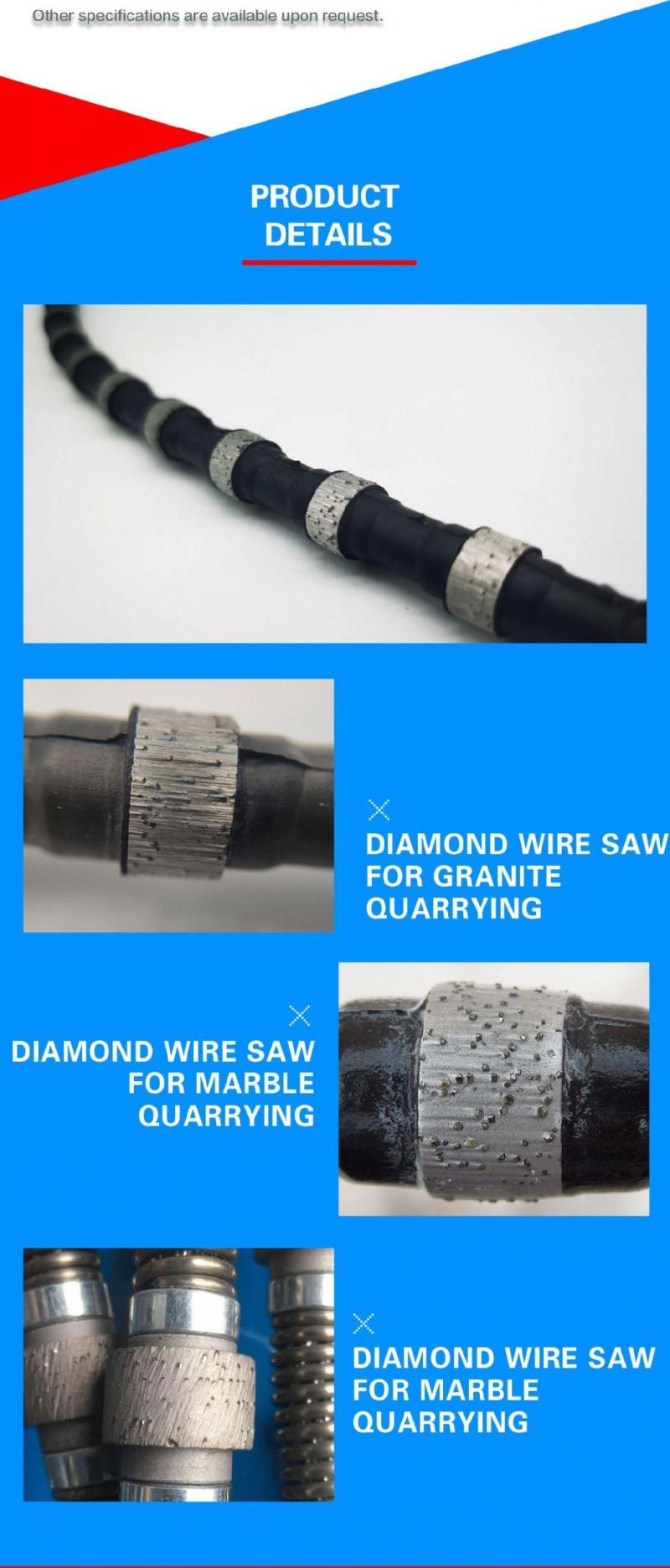

Marble Diamond Wire Saw for Quarry Wire Rope Rubber Spring Wire Saw

Qingdao Zhoushi Plastic Packaging Co., Ltd. / 2022-06-27

- Application:Marble Quarry

- Type:Rubber + Spring Coating

- MOQ:50 Meters

- Transport Package:with Linxing Loge Carton

- Specification:11.5*40

- Trademark:Linsing

=== Base Info ===

- Origin:Shangrao, China

- Production Capacity:5000meter,Week

=== Description ===

Basic Info.

Origin Shangrao, China Production Capacity 5000meter/WeekProduct Description

Diamond wire saw for marble quarry

The characteristics:1: The diamond wire quarrying technique can highly improve the quarrying efficiency, reduce the waste of mining resources,

2: It can exploit large dimension blocks. At the same time, it can be operated safely and it is good for environmental protection.

3: Independently developed the special rubber and vulcanized technique to ensure that the diamond wires can work in all sorts of bad environments.

4. The rubber and cable sticking together tightly make good bonding, and this can be more strikes during the work.

5. The vulcanized rubber easily withstands increases in temperature caused by badly controlled water spraying, which often happens in a quarry.

