Auto Combined Rice Milling Machine

Jiangsu Vichen Composite Material Co., Ltd. / 2022-07-05

- Type:Rice Mill

- Application:Flour, All, Beans, Wheat, Starch, Rice flour, Rice

- Voltage:380V

- Appearance:Vertical

- Press Materials:Rice

- Press Series:Second

=== Base Info ===

- Model NO.:SD-RMM

- Condition:New

- Customized:Customized

- Capacity:1000-1200kg,H

- Power:24kw, 380V, 50Hz

- Broken Rice Rate:3-5%

- Operation:Automatic

- Quality:High Quality

- Discount:Negotiable

- Weight:1400kg

- Installation:Responsible Installation

- Useful Life:20years

- Transport Package:Wooden Case

- Specification:Stainless steel

- Trademark:SIDA

- Origin:China

- HS Code:8437800000

- Production Capacity:1000 Sets Per Month

=== Description ===

General description of auto combined rice milling machine

1) This Small Combined Rice Processing Milling Machine includes: TQLQ50a Suction Stoning Machine, Husker, Gravity Paddy Separator, Jet-air Emery Roll Rice Mill, and broken rice grader, etc.2) It can clean, de-stone, hull, paddy separate, whiten( polish), grade all in one. The output is 1000-1200 kg rice per hour.

3) Features: a. The main advantage of this new machine is that it occupies small space for easy installation with good performance, making rice whiter with less broken rice. b. Compact structure, easy operation, high rice precision; It's a ideal machine for small investment with good finish product. c. The working video and details manual will be available. d. Easy to adding some follow-up equipment e. Better cleaning effect

It is a new type whole set combined rice mill for processing rice in farmlands, towns, grain shop and specialized households, and it can improve milling precision of rice according to the demands of users by adding some follow-up equipment, like polisher, color sorter and rice packing machine.

Detailed images of auto combined rice milling machine

Hot product

Combined rice mill machine can be formed a whole line with rice polisher machine, rice color

Combined rice mill machine can be formed a whole line with rice polisher machine, rice colorsorter machine, rice packing machine as following:

Popular and hot sale Complete set of 1000-1200kg/h rice processing line

This set of whole rice processing line includes combined rice milling machine(which includes cleaner, de-stoner, husker, paddy separator, rice mill and grader all in one), water polisher, white rice grader, color sorter and rice packing machine.

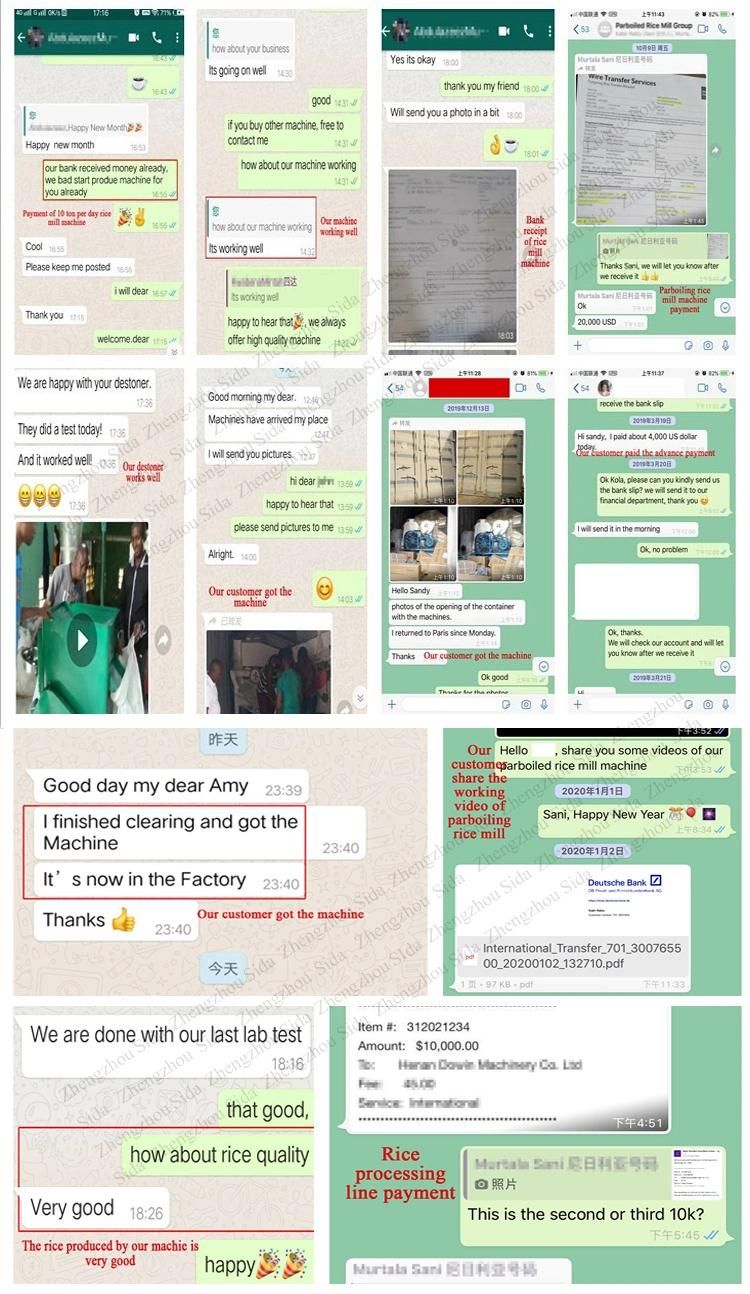

The whole processing line will be linked with some elevators with each other, so that this rice milling line is automatic working, high efficient and labor-saving!Customer feedback

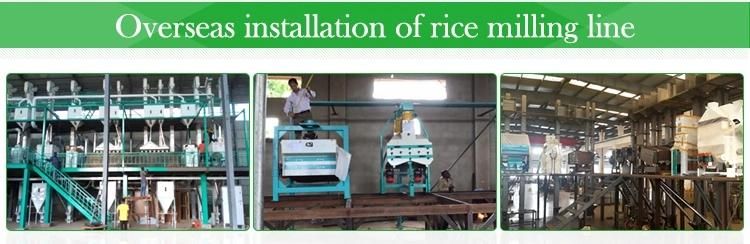

Installation pictures

Packaging and shipping of auto combined rice milling machine

Company information

Our service of auto combined rice milling machine

Pre-sale service of auto combined rice milling machine

- 1. Accept customer consultation, We will offer solutions according to customer requirements, determine the scale of operation;

- 2. To provide customers with project design, process design, suitable for your machine equipment plan formulation of choose and buy, in a timely manner to provide customers with related technical documents; According to your special requirements, design and manufacture of products, for your training technical operation personnel for preliminary design and construction design.

Serve for sale of auto combined rice milling machine

- 1. The company sent technical personnel to the scene of the on-the-spot guidance equipment installation, debugging and training operators

After-sales service of auto combined rice milling machine

- 1. Phone support: refers to the customers in the use of equipment of difficult problems in the process or equipment in abnormal state, by telephone or by fax to the company for technical support and help. Company after confirm the customer's service request, will arrange technical personnel within the prescribed period of time (i. e., response time) by phone to help fault locating the demand side, and put forward solutions, guide customers to exclude equipment failure in the end.

- 2. If you can't fault diagnosis by phone and solve the failure phenomenon, will immediately send technicians to the scene, eventually to solve.

- 3. The company's products provide a year warranty, life-long maintenance.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23