75W 90W 100W 130W 150W Reci W1 Efr Reci CO2 Gas Laser Tube for Laser Cutting Machine

Bestpoly (Xiamen) Plastic Co., Ltd / 2022-06-23

- Customized:Non-Customized

- Standard Component:Standard Component

- Type:Glass CO2 Laser Tube

- Transport Package:Carton

- Specification:5Kgs

- Trademark:RECI

=== Base Info ===

- Model NO.:W1

- Origin:China

- HS Code:9013200099

- Production Capacity:10000 Sets Per Month

=== Description ===

Basic Info.

Model NO. W1 Origin China HS Code 9013200099 Production Capacity 10000 Sets Per MonthProduct Description

1. Feature:

Reci upgrades and brings CO2 glass laser tube to 3.0 generation. Through the last ten years of development, the CO2 glass laser tube now develops to the third generation. The third generation of laser tube cancels the adjusting screws at both tube ends. Instead, the metal parts are made by high-precise CNC machine. New firing technology is used to join metal parts and glass parts together directly. This new technology makes the high stability in W series laser tubes.

2. Product characteristics:

2.1 Beam quality: >95% TEM00 mode

2.2 Optical resonator advantage: enhance power

2.3 Advanced radioactive materials coated lenses

2.4 Alternative technique: metal-glass sintering

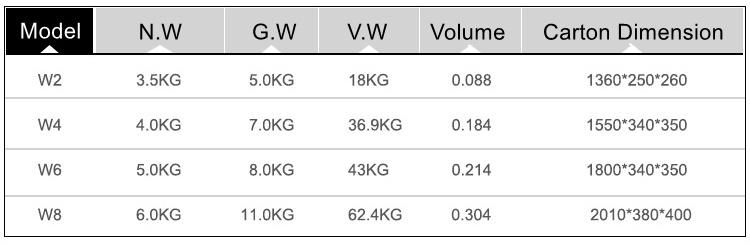

3. Technical Parmeters

4. Cleaning Tips: When cleaning the window of carbon dioxide laser tube, please do not use cotton swabs or other wipes as they will significantly affect out power.

The following methods are provided for cleaning the window:

4.1 When the lens is stained, turn off the laser tube.

4.2 Use an air dust blower to blow away dust and dirt on the lens.

4.3 Use a syringe to spray ethanol on the lens.

4.4 After the ethanol evaporates, turn the laser tube back on.

4.5 If the above method do not work effectively, professionals are required, who will use a cotton swab dipped in ethanol to clean the lens in a rotating fashion away from the center, outwards to the edge.

5. Special Notice:

5.1 Do not use acetone to clean the glass.

5.2 Do not move the two fastening screws on both ends of laser tube. Otherwise, the output power will decrease, and the laser tube will be scraped.

5.3 When testing the light spot on organic glass, please keep the organic glass 300mm away from the window.

6. Safety:

At the CO2 glass laser device generates invisible light, please wear eye protection gear when operating. A safety sign for high voltage is marked on the positive pole.

7. Storage and Transportation Requirement:

When storing and transporting the co2 laser tube, please drain the cooling liquid and cover the tubes ends with dustproof plastic bags. For storage, the required environmental temperature is 2-40 ºC and the humidity range from 10-60%.

Adhesive tapes and sponges should be used to fix the laser tubes and prevent sliding during transport. A 70mm sponge should be use at the end of the window, and a 50mm sponge should be at the end of the reflecting mirror fully.

8. Related Laser Machine Parts

8.1 Power Supply

8.2 Focus Lens

8.3 Reflective Mirrors

9. CCILASER Factory

CCILASER is headquartered in Jinan City, China. It is a world-renowned laser equipment company and a high tech enterprises integrating R&D, production and sales.

We are adhering to the tenet of "Quality first, customer first" and continues to grow. Main products include fiber laser cutting machine, plasma cutting machine, laser marking machine, laser engraving machine, laser welding machine and laser cleaning machine and etc.

Our company has passed ISO and CE international quality management system certificates, and has obtained FDA certification for the US market. We have our independent export rights.Machines are exported to more than 50 countries and regions.

Wish cooperating with you to create a better future!

10. CCILASER Staff Style and Exhibition Show

11. FAQ

A. Question: What kind of our company is CCILASER?

Re: CCI is laser cutting machines, laser welding machines, laser marking machines manufacturing expert since year 2002.

B. Question: How is co2 laser cutting machine laser tube guarantee?

Re: b1.co2 laser cutting machine laser tube warrenty period is 12 months after BL time;

b2.12 hours technical support feedback;

b3. Own machining factory, which can control the spare parts quality at high quality;

b4. Own accessories warehouse and user can enjoy the agent price.

C.Question: How is delivery time?

Re: We can delivery the machines within 7 days if we have the machines in stock.

The common machine fabricating time is 15-25 days and CNC machine fabricating time is about 25-50 days.If you have customized products, the delivery time will be given after confirmation.

D. Question: How is payment?

Re: 50% of amount as deposit and the balance should be paid by T/T or LC at sight before seller delivery the machines to loading port.

E.Question: How is our package?

Re: Wooden Pallet/ Wooden Case. In order to ensure high quality products precision, the perfect package is necessary.

F. Question: Why is price higher than other supplier?

Re: f1. We have our own machining factory and the high quality technical quality is our aim;

f2. All the electric parts and pneumatic parts are high quality. Most of them are imported from european and american market;

f3. Most of fabricating worker has more than 10 years working time. Their fabricating work is professional and salary is higher;

f4. Our warrenty period is 12 months after BL time. It can support the new comer client going well in the beginning time.

Customer Care

To be continued..

To be continued..

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23