Lotus Leaf Microwave Leaves Dryer

Xiamen Hongxincheng Rubber&Plastic Products Co., Ltd. / 2022-07-05

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Semi-Automatic

- Type:Drying

- Voltage:220,380 V

- Customized:Customized

=== Base Info ===

- Model NO.:KLD-LMTD

- Name:Lotus Leaf Microwave Leaves Dryer

- Color:Silver Gray

- Function:Drying

- Feature:Low Energy High Speed

- Control System:PLC

- Raw Material:Stainless Steel

- Cooling System:Water Cooling

- Transmission Speed:0-10 M,Min (Adjustable)

- Capacity:120-2500 Kg,H

- Application:Lotus Leaf Microwave Leaves Dryer

- Transport Package:It Is Usually Packed in Plastic Film, We Also Can

- Trademark:KLD

- Origin:China ( Mainland ) Shandong

- HS Code:843880000

- Production Capacity:120-2500 Kg,H ( Customized )

=== Description ===

Basic Info.

Model NO. KLD-LMTD Name Lotus Leaf Microwave Leaves Dryer Color Silver Gray Function Drying Feature Low Energy High Speed Control System PLC Raw Material Stainless Steel Cooling System Water Cooling Transmission Speed 0-10 M/Min (Adjustable) Capacity 120-2500 Kg/H Application Lotus Leaf Microwave Leaves Dryer Transport Package It Is Usually Packed in Plastic Film, We Also Can Trademark KLD Origin China ( Mainland ) Shandong HS Code 843880000 Production Capacity 120-2500 Kg/H ( Customized )Product Description

Lotus Leaf Microwave Leaves Dryer

Product Overview Introduction of microwave:The microwave is an electromagnetic wave has a frequency of 300MHz-300GHz. The moisture in the heated mediu are polar mocules, under the cation of rapidly changing high-frequency electromagnetic fields, their polar orientation will change with the change of the external eletric field, causing molecular motion and mutual friction effects. At this time, the field energy in the microwave field is converted into thermal energy in the medium, so that the temperature of the material is increased, and a series of physicochemical processes of the heating and expansion are fenerated to achieve the purpose of microwave heating and drying.

Application of microwave machinery:

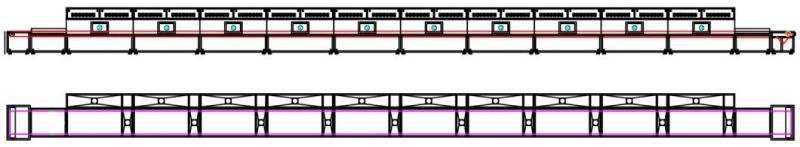

This equipment is mainly used for food drying, sterilization, heating, curing, etc. It can also be used for drying, extraction and heating in the pharmaceutical and chemical industries. Equipment structure diagram:

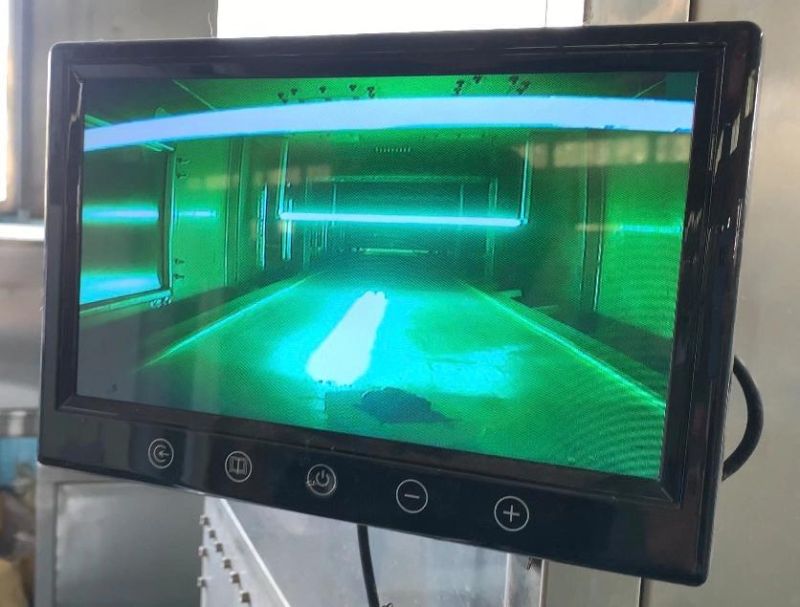

Detailed pictures:

Adopt high-definition color display screen, workers can observe the inside of the tunnel at any time.

