Paddy Dehuller Rice Thresher with Two Wheels

Taizhou Jiada Import & Export CO., Ltd. / 2022-07-04

- Type:Thresher

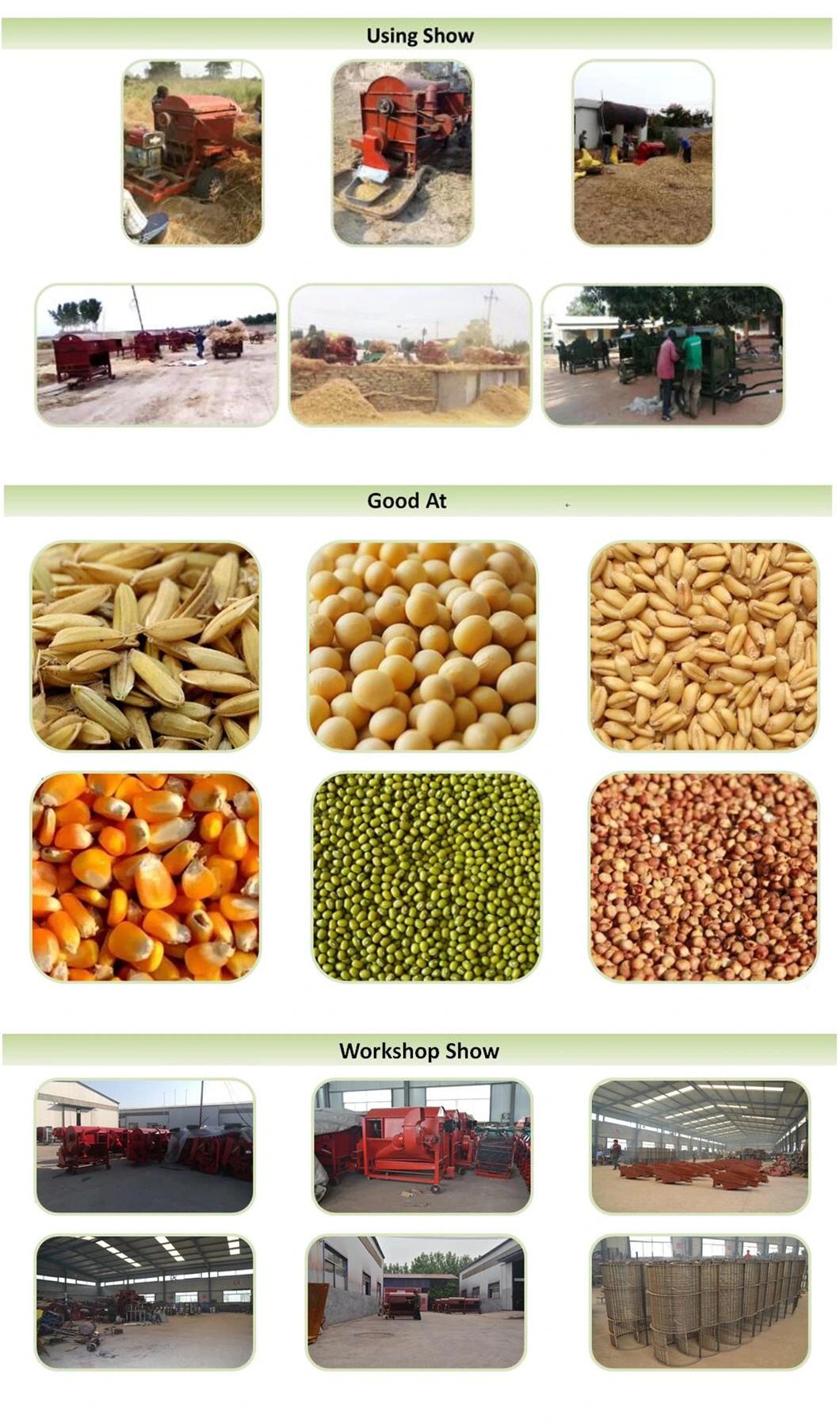

- Application:All, Beans, Wheat, Rice flour, Sorghum Soybean

- Voltage:380V

- Appearance:Vertical

- Press Materials:Soybean

- Press Series:Second

=== Base Info ===

- Model NO.:5TD

- Condition:New

- Customized:Customized

- Drive:Motor , Diesel Engine

- Power:12-15HP,7.5kw

- Capacity:800-1000

- Weight:230

- Spindle Speed:1200

- Dimension:1340*2030*1380

- Remark:Paddy, Soybean, Wheat, Sorghum

- Order:Customized

- Transport Package:Wooden Case , Container

- Specification:1340*2030*1380

- Trademark:KUDOU

- Origin:China

- HS Code:8433599090

- Production Capacity:100set Per Month

=== Description ===

Basic Info.

