Stripping Machine

Zhejiang Huawei Machinery Co., Ltd. / 2022-06-27

- Blanking Head Type:Twin Head

- Customization:Supported

- Transport Package:Null , Wooden Box

- Specification:3500 x 1800 x 1900mm

- Trademark:Huawei

- Origin:Wenzhou

=== Base Info ===

- Model NO.:MSCB 680 , 920 , 1080

- Production Capacity:100+ Sets , Year

=== Description ===

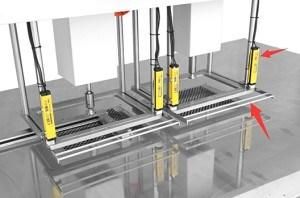

Excellent hydraulic system

Double safe protection

Our hydraulic system have multistage of speed,

the oil cylinder can goes down slowing when you

press the inching bottom, more convenient for

job change over.

Protection 1 : Mechanical safe protection

Protection 2: High density safe light curtain

Material Movement System

Arrange Pins to the Proper Shape

After the blanking material has been picked up, the

sheets automatically slide into place, and blanking

is performed efficiently.

By simply arranging the pins, the blanking machine

can blank a variety of product shapes and sizes.

Precise arranging pins loader

Mature manufacturing technique

- The high density stripping pin loader is made by

CNC processing center.

- Reasonable and compact design makes the

stripping pin changing jobs are easy and fast.

- High precision and no need to change blanking

tools

The whole machine parts and accessories are

made by fully automatic CNC processing center.

Sealed and compact structure, dust proof.

Longer machine service life.

Solid structure and bear high pressure

Double servo, Ball-Screw and LM Rail Drive

Systems

The new generation of blanking machine adopts a

double cross beam structure. This structure is

much more solid and it won't get crushed due to

high pressure (especially for big models)

The ball screw is driven by double servo to ensure the high

product precision

By using the Ball-Screw and LM Rail Drive Systems,

blanking precision with smooth and quiet operation is

realized.

pre:

Auto Blank Separatornext:

Waste Stripping MachineNew product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23