Belt Chocolate Coating Machine

Hubei Hawking Packaging Material Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Coating

- Automatic Grade:Automatic

- Application:Chocolate

- Customized:Non-Customized

=== Base Info ===

- Model NO.:DR-TYJ-II

- Transport Package:Wooden Case

- Specification:250kgs,hour

- Trademark:D&R

- Origin:China

- HS Code:8438200000

- Production Capacity:300PCS,Year

=== Description ===

Basic Info.

Model NO. DR-TYJ-II Transport Package Wooden Case Specification 250kgs/hour Trademark D&R Origin China HS Code 8438200000 Production Capacity 300PCS/YearProduct Description

Belt Chocolate Coating MachineThis machine is advanced equipment for chocolate coating, especially for chocolate bean, melon, nuts, dry fruit and so on. The machine is automatically controlled by the PLC program, installed with a system of recipe save and automatic weighing. The flow of chocolate mass, the capacity of cold wind, the speed of mesh belt moving are adjustable

- process time: 40-50min/batch, humidity of air should be 45-55% (The process time is based on the material of coating layer and products which need to coat, the temperature of air and humidity inside of the machine.).The weight of coated products is about 250kgs.

- Capacity

B. Raisin 120kgs/batch, coating time:60 minutes

C. Almond 80kgs/ batch, coating time:60 minutes

3. Size: 2200*1550*2030mm.

Characteristic

- Stainless steel structure for wash easily.

- Full automatic and exact chocolate coating metering valve.

- Jacket chocolate sprinkler system with tip cleaner to make sure the nozzles will not be blocked.

- There are lights in the machine.

- Convenient and detachable system for recovery of scrap material.

- There are four legs with the automatic weighing system(loadcell).

- There is a chocolate mass adjustment valve to control the flow rate of chocolate mass.

- Power of the main motor is 3KW. There are a 50L hot water tank and a water pump for the insulation system of the coating machine. Most of the parts including the frame, cover and the parts which contact with products(except plastic conveyor belt) are ss304.

- Electric components are Siemens or Schneider brand. Control system is the Delta brand(PLC).Chinese brand motor with gearbox. The pneumatic system is Airtac.

- It should work with one 500L chocolate storage tank, one chocolate feeding pump(speed adjustable), hot water tank, jacket pipes and hot water tank.

Working condition:

1. Electricity: 380V.

2. Temperature 26ºC, relative humidity 45-55%.

3. Recycle hot water with temperature 40ºC-50ºC.

4. Supply of cold wind

Detailed Images:

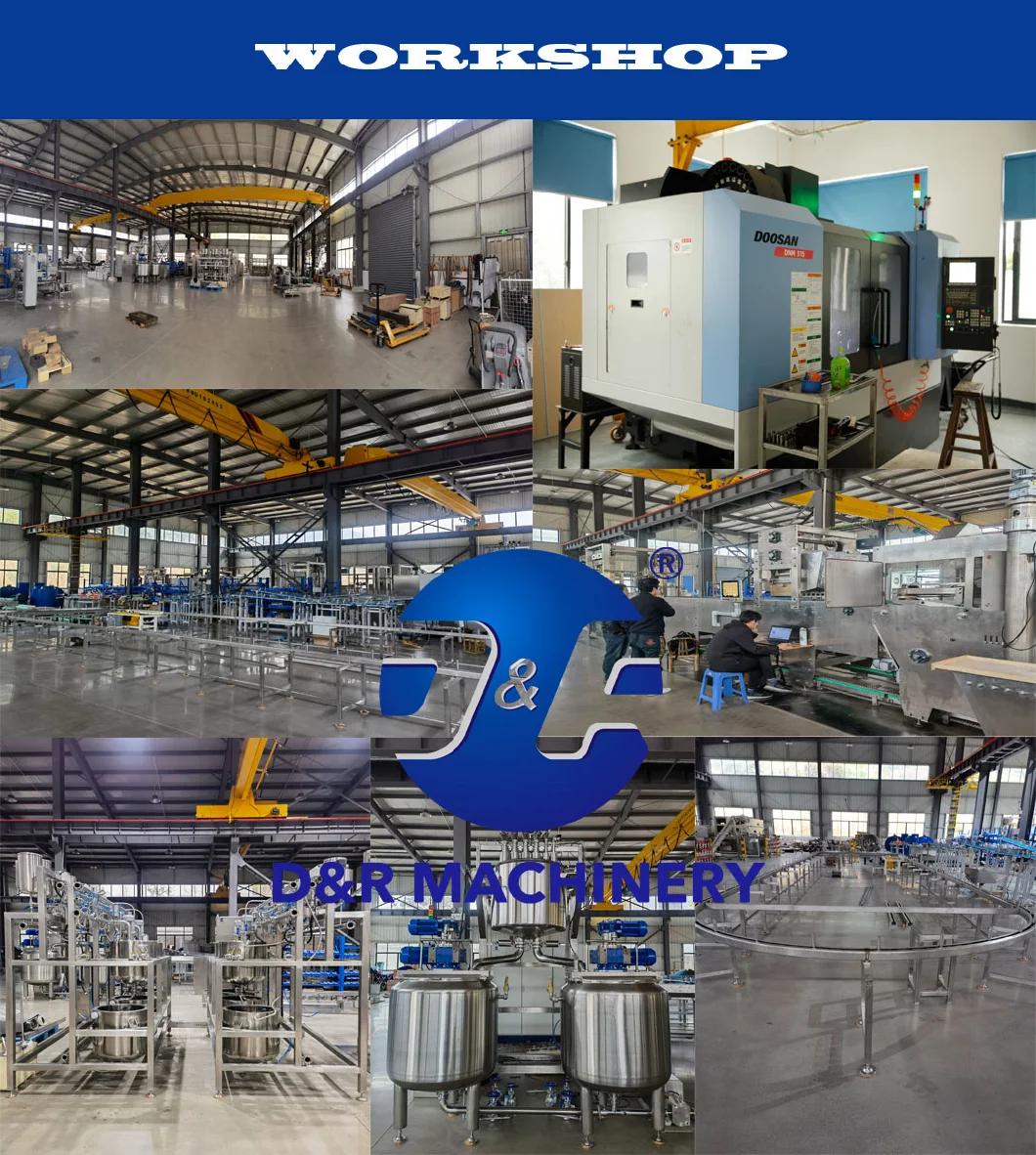

Company Introduction:

TOTAL SOLUTION ,TOTAL CARE

D&R Machinery are professional confectionery machine manufacturers with over 10 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23