Castor Oil Pressing Equipment Refinery Machinery

Shenzhen Xiangfeizhu Technology Co., Ltd. / 2022-07-05

- Type:Spiral Oil Press

- Application:Beans

- Voltage:220V

- Appearance:Vertical

- Press Materials:Castor

- Press Series:Second

=== Base Info ===

- Model NO.:Huatai-Sesame

- Condition:New

- Customized:Customized

- Transport Package:Bulk

- Specification:Customized

- Trademark:None

- Origin:China

- HS Code:84792000

- Production Capacity:20 Set,Year

=== Description ===

Basic Info.

Model NO. Huatai-Sesame Condition New Customized Customized Transport Package Bulk Specification Customized Trademark None Origin China HS Code 84792000 Production Capacity 20 Set/YearProduct Description

Castor oil is a vegetable oil pressed from castor beans. The name probably comes from its use as a replacement for castoreum.

Castor oil is a colourless to very pale yellow liquid with a distinct taste and odor. Its boiling point is 313 °C (595 °F) and its density is 961 kg/m3. It is a triglyceride in which approximately 90 percent of fatty acid chains are ricinoleates. Oleate and linoleates are the other significant components.

Castor oil and its derivatives are used in the manufacturing of soaps, lubricants, hydraulic and brake fluids, paints, dyes, coatings, inks, cold resistant plastics, waxes and polishes, nylon, pharmaceuticals and perfumes.

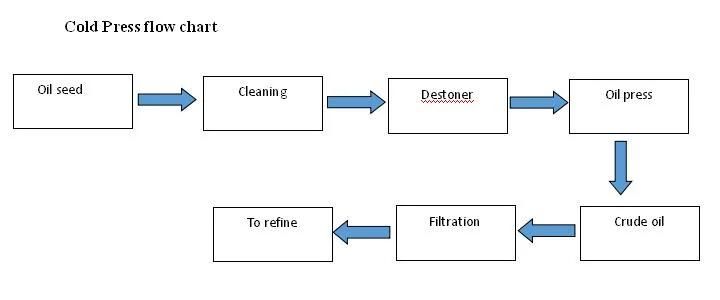

Process diagram

Part of the Equipment

Company information

Our company was estabished in 1950s ,now is one of the big oil equipment supplier in China .We have our own R&D department and installation service team with rich experience .

We have successfully obtained 27 national patents (7 invention patents), 6 international medals, 2 state awards, 2 provincial prizes Our machines sell well in more than 30 provinces, and exported to Egypt, Sudan, Tanzania, Rwanda,Nigeria,Estonia,Russia,Kazakhstan,Uzbekistan,Tajikistan,Bangladesh,Thailand,Malaysia,Indonesia, Bolivia,Peru and so on.Now we have developed into a major oil machinery manufacture base in China.

Our main project scope include

--10~5000TPD oilseed pretreatment project

--20~5000TPD solvent extraction project

--10~500TPD oil refining project

--10~500TPD oil fractionation project

--Protein and phospholipid project

--Grain processing project

Typical project

--10~1000TPD rice bran pretreatment & expansion and rice bran oil extraction project

--10~600TPD grade 1 rice bran oil refining project

--150~1000TPD cottonseed protein dephenolization project

--10~100TPH palm oil project

--10~2000TPD corn processing project

--10~500TPD non-acid catalysis biodiesel project

Latest Technology

--Oil deodorization and vacuum energy-saving technology

--Protein concentrate extraction technology

--Miscella refining technology

--Molecular distillation technology

--Extracting sugar from broken rice technology

--Fully-continuous lignite wax extraction technology (the first production line in Asia)

Engineering design scope&After-selling service scope

1). Craft flow chart

2). Equipment layout drawing;

3). Equipment base drawing;

4). Reserved hole & embedded parts drawing and civil engineering condition drawing;

5). Embedded pipeline layout drawing;

6). Embedded pipeline of power circuit drawing

7). Power electricity layout drawing;

8). Electricity distribution cabinet and operation table schema;

9). Plant layout drawing

10). Equipment installation & commission guidance and training work:

Contact Us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23