Aerator for Batter, Cream

Hubei Hawking Packaging Material Co., Ltd. / 2022-07-05

- Usage:Cake

- Power Source:Electric

- Timing Device:With Timing Device

- Type:Oven

- Voltage:380V

- Customized:Customized

=== Base Info ===

- Model NO.:DR-A500

- Capacity:500-1200kgs,Hour

- Transport Package:Safe Packing

- Specification:CE

- Trademark:D&R

- Origin:Ningbo of China

- HS Code:843810001

- Production Capacity:5sets,Year

=== Description ===

Basic Info.

Model NO. DR-A500 Capacity 500-1200kgs/Hour Transport Package Safe Packing Specification CE Trademark D&R Origin Ningbo of China HS Code 843810001 Production Capacity 5sets/YearProduct Description

Aerator for Batter, CreamStandard version made of stainless steel aisi 304.

Max. production: 500kgs/h.

Composed by:

1.1 Storage tank (capacity 300L)

1.2. Turbo emulsifier

Technical features:

Structure made of stainless steel AISI 304 completed with movable panels.

Storage tank made of stainless steel AISI 304, jacketed and predisposed for the circulation of the liquids for the heat exchange.

Product agitator to maintain the product homogeneously.

Head made of stainless steel AISI 304, with a double wall for the circulation of the heat exchange liquids. Motorization at 7.5 kW controlled by a frequency converter.

• Volumetric pump made of stainless steel AISI 304 with motorization, controlled by frequency converter studied for the head cleaning.

Product filter at the head entrance.

Pneumatically controlled counter pressure device.

Discharge pipe made of stainless steel DN50 equipped with n° 1 valve for the product sampling and a butterfly manual valve.

Pneumatic board to be connected to the compressed air line and equipped with purifier filters at active carbons for the air injection in the head and fluxmeter with manual adjustment of the capacity.

Electric board lodged in a separate cabinet made of MS and equipped with Siemens PLC and WeinviewTouch Screen control panel.

Detailed Images:

Purpose And Characteristic:

The products made by our machinery allow you to achieve a better texture, a highly improved mouth-feeling sensation, fewer calories and cost savings. We offer you the opportunity through our technology and our food technologists to improve and develop your products. The entire production line with food sanitary standard, and there is no hand touch on the products till the end of packing.

Our Advantages:

1.D&R Industries With Many Years Experience

2.High Technology team

3.Giving The Whole Project Solution

4.Consulting For Candies, Gummy, Chocolate And Its Packing

5. Always Giving The Economic Machine

6.Better Quality, Better Service After Sales For All Of The Customer

Company Introduction:

TOTAL SOLUTION ,TOTAL CARE

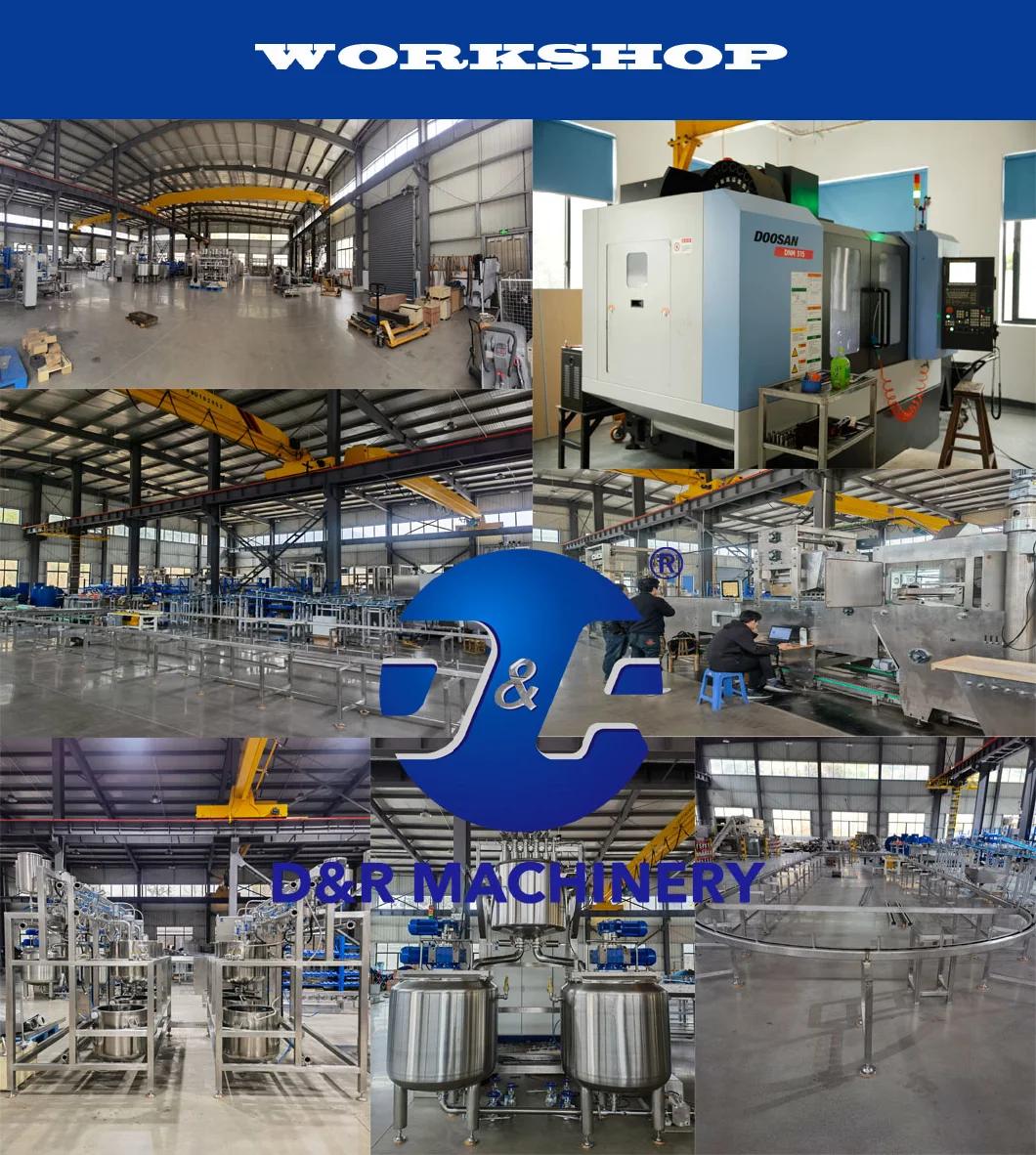

D&R Machinery are professional confectionery machine manufacturers with over 10 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23