Model NO. 5TD Condition New Customized Customized Drive Motor / Diesel Engine Power 12-15HP/7.5kw Capacity 800-1000 Weight 230 Spindle Speed 1200 Dimension 1340*2030*1380 Remark Paddy, Soybean, Wheat, Sorghum Order Customized Transport Package Wooden Case / Container Specification 1340*2030*1380 Trademark KUDOU Origin China HS Code 8433599090 Production Capacity 100set Per MonthProduct Description

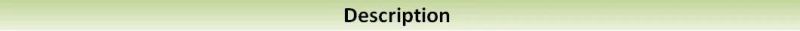

Paddy dehuller rice thresher with two wheels

| Model | Power (HP) | Capacity (kg) | Weight (kg) | Spindle Speed(rpm) | Dimension(L*W*Hmm) | Remark |

| 5TD-50 | 6-8 | 500-800 | 150 | 1500-1800 | 1030*890*1630 | Paddy, soybean, wheat, rapeseed |

| 5TD-75 | 12-15hp/7.5KW | 800-1000 | 230 | 1200 | 1340*2030*1380 | Paddy, soybean, wheat, sorghum |

| 5TD-100 | 12-15hp/7.5KW | 800-1500 | 280 | 1100 | 2300*1570*1170 | Paddy, soybean, wheat, sorghum |

| 5TD-125 | 22hp/11-13KW | 1200-2000 | 400 | 1050 | 2500*1770*1550 | Paddy, soybean, wheat, sorghum |

