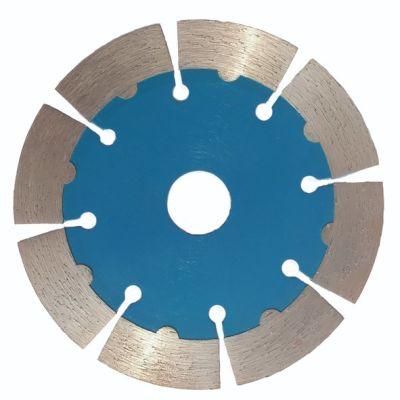

China Supplier Protection Teeth Diamond Saw Blade for Concrete 4.5"Hot Sale Cutting Tools

Ningbo Furuidi Packaging Products Co., Ltd. / 2022-06-27

- Blade Type:Cutter Head

- Manufacturing Process:Sintered

- Application:Stone

- Technology:Welding

- Body:Normal

- Size Range:115mm

=== Base Info ===

- Model NO.:4-4.5′

- Height of Segmented:2.0*15mm

- Arbor:20,22.23mm

- Color:Any

- Paiting:Color Paiting , Picture Paiting

- Transport Package:Standard Packing

- Specification:4.5"

- Trademark:oem

- Origin:Hebei, China

- Production Capacity:10000PCS,Month

=== Description ===

ITEM NO.

1. High quality grade of diamond

2. Dry / Wet both

3. 75Cr1 body

4. Hot pressed sintered technology and long servcie life

5. Cutting fast and smooth

6. Accurtate cutting with small calsts

Diamond Saw Blade Applications

Concrete, granite, marble, brick and other materials.

Machinery:

Angle grinder, circular saw, masonry saw, table saw.

Different model can be customized as wish.

Our Advantage:

We are the factory, can adjust different quality according different cutting demand, including OEM. Now we promise all produce machines are most advanced level, mostly are full-automatic, another important point is we promise all raw materials are original, and supply by famous named partners.

Products show :

Packing show :

Delivery show :

Shipping way :

What are the factors that affect the working condition of diamond saw blade?

Particle size

The grain size of commonly used diamond ranges from 30/35 to 60/80. The harder the rock, the finer particle size should be selected. Because under the same pressure, the thinner the diamond is, the sharper it is, which makes it easier to cut into hard rock. In addition, the general large diameter saw blade requires high cutting efficiency, it is appropriate to select the use of coarser particle size, such as 30/40, 40/50; The sawing efficiency of small diameter saw blade is low, and the sawing section of rock is required to be smooth, so it is advisable to choose a finer particle size, such as 50/60 and 60/80.

Concentration of the cutting tools

The so-called diamond concentration refers to the density of the diamond distribution in the working layer (that is, the weight of the diamond contained in the unit area). The "Code" specifies a concentration of 100 per cent for 4.4 carat diamonds and 75 per cent for 3.3 carat diamonds per cubic centimeter of working tyre body. Volume concentration indicates the amount of diamond in the aggregate volume, and specifies that when the volume of diamond accounts for 1/4 of the total volume, the concentration is 100%. Increasing the diamond concentration is expected to prolong the life of the saw blade because the average cutting force applied to each diamond is reduced by increasing the concentration. However, increasing the concentration will inevitably increase the cost of the saw blade, so there is an economic concentration, and the concentration increases with the sawing rate.

The hardness of the cutting tools

In general, the higher the hardness of the binder, the stronger its wear resistance. Therefore, when sawing large abrasive rock, the hardness of the binder should be high; When sawing soft rock, the hardness of the binder should be low; When sawing abrasive and hard rock, the hardness of the binder should be moderate.

effect

In the process of cutting stone, diamond circular saw blade is subjected to alternating loads such as centrifugal force, sawing force and sawing heat.

The grinding damage of diamond circular saw blade is caused by force effect and temperature effect.

Force effect: In the sawing process, the blade is subjected to the action of axial and tangential forces. Because of the force in the circumferential direction and the radial direction, the saw blade is wavy in the axial direction and dish in the radial direction. These two kinds of deformation will cause the rock section is not straight, stone waste, sawing noise, vibration aggravation, resulting in the early damage of diamond lump, saw blade life reduced.

Temperature effect: According to the traditional theory, the influence of temperature on the process of saw blade is mainly manifested in two aspects: one is to lead to graphitization of diamond in agglomeration; The other is the thermal stress between the diamond and the embryo, which leads to the premature shedding of diamond particles. New research shows that the heat generated during the cutting process is mainly transmitted to the lumps. The temperature in the arc area is not high, generally between 40 and 120ºC. However, the grinding point temperature of abrasive particles is relatively high, generally between 250 ~ 700ºC. The coolant only reduces the average temperature in the arc, but has little effect on the temperature of the abrasive particles. This temperature does not lead to graphite carbonization, but will make the friction properties between the abrasive particles and the workpiece change, and make the thermal stress between diamond and additives, and lead to a fundamental change in the failure mechanism of diamond. The results show that temperature effect is the main factor that causes the blade breakage.

Wear breakage: due to the force effect and temperature, saw blade after a period of use will often produce wear breakage. The main forms of grinding damage are as follows: abrasive wear, local crushing, large area crushing, shedding, mechanical abrasion of binder along the direction of sawing speed. Abrasive wear: diamond particles and the type of constant friction, edge passivation into a plane, loss of cutting performance, increasing friction. Thin layers of graphitization appear on the surface of diamond particles due to sawing cutting heat, which greatly reduces the hardness and intensifies wear. As the surface of diamond particles bears alternating thermal stress and alternating cutting stress at the same time, fatigue cracks will appear and local breakage will occur, and sharp new edges will be revealed, which is an ideal wear pattern. Large area crushing: diamond particles bear impact load when cutting in and out, and relatively prominent particles and grains are consumed prematurely; Exfoliation: Alternating cutting forces make the diamond particles in the binder are constantly shaken and loosening. At the same time, the wear of the binder itself and the sawing heat soften the binder. This reduces the holding force of the binder, and when the cutting force on the particles is greater than the holding force, the diamond particles will fall off. No matter which kind of wear is closely related to the load and temperature of diamond particles. Both depend on the sawing process and cooling and lubrication conditions.

Welcome contact us and OEM orders to us ! we will be your best partner in China !

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23