dairy, Beverage, Beer, Wine, Food

- Customized:Customized

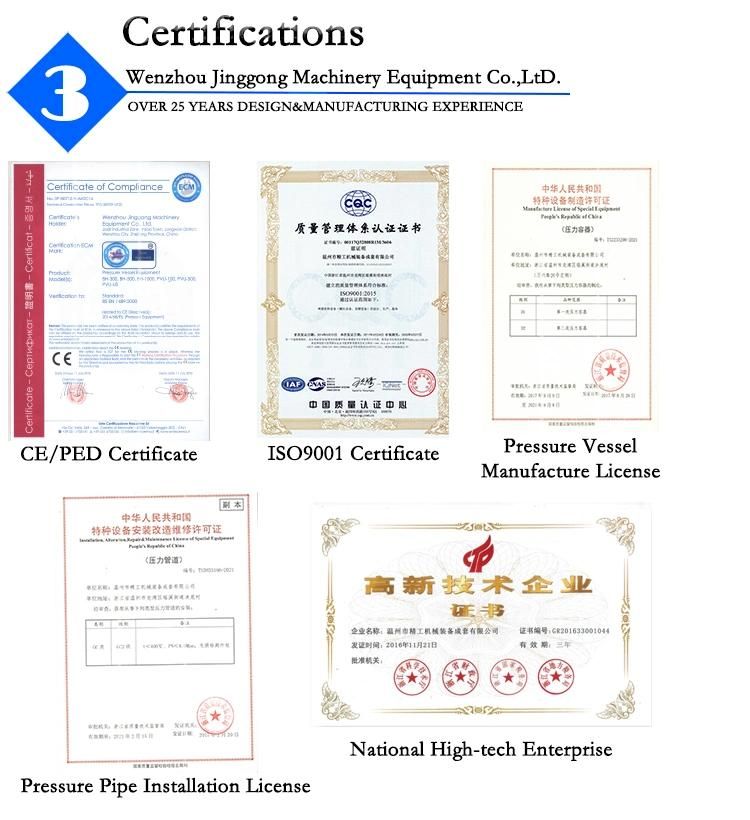

- Certification:CE, ISO9001, PED

- Power Source:Electric or Gas

- Automatic Grade:All Available

=== Base Info ===

- Transport Package:LCL or FCL

- Specification:100L~5000L

- Trademark:Jinggong

- Origin:Zhejiang, China

- HS Code:8438900000

- Production Capacity:20 Sets,Year

=== Description ===

Basic Info.

Transport Package LCL or FCL Specification 100L~5000L Trademark Jinggong Origin Zhejiang, China HS Code 8438900000 Production Capacity 20 Sets/YearProduct Description

Movable CIP cart with pump CIP washing unit

System introduction:

★ The complete CIP design for pure draft beer is divided into 4 parts: pre-filter cooling CIP, pre-filter heating CIP, post-filter cooling CIP, filtered hot CIP, and interception of cross-contamination.

★ This system not only considers the cleaning of tanks and pipelines but also the cleaning of the filtration system; the CIP tank itself can be self-cleaning.

★ The system can be manual, semi-automatic and fully automatic control: including temperature, pressure, liquid level, concentration, flow control.

★ The process includes: hot water washing, hot caustic washing, cold caustic washing, pickling, disinfecting liquid washing, water washing, deoxygenated water washing, brewing water washing and so on.

★ Major equipment: hot water tanks, hot caustic tanks, cold caustic tanks, acid tanks, disinfectant tanks, recovery tanks, brewing tanks, CIP transfer pumps, heaters, automatic acid-alkali addition pumps, conductivity meters, ultraviolet disinfection Etc.

Features:

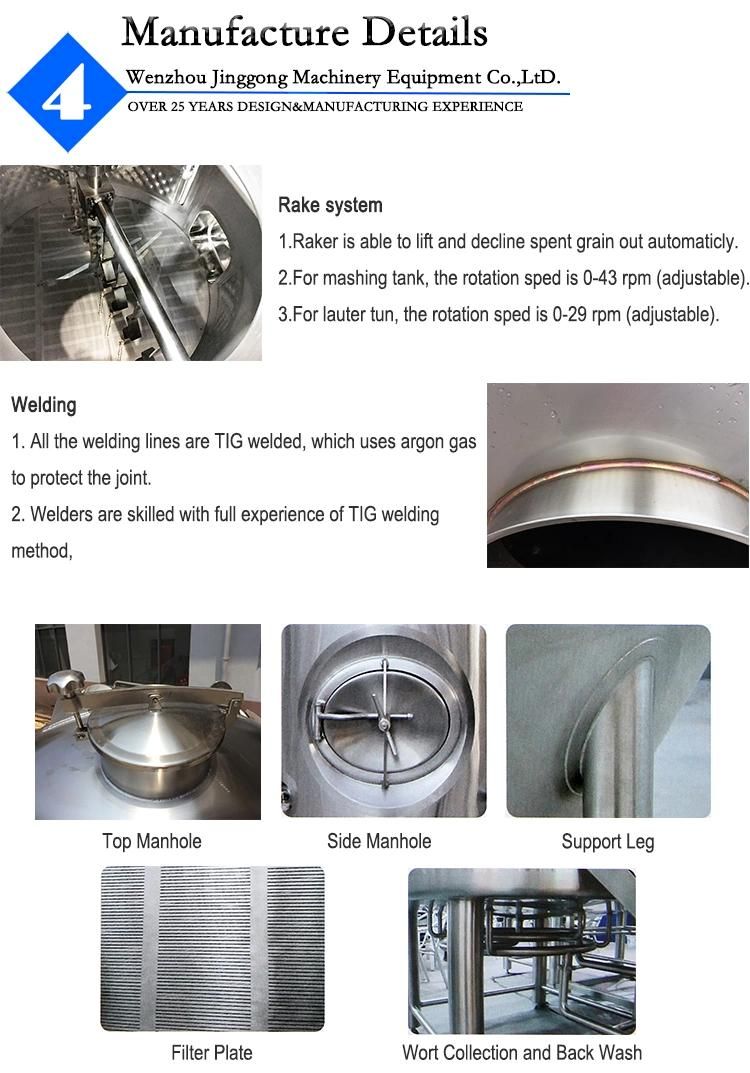

★ The design layout is reasonable, the equipments are made of imported 2B stainless steel material, the internal surface polishing is ≤ 0.4μm, the external surface is ≤ 0.8μm, and the overall appearance of the equipment is generous;

★ Recycle alkaline water and steam, save energy, meet the cleaning process requirements of various sections, and increase efficiency;

★ The operator only needs to configure the concentrated alkali solution and convert the CIP feed distribution plate for each shift; other tasks can be automatically controlled, manual monitoring is performed, and a touch monitor is provided to display all the system parameters of the intuitive CIP cleaning station and can be Cleaning process to facilitate the modification of parameters;

★ Automatically monitor the concentration of the washing liquid in the tank and automatically add the concentrated washing liquid;

★ Automatic monitoring of tank washing level, automatic water supplement;

★ automatic detection of reflux concentration, automatic selection of reflux or emissions;

★ Automatic control of the temperature of the liquid in the outlet, and the automatic control of the liquid material in the outlet.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23