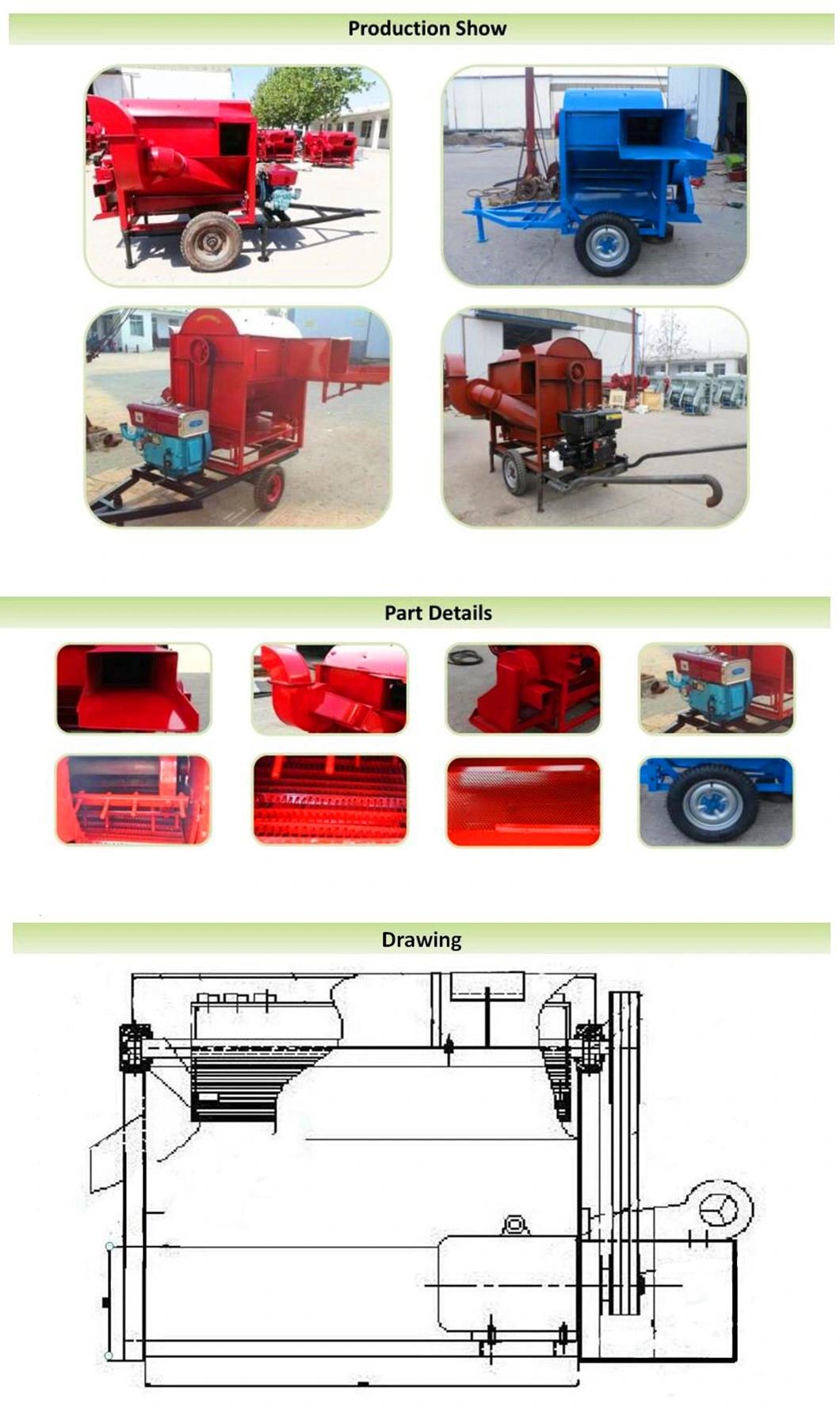

The thresher is mainly composed of a feeding table, a frame, a concave screen, a detaching drum, a cover, a guide plate, a fan, a vibrating screen and a transmission device. The breaking rate is low, the removal rate is high, and the loss rate is low, which can be removed once and does not need to be removed. Well received by the majority of users.

Instructions for use:

1. Before starting the machine, check the bolt fastening condition of each part; if there is any resistance to the roller, confirm that everything is normal and drive for 3-5 minutes.

2. The threshing machine triangle belt should not be too tight or too loose; after starting the power machine, first confirm whether the drum steering is consistent with the marking on the machine.

3. After starting the machine, the operator should be more than 2 meters away from the machine. After the machine is running normally, the crop can be fed.

4. The threshing crop should be unbundled, continuously and evenly fed. It should not be too large or too high to prevent the feed inlet from being blocked.

5. Pay attention to the bearing temperature during use, and add lubricant to the bearing at regular intervals.

6. After the drum and fan impeller are damaged, they should be repaired in time. The replacement drum and impeller must be balanced.

Pre-sales Service

1. Technical Consulting Service

Our wide product range enables us to provide most flexible, efficient and reliable equipment configurations or complete solutions for customers according to different requests and budgets.

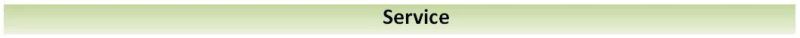

2. Company and Production Line Visit

Before placing orders, customers are warmly welcome to visit factory and our facility. We can also arrange the visit to our existing customers to learn the operation condition of our machines and complete plant.

In-sales Service

1. Reliable delivery time.

2. Strict quality control by in-production 100% check and test.

3. User manual and spare parts provided for free.

4. Transportation(EXW/FOB/CIF/C&F/CFR/DDU/DDP)

After-sales Service

1. Fast technical guidance for construction, installation and commissioning.

2. Necessary training for daily maintenance on site.

3. 12 months warranty.

4. Lifelong regular technical service.

5. Timely solutions to problems.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23