PVC Upper Rotate Film Blowing Machine Shanghai China

Hangzhou Future Hardware Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ65 Automation Non-Automatic Computerized Non-Computerized Machine Weight 4T Certification CE, ISO9001:2008 Transport Package Warp Film Packing Trademark beiyangsj Origin Shanghai HS Code 84773010 Production Capacity 80kg/HProduct Description

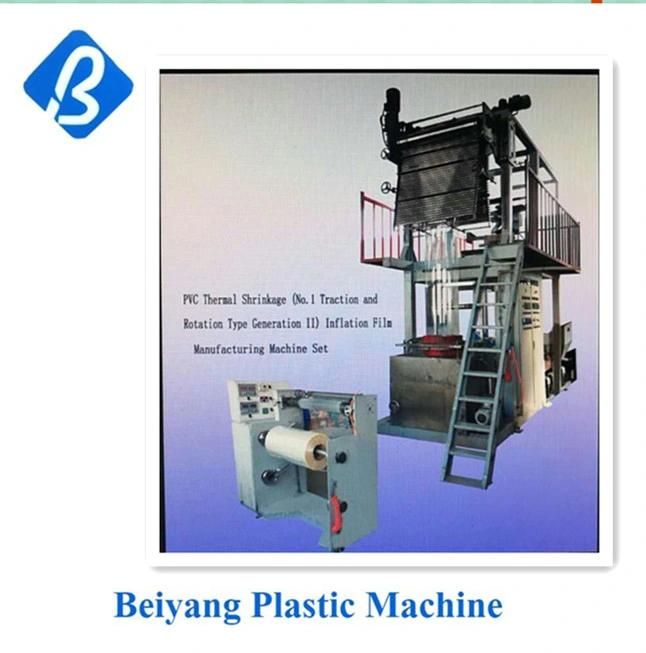

PVC Thermal Shrinkage (No.1 Traction and Rotation Type Generation II) Inflation Film Manufacturing Machine Set

This machine set is an updating product for manufacturing PVC thermal shrinkage (printing grade) inflation film equipment. The target of successfully researching and manufacturing is that product quality reaches or exceeds the international standard, i.e.: thickness uniformity is less than 5 to 6 μm; film straightness is less than 2 to 4mm/4M; rib exposure does not occur during natural shrinkage, and the film surface maintains smooth.

180~320.ºC displacement rotation.1 traction rotation refers that raw film blown by a mould is rotated and deflected at 180-320 degrees after entering into No.1 traction roller. By adopting DD-LTD brushless servo deviation-correcting device, raw film is transmitted to a water tank to be subjected to secondary inflation. During this process, water temperature control has a significant effect on thickness uniformity, and we adopt high-precision intelligent digit power regulator (SCR pulse control), the mutual deviation of water temperature is 80±0.1 DEG C, and it also has the energy-saving effect.

This machine is a technically patented product in 2016, at present it is put into volume production, welcome the domestic and overseas friends to visit and purchase.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23