Pearldrill Rotary Water Well Drilling Rig 300 Meters Deep Hole Big Power Diesel Hydraulic Water Well Drilling Rig Irrigation Drilling Rig

Hangzhou Fuyang Huibo Hansway (BOWAY) Trading Co., Ltd. / 2022-06-23

=== Base Info ===

=== Description ===

Water well drill rig

Instruction Manual for New Hydraulic Drilling Rig

Thank you for choosing to use our hydraulic drilling rigs, and I hope you can give us better feedback.

. Installation and debugging

1. First check whether the drilling rig equipment and tools are in good condition.

2. First add 30-40 catties of hydraulic oil, gasoline engine should add 95 gasoline, gasoline engine oil should be replaced in time.

3. When lifting, do not lift the drilling rig too high, and it is forbidden to stand or work below.

4. Please read the instruction manual and perform the actual drilling work after the operation is proficient.

. Matters needing attention

1. During the actual drilling, first find the position of the wellhead, and level the position where the machine is placed to avoid shaking.

2 Stand up the folded part of the drilling rig and fasten the fixing point screws.

3. Connect one end of the high-pressure water pipe to the water inlet of the main engine, and the other end to the water outlet of the pump, and tighten it with iron wire.

4. Dig a reservoir next to the well drilling machine, put the water inlet of the pump directly in the pool, and use circulating water when working.

5. When drilling, the safety cover is opened, the drill bit and the drill pipe are connected to the main engine, and the wire rope is kept in a slack state. No matter whether each rod is drilled to the bottom, the main engine part falls to the bottom. When changing the rod, lift it up again and close the safety cover. Well, let the joint head be 5 cm above the safety cover, and rewind the wire at this position.

6. When drilling down two to three drill pipes, make sure whether the water pump is blocked by mud, and keep the water pump running smoothly, so as not to block the drill bit or the mud can not rush up, causing difficulty in lifting the rod.

7. During drilling, if it is necessary to rewind the wire, first stop the reversing switch to the middle position, and wait until the speed of the drilling rig stops before rewinding the wire.

8. In the process of transportation, it can be installed separately, be careful not to damage the parts, and not to be exposed to rain or water.

. Mastering the water layer

When the drilling rig is about to drill to the required depth, it should be noted that the water is washed with large grains of sand or mud, like water-white mud eggs, irregularly rounded and somewhat smooth, all of which are water layers. so far.

.Equipment maintenance

Whether the gear box of the drilling rig and the reduction box of the lifting rod are short of oil, every time the well is drilled and completed, the water pump, drill bit and joint head should be flushed, and the joint head, V-belt, wire rope, etc. should be checked frequently for damage or replaced in time. We are not responsible for any accident caused by improper operation, please use it carefully. Please contact us if you have any details.

Major equipment

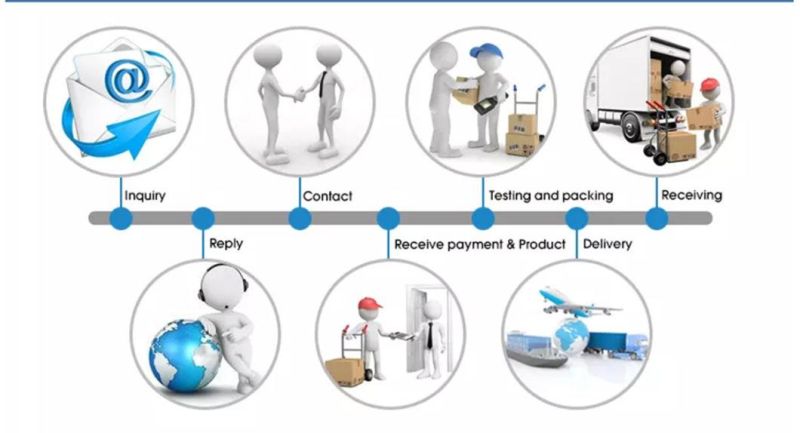

What we offer:

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4)Our well drilling rig sales in China first, China's largest well drilling rig manufacturer

5) Smooth communication

-COMPANY BRIEF-

We provide high-quality and complete drilling equipment including drilling rigs, drilling tools, mud pumps, DTH drilling tools, rock drilling tools, etc. They are widely used in water wells, farmland irrigation, geological exploration, small pile holes, geothermal, rope coring, Mining etc. Our products are the products of choice for drilling engineers in many countries due to their precise design and efficient drilling in use.Main product

Application

Borehole drilling, Civil Infrastructure, civil engineering, and infrastructure, for rock core drilling, Soil Testing and sampling, geophysical survey companies, Pile foundation drilling, bridge drilling, wind power generation, large-mouth engineering drilling, oil field, metallurgy, mining, geological mineral exploration, water conservancy and hydropower construction, coal mine, mine tunnel drilling, grouting reinforcement engineering, highway, subway, high-speed rail, concrete core sampling, etc, Coring exploration, drilling.

Workshop

Why we achive today′s achievements is because we are supported and assisted by a highly experienced team of designers and engineers that enable us to complete all the assigned projects successfully as per the specified requirement from our clients. Speedmade Industries Co., Ltd will continue committing to provide low cost Rock Drills, Drilling tools, well drilling rigs, high efficiency drilling tools, energy saving and environmental product for domestic and international clients.

-WHY CHOOSE US-

--The first-class engineers of tricone bits and PDC bits--Advanced technology and Equipment, International standard.

--R&D center for rock drilling tools, high precision CNC machines, SGS&ISO Certified.

--10+ Years & 40+ Countries of service experience.

--Optimized solutions for the various requirements.

DIY customization: please provide your rock formation information or detailed size drawings.

Free samples: some samples can be provided free of charge.

Payment:T/T L/C,D/A,D/P,Western Union,MoneyGram.

| Packaging |

| Wood Box Fumigation Tray if necessary Other special package can be applied according to customer's need |

| Delivery |

| Prepared to deliver within 1 week, if in stock Depends on order quantity, when out of stock Transportation:By sea or air |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23