Bugles Snack Making Machine Extruded Fried Snack Food Corn Bugles Chips Making Machine

Shandong Longxing Plastic Film Technology Co., Ltd. / 2022-07-05

- After-sales Service:Provided

- Warranty:12 Months

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:DH65 DH70 DH75 DH85 DH95

- Application:Popcorn, Chips, Fried Snack

- Customized:Customized

- Equipment Name:Bugle Chips Snack Process Line

- Frequency Converter:Delta Brand

- Machine Material:Stainless Steel

- Product Formula:Seller Provide Formula

- Warranty Period:12 Months

- Applicable Industry:Food Processing Machine

- After Sales Service:Seller Send Engineer for Installation and Training

- Spare Parts:Provide by Seller

- Delivery:Arrange by Seller

- Certificate:SGS,CE

- Automatic:Fully Automatic

- Key Words:Fired Chips Snack Process Line

- Usage:Bugle Chips Machinery

- Voltage:Customer Settings

- Company Type:Real Factory

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Trademark:Loyal

- Origin:Jinan, Shandong

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

=== Description ===

Basic Info.

Model NO. DH65 DH70 DH75 DH85 DH95 Application Popcorn, Chips, Fried Snack Customized Customized Equipment Name Bugle Chips Snack Process Line Frequency Converter Delta Brand Machine Material Stainless Steel Product Formula Seller Provide Formula Warranty Period 12 Months Applicable Industry Food Processing Machine After Sales Service Seller Send Engineer for Installation and Training Spare Parts Provide by Seller Delivery Arrange by Seller Certificate SGS,CE Automatic Fully Automatic Key Words Fired Chips Snack Process Line Usage Bugle Chips Machinery Voltage Customer Settings Company Type Real Factory Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Trademark Loyal Origin Jinan, Shandong HS Code 8438800000 Production Capacity 5000 Sets/YearProduct Description

Bugles snack making machine extruded fried snack food corn bugles chips making machineFried Sala/Bugles snack processling line

BRIEF INTRODUCTION OF Fried Sala/Bugles snack processling line:

This line achieves mechanized process for traditional handmade wheat food. It not only continues crispy and non-greasy taste, but realizes the infinite innovation of raw material. Only twin screw extruder can accomplish the process of mixing, cooking, puffing, shaping etc. If equip with sala cutting machine, frying machine, we can produce sala chips, crust and other 2D fried snacks food. The fried bugle chips machine equips with pattern processing machine, compound shaping machine, frying machine, we can produce bugles, pillow, goldfish and other 3D fried snacks food.

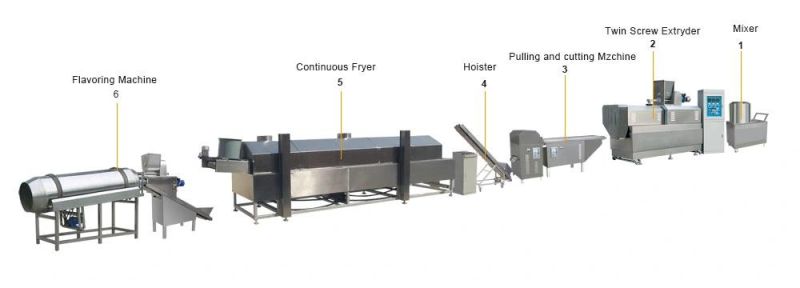

FLOW CHART OF FRIED BUGLE CHIPS PRODUCTION LINE:

Mixer--Screw Conveyor--Twin Screw Extruder--Pulling And Cutting Machine--Continuous Fryer--Deoiling Machine--Flavoring Machine

Fried Sala/Bugles snack processling line uses wheat flour as main material which are extruded, punched into triangle, fish shapes, and then fried and flavored. Such snacks with crispy taste, rich nutrition and digestible structure are very popular with many people all over the world. And most important, the waste punching chip can be reused after grinded into powder, which can greatly reduce the production cost.

| Machine Name | Function |

| Mixer | Mix The Material, Make Full Mix |

| Screw Conveyor | Conveying The Material Into The Extruder |

| Twin Screw Extruder | Extruding & Puffing |

| Pulling and Cutting Machine | Cut Off The Products |

| Continuous Fryer | Fryed The Product |

| Deoiling Machine | Make The Products Deoiled |

| Flavoring Machine | Mix The Seasoning With Products |

TECHNICAL REFERENCE PARAMETER OF FRIES BUGLE SNACK MACHINE:

| Model | Installed capacity | Power | Output capacity | Size (L*W*H) |

| DH65 | 88KW | 65KW | 150-200kg/h | 18000x2000x4000mm |

| DH70 | 126KW | 82KW | 200-250kg/h | 22000x2000x4000mm |

| DH70L | 126KW | 82KW | 250-350kg/h | 26000x2000x4000mm |

Features of Fried Sala/Bugles snack processling line:

1. Raw materials: rice flour, corn flour, flour or their mixtures are the main raw materials.

2. Product: This production line can produce rice crackers, salad bars, salad chips, crispy corners, crispy corners, etc. by adjusting the die of the extruder.