Adopt high-definition color display screen, workers can observe the inside of the tunnel at any time.

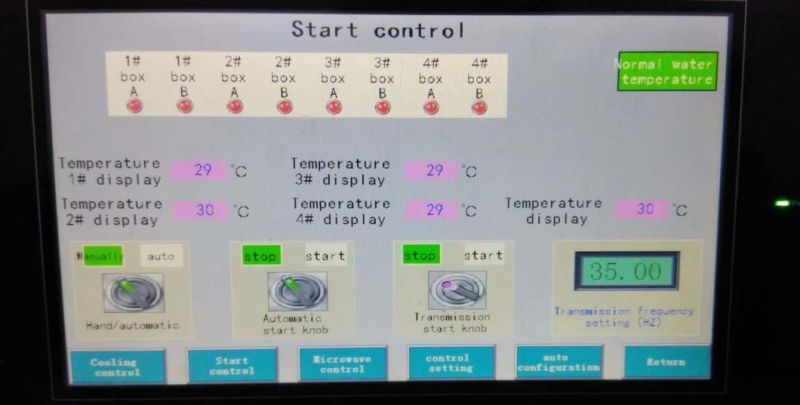

Adopt Programmable Logic Controller (PLC) and sensitive touch screen make the operation of the machine simple and easy.

There are two kinds of operating mode, can be setted in the operating system, automatic mode and manual mode. In the automatic mode, workers only need to check the operation of the equipment without operating the equipment, which can greatly reduce labor costs.

The conveyor belt and opening can be selected according to the characteristics of raw materials.

Water-cooled magnetron for continuous non-stop operation.

This is air-cooled magnetron, can not work without interruption, but the price is lower than water-cooled magnetron. This type of magnetron is suitable for low power machine, or the areas with low ambient temperature.

Features and advantages

Features and advantages of the microwave drying machine:

1. Efficient: Microwave can make the product produce heat effect very fast, the material will be heated for a short time, to avoid cause some unnecessary chemical reaction of the material.

2. High quality of finished product: Microwave sterilization can keep the product's color, fragrance, taste, physical appearance, and nutritional components, etc, to the maximum.

3. Safety: This machine is specially designed without microwave leakage.

4. Environment friendly: Adopt clean energy electricity as power source, it does not pollute the environment.

5. Easy operation: The operation is simple, stable, safe and friendly.

Machine Parameter

| Model | Installed Power (KW) | Drying Capacity (kg/h) | Dimension (mm) |

| KLD-10GZ | 10 | 10 | 7010*840*1750 |

| KLD-20GZ | 20 | 20 | 9350*840*1750 |

| KLD-30GZ | 30 | 30 | 11690*840*1750 |

| KLD-40GZ | 40 | 40 | 10520*1060*1750 |

| KLD-50GZ | 50 | 50 | 11690*1060*1750 |

| KLD-60GZ | 60 | 60 | 12860*1060*1750 |

| KLD-70GZ | 70 | 70 | 14030*1060*1750 |

| KLD-80GZ | 80 | 80 | 12680*1200*1750 |

| KLD-100GZ | 100 | 100 | 15200*1200*1750 |

| KLD-150GZ | 150 | 150 | 21050*1200*1750 |

| KLD-200GZ | 200 | 200 | 25050*1200*1750 |

FAQ

Q.What's the power source of the machine?

A: Eletricity

Q. What's the main matrial of the machine?

A: SUS

Q: What's the voltage of the machine?

A: The voltage can be designed base on your local voltage.

Q: What's the demension of the machine?

A: Machines with different power have different dimension. Bigger power, bigger dimension.

Company Information

Jinan Kelid Machinery Co., Ltd.

We are a food producing and processing machinery supplier with many years experiences. We are committed to providing our customers with high grade machinery and ihtegrated services. Our main products include Puffed snacks/Core filling snack production line, Corn flakes/Breakfast cereals production line, Pasta/macaroni production line, Kurkure/Cheetos/ production line, Nutrition rice/Artificial riice production line, Nutrition powder/Modified starch production line, Breadcrumb production line, Instant noodles production line, Cereals bar production line, Pet food/Fish feed production line, Soya protein production line and Microwave drying&sterilization machine. Look forward to working with you!

Part Of Client Case

Contact Us:

If you have any questions of the machine, welcome to consult us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23