Yc-Lok Union Elbow Equal Male Tube Fittings Adapters

Billion Plastic Manufacturing Co., Ltd. Jiangmen / 2022-06-27

- Certification:IATF 16949

- Pressure:High Pressure

- Work Temperature:High Temperature

- Thread Type:Internal Thread

- Installation:Flared Type

- Material:Stainless Steel

=== Base Info ===

- Model NO.:755HF

- Type:Cut Through

- Application:Indurstry,Hydraulics

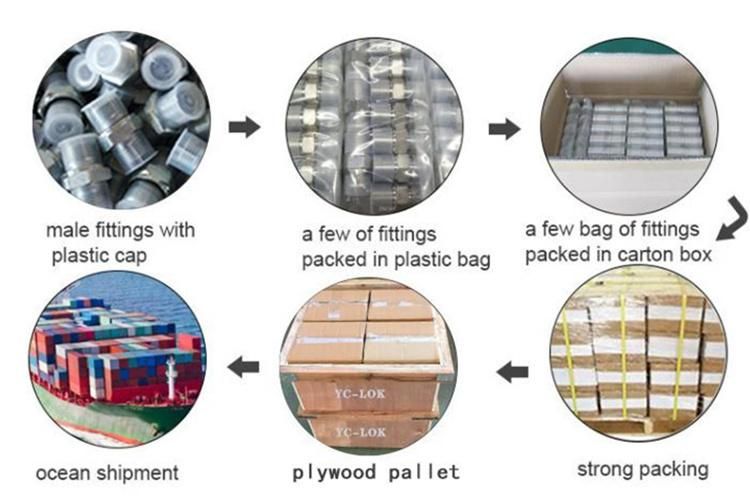

- Transport Package:Wooden Box with Plastic Bag

- Specification:20*30*10

- Trademark:YC-LOK

- Origin:China

- HS Code:7370290000

- Production Capacity:10000PCS,Week

=== Description ===

Basic Info.

Model NO. 755HF Type Cut Through Application Indurstry/Hydraulics Transport Package Wooden Box with Plastic Bag Specification 20*30*10 Trademark YC-LOK Origin China HS Code 7370290000 Production Capacity 10000PCS/WeekProduct Description

TUBING DATA FOR 37° FLARE

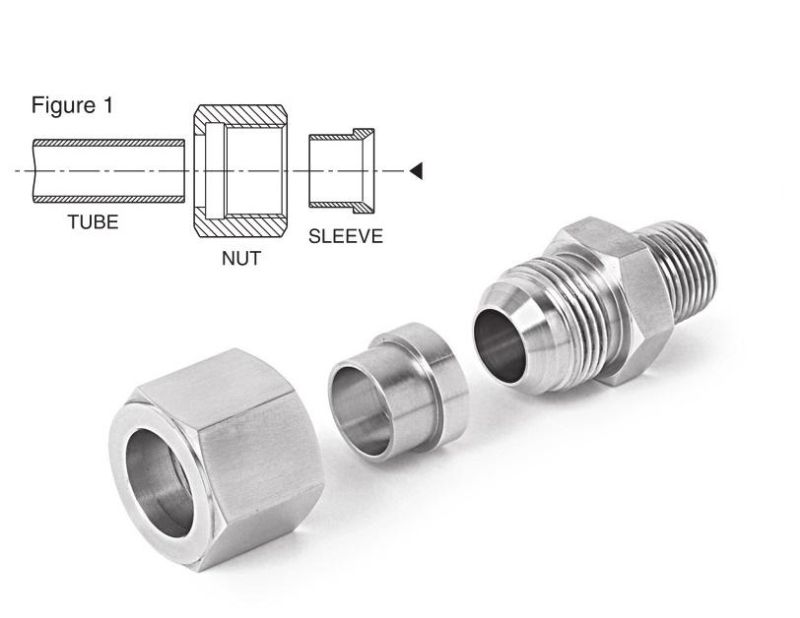

THREE-PIECE TUBE ASSEMBLY

In order to ensure maximum fitting reliability and performance, please take great care when selecting the tube for each application.Tubing should be fully annealed, seamless and drawn, suitable for bending and flaring, according to standard ASTM-269, A.I.S.I. 316 or 304.

| 1.Packaging Details: | 1. Wooden box 2. Carton 3. As your request. |

| 2.Delivery Detail: | Shipped within 15~30 days after payment |

| 3.Logo: | Any logo is available |

| 4.MOQ: | 100 pcs |

| 5.Samples: | Free |

| 6.OEM Accepted | Yes |

| 7.Production Capacity: | 10,000pcs Per week |

| 8.Payment Term: | L/C,T/T,D/P,D/A,PAYPAL,WESTERN UNION,MONEY GRAM |

ASSEMBLY INSTRUCTIONS

1. Cut the tube to the proper length.

2. Slide the nut and sleeve onto the tube.

3. With a special flaring tool, form the flare to 37° dimension according to SAE STD. J533.

4. Screw the nut onto the body until finger tight.

5. From this position, tighten the nut with a wrench 1/4" turn in order to make a leakproof metal-to-metal connection.

QUALITY

Lengths of finished tubing should be reasonably straight and have smooth ends, free from burrs. Tubing should be free from scale and injurious defects, and it should have a workmanlike finish.

Surface imperfections such as handling marks, die marks, or shallow pits will not be considered.

injurious defects provided the imperfections are within the tolerances specified for diameter and wall thickness. The removal of such imperfections is not required. (Quality SAE J524).

Quality Control (control plan)

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

CONTACT US IF ANY PRODUCTS CAN MEET YOUR DEMADN!

FAQ:

Q1: How long is your delivery time?

A:Delivery time is depends on the total quantity of order. Normally, sample can be delivered within 15 days.

Q2: Do you provide samples? Is it free or extra?

A:Yes, we could offer sample for free, and we can pay for the model as well, but the clients has to pay for the shipping cost.

Q3: What is the MOQ of your products?

A:It depends on the category or order.

Q4: Where is your factory?

A:Our factory located in Jiangsu province, close to Shanghai port.

Q5:What does your company need to submit a quotation?

A:Drawing or Sample, together with relevant information, such as Quantity, Weight, Material. Or we can send for reference to confirm.

Q6:What we do not have a drawing?

A:We can duplicate your sample and make drawing for your confirmation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23