3. Output: 120-150kg/h, 180kg/h, 200-250kg/h, 200-250kg/h, 500kg/h, 800-1000kg/h

4. Process: powder mixer → twin screw extruder → traction cutting machine → hoist → continuous fryer → seasoning machine

5. Voltage: three-phase: 380V/50Hz, single-phase: 220V/50Hz, we can also customize according to the local voltage of the country where the customer is located

6. Machine material: all machines are made of stainless steel, and the screws are made of alloy steel. The production line has a reasonable design and a high degree of automation.

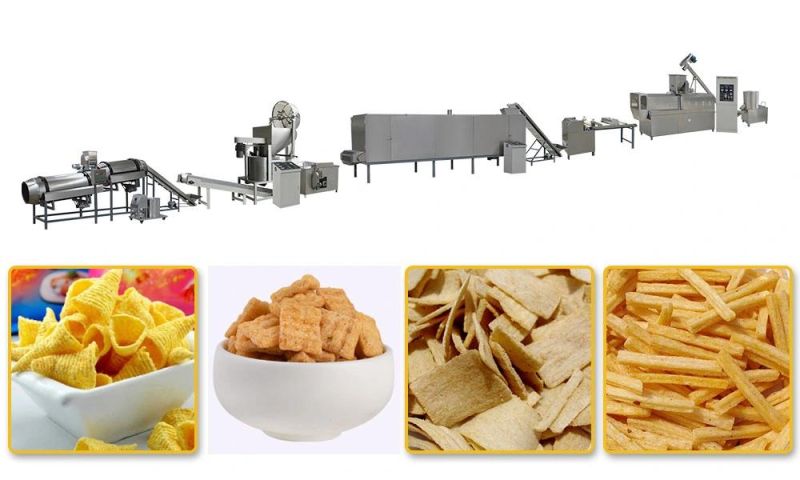

SAMPLE PICTURES OF FRIED BUGLE CHIPS:

The raw materials can be rice powder, corn powder, wheat flour individually or their mixture. Only by changing the moulds, shaping or cutting machine, the shapes can be various, like sticks, square sheet rib chips, diamond chips, wavy chips, pillow shapes and bugles etc. The taste is savory and not greasy.

EQUIPMENT MATERIAL OF FRIES BUGLE SNACK MACHINE:

1. All Fried bugle chips production line are made of food grade stainless steel

2. Screw: Alloy steel (38CrMoAl)

3. HRC hardness is around 60 --- 62, with good self-cleaning ability, no need to unload or clean the barrel and screw when baking or changing materials.

4. The extrusion cylinder is made of carbon steel, made of 45 steel, stainless steel coating.

5. The gearbox has an automatic lubrication function, which can extend the life of the gear.

6. The cutter is fixed on the die head base and rotates through the V-belt drive.

OUR SERVICE & TURNKEY SOLUTION

1. ) Consultation service before, during, and after sales;

2. ) Project planning and design service;

3. ) Debugging of equipment until everything is functional;

4. ) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5. ) Training of equipment maintenance and operating personally;

6. ) New production techniques and formulas;

7. ) Provide 1 year complete warranty and life-time maintenance service.

COMPANY INTRODUCTION

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, puffed and fried bugle snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, cornflakes prodcution line, instant noodle machinery, pasta machinery, etc. food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

We have sold our fried bugle snack plant to below countries:

Asia {Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North & South America { Canada, Brazil, Bolivia }

Oceania { New Zealand }

ENGINEERS AVAILABLE TO SERVICE MACHINERY OVERSEAS

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warranty and lifetime maintenance service.

OUR HONOR

Loyal brand was famous well-known at global and domestic market, and it is sold to more than 50 countries and regions, with ISO system, SGS certificate, 10 CE certificates, and 25 patents on Technology Patent, since then, we keep forward on the quality control, new technology developing and the better customer service.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23