Parallel Twin Screw Hot-Air Die-Face Plastic Machine

Hubei St. Bairui Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TSK75B Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Tsk35 Tsk95 Transport Package Wood Pallet and PE Film Specification ISO9001, CE Trademark BEIER MACHINERY Origin China HS Code 84772090 Production Capacity 100sets/YearProduct Description

Tsk Series Parallel Twin-Screw ExtruderTSK Parallel twin-screw extruder is a kind of high-efficiency compounding and extruding equipment.

The screw & barrel adopt building block type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics to get the best work condition and max function.

Because it has good mixing, separating, dewatering and self-cleaning functions to avoid the materials wrapping the axle, caking in the extruding process. With the rotation of the screw, the surface of the materials continuously change, helps the volatile matter dewater, treat, and etc.

Machine Design

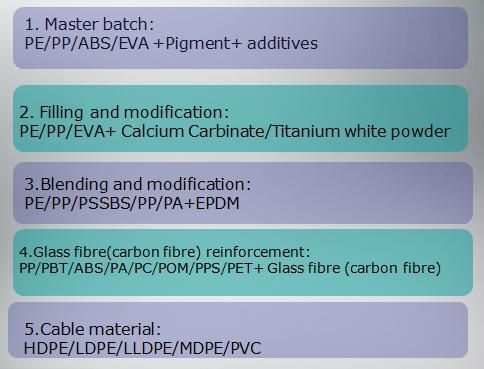

Usages of TSK Series Parallel Twin Screw Extruder

Compounding&Granulating Methods

Hot-air Die-face Pelletizing Line:

Technical Parameter

| Model | TSK-75 |

| Screw diameter (mm) | 71.2 |

| L/D | 32-52 |

| Main motor (KW) | 132-160 |

| Max screw speed (rpm) | 600 |

| Capacity (kg/h) | 400-550 |

Technical Parameter

| Model | Pipe range(mm) | Extruder model | Extruder Motor power(kw) | Max.output(kg/h) |

| BRD-63 | Φ20-63 | BRD60/38 | 90 | 450 |

| BRD-110 | Φ20-110 | BRD60/38 | 110 | 500 |

| BRD-160 | Φ40-160 | BRD60/38 | 110 | 500 |

| BRD-250 | Φ50-250 | BRD75/38 | 160 | 680 |

| BRD-400 | Φ160-400 | BRD90/38 | 250 | 1000 |

| BRD-630 | Φ280-630 | BRD90/38 | 280 | 1100 |

| BRD-800 | Φ315-800 | BRD120/38 | 315 | 1300 |

| BRD-1200 | Φ500-1200 | BRD120/38 | 355 | 1400 |

| BRD-1600 | Φ1000-1600 | BRD90/38&BRD90/38 | 250+250 | 2000 |

| BRD-2000 | Φ1000-2000 | BRD90/38&BRD90/38 | 280+280 | 2200 |

Our certification

About Jiangsu Beier Machinery:

Jiangsu Beier Machinery Co., Ltd is specialized on plastic extrusion and recycling machinery manufacturing.

We have top-ranking Research and Development technology system and rich experienced technician team.

Our vision is to offer you the best and the most appropriate plastic extrusion and recycling solution, to offer you the most reliable technically and commercial service support.

Pre-Sale and After-Sale Service:

1. Provide all the machines for the complete production according to customer's requirements.

2. Provide complete service for factory layout and other information to help customer to build the factory.

3. Provide the raw material to the customer if need.

4. Provide good service for machine installation and training, until the customers can run the machines and make stable production.

5. Provide after-sell service for all the life, except one year quality guarantee,

6. Provide good quality, good price and good service to customer. We are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23