PVC Crust Foam Board Production Machine Line with Good Price

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

WPC Board Machine Line Conical Double Screw Extruder WPC Door Board Making Machine 1220mm WPC Foaming Door Making Machinery WPC PVC Door Board Extrusion Line WPC PVC Foamed Plates Extrusion Machine 450kg/Hr Transport Package as The Requests Specification CE, BV, SGS ISO2008 Trademark WEIER Origin Qingdao, China HS Code 84772090 Production Capacity 10 Sets/MonthProduct Description

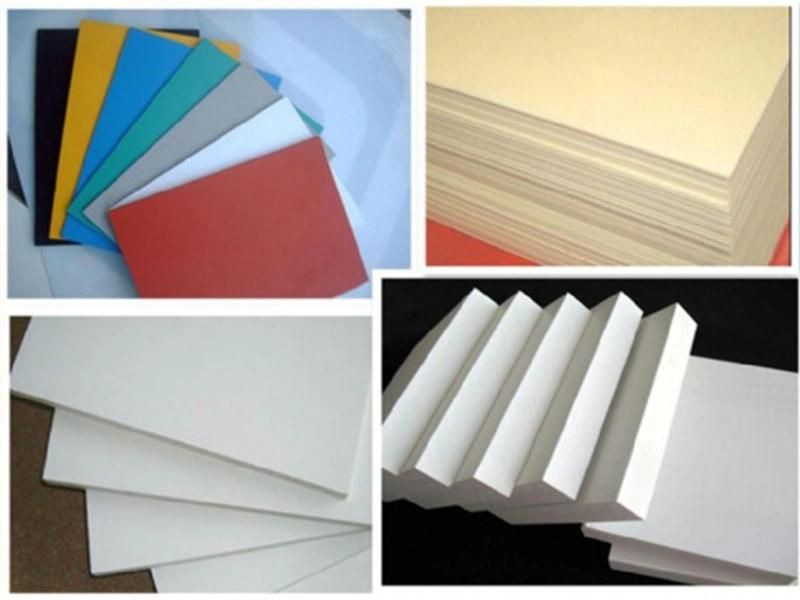

PVC Crust Foam Board Production Machine Line With Good PriceWEIER series of wide plastic door sheet production line mainly used: PVC + wood POWDER. Production overall door, construction and other wood-plastic plate Templates before the extrusion.

The line I use the original wood-plastic technology companies and formula. Plates can be based on different sections, according to the different uses of sheet metal, product design different proportions.

Selection of different specifications for the wood-plastic twin-screw extruder, and wood-plastic for single screw extruder, and the corresponding vacuum stereotypes targeting Taiwan, traction machines,

Horizontal cutting machine, expected over platforms such as auxiliary equipment.

Replacement of a different mold can produce different specifications of the plastic sheet. Traction for the company I used a unique technology, steady work, good reliability, great traction.

Increase the use of special vacuum stereotypes swirl cooling system, to facilitate cooling stereotypes, to meet the wide wood-plastic plate to the needs of the production features.

Cutting sheet metal device with the horizontal speed traction to keep pace, design reasonable, stable operation, can automatically

Main Technical Parameters

Model | Unit | SJSZ80/156 | SJSZ92/188 | SJSZ80/156, SJ65/132 |

Product width | mm | 915/1220 | 1220/1560 | 1560-2050 |

Product thickness | mm | 3-20 | 5-30 | 3-20 |

Max. extrusion capacity | Kg/h | 350 | 500 | 600 |

Power of extruder | KW | 75 | 110 |

75+37

|

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23