Tsd Automatic Plastic Sheet Bending Machine

Jinjiang Jiaxing Import and Export Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

chemical containers, sewage treating pipe, ventilation systems and so on.

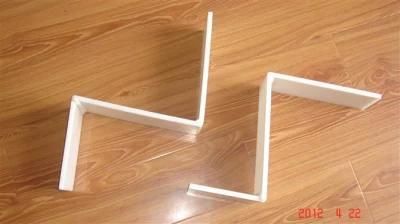

TSD Plastic bending function operation

1. Knife adjustment: adjust the adjusting screw fixed at both ends of the layer plate to level the gap between the upper knife and the lower knife, gap is 3 mm or so normally.

2. The angle adjustment of the flap : adjust the magnetic switch of cylinder to make a right angel.

Operation Steps:

A. The using temperature of the upper knife is 175 degrees , the using temperature of the lower knife is about 120 degrees.

B. Start the machine after heating for about half an hour.

C. Firstly, press the Clamping-up switch,then put in the plastic board and certain the size, press the clamping-down switch to let down the clamping piece. Secondly, press the Layer-forth switch to make the upper knife reach the location where it's going to be folded.Thirdly, press the Knife-close switch to descend the upper knife and lifting the lower knife. No sooner than the contacting part of the plastic board and the upper knife has been melted about 1/2 to 3/4 ,press the Knife- separation switch.

At last, press the Layer-back switch ,then the layer board will be back and the turning board will be up. When the angle is formed and cooled , press the Turning-down switch and the Clamping-up switch.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23