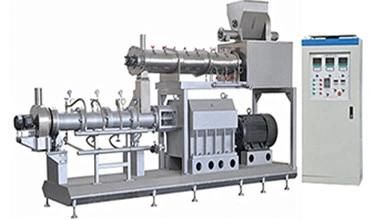

Extrution Food Floating Fish Feed Production Line

ZheJiang Kincess Innovative Materials Co., Ltd. / 2022-07-05

- Processing Material:Grain Powder or Others

- Application:Pet Food Factory

- Customized:Customized

- Certification:CE, SGS

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:Hm-70

- Condition:New

- Capacity:200-250kg,H

- Voltage:380V, 50Hz, 3phases (Adjustable)

- Control System:PLC

- Delivery Detail:25 Working Days After Receiving Deposit

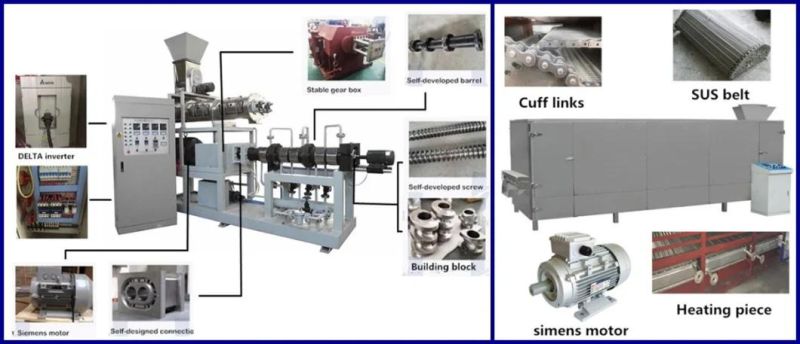

- Motor:Siemens, ABB or China Famous Brands

- Power:50kw

- Machine Material:Food Grade Stainless Steel

- Product Name:Pet Food

- Need Worker:2-3 Workers

- Warranty:1 Year

- Transport Package:Inside Plastic Bag, Outside Wooden Case

- Specification:24000*1500*2200mm

- Trademark:HIMAX

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:50sets,Month

=== Description ===

4.Detail of the machine parts

Mixer

Vertical stirrer are able to perform even mixture for large volume of materials in short mixing time by utilizing the paddles rotation to gather the material from the bottom of dump center to the top, shed the material flow back to the bottom and complete the mixing in short period of time

Screw Conveyor

It can hoisting the mixed material from the mixer into the extruder machine

Double Screw Extruder

Extruding the mixture into different shapes of dog food,fish feed based on different parameters

(INCLUDING: storage bin, Double Axis Conditioner for pre cooked, Support Platform, Center Cutting System 2 Free Moulds)

Dryer

This kind of oven has a wide range of application. It can dry all shapes of puffing food, including strip, lump, granular materials etc, as well as other types of materials.

Spray-spraying machine

To make food overturning inside the coating drum,

to catch more oil and flavors. The materials, flavoring and oil are stirred and mixed in the roller until well distributed.

Cooling Machine

Mainly applicable to a varitey of granular material cooling.

Adopted countercurrent cooling principle, full cooling and unformity.

5.Quality Control

7.Company Information

Jinan Himax Machinery Co., Ltd. is a professional supplier of food processing machines for 12Years. We have many kinds of machines and production line, such as food extrusion machine, soya meat production line, industrial microwave oven, packaging machine, pet food production importantly, we also provide formulas, technology supports, machine inspection s

Jinan Himax Machinery Co., Ltd. is a professional supplier of food processing machines for 12Years. We have many kinds of machines and production line, such as food extrusion machine, soya meat production line, industrial microwave oven, packaging machine, pet food production importantly, we also provide formulas, technology supports, machine inspection service, etc. Cooperating with different manufacturers and research centers, we provide the food processing machines with outstanding quality. We have a group of experienced experts and outstanding engineers who do provide the professional service ,delivery and installation. Based on the clients specific requirement, we also OEM machines for our clients.

8.Our Srevices

-- Before sale service

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

--Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout

2.Welcome to visit our factory or the domestic clients' factory.

3.Inspect the machine before leaving the factory.

--After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula.

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. 1-2 engineers will be arranged for custom

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23