6. Strong flexibility can reduce the cut-in-one-side problem, and protect the cable well when it is used for small curvature radius(beginning and end of quarry cuts).

| Specification | Reinforcement | Beads number | Cutting material | Line speed | Cutting speed | Wire life |

| Dia11.5mm | Rubber | 40/m | Hard marble | 20-30m/s | 5-10 m2/h | 15-25m2/m |

| Dia 11.0mm | Rubber | 37/m | Middle hard marble | 20-35m/s | 10-15 m2/h | 20-35m2/m |

| Dia 10.5mm | Rubber | 33/m | Soft marble | 25-35m/s | 15-20 m2/h | 30-50m2/m |

| Dia 11.0mm | Spring+Plastic | 30/m | Hard marble | 20-30m/s | 5-10 m2/h | 15-25m2/m |

| Dia 11.0mm | Spring+Plastic | 30/m | Middle hard marble | 20-35m/s | 10-15 m2/h | 20-35m2/m |

| Dia 10.5mm | Spring+Plastic | 28/m | Soft marble | 25-35m/s | 15-20 m2/h | 30-50m2/m |

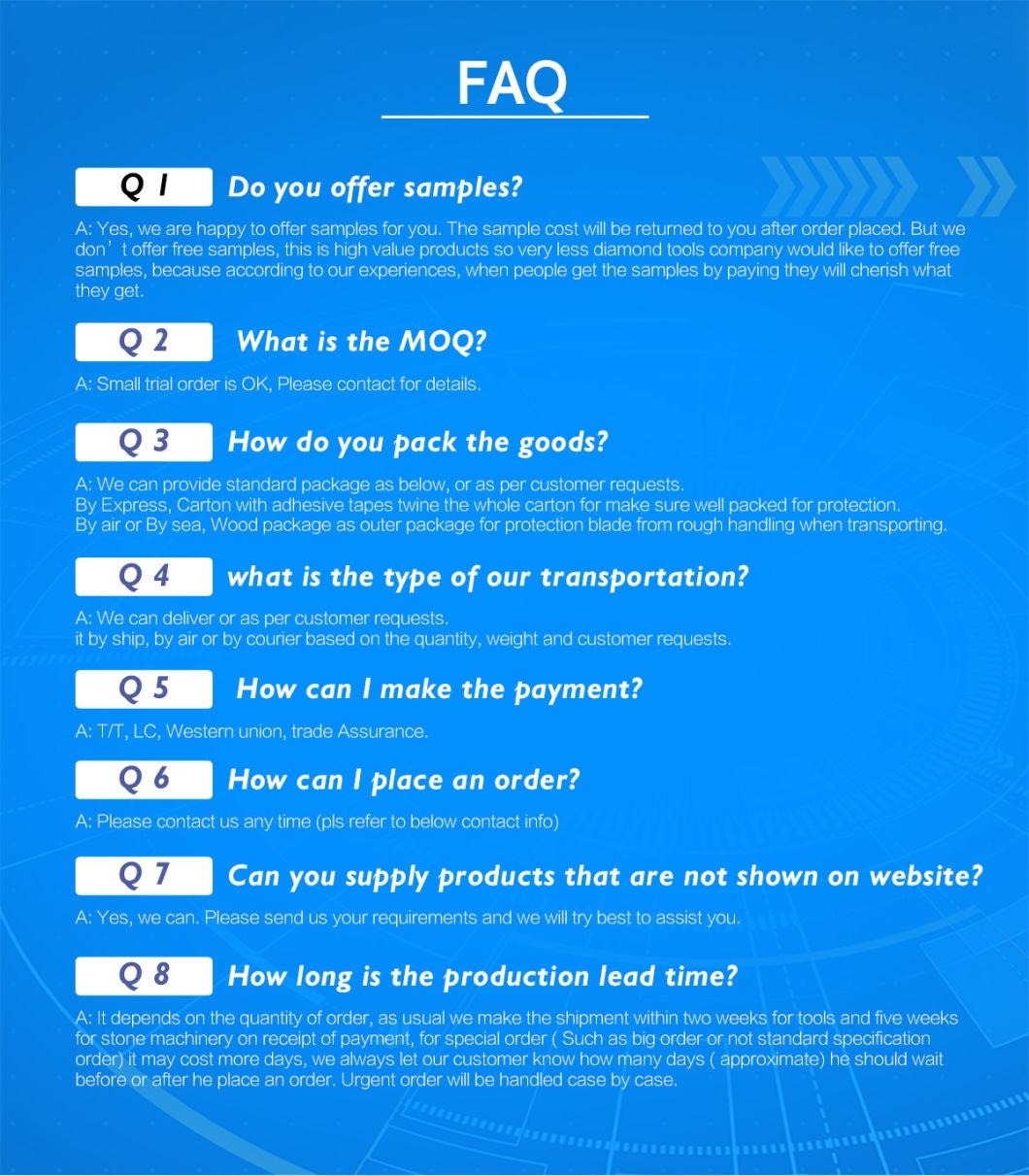

LINSING diamond wire saw features:

1. High efficiency, safe, low-noise, less-dust, and environment-friendly.2. Good cutting with the small slots.

3. Few breakage ratios at working thus sound lifetime.

4. Professional engineers, experienced workers, strict quality control system, top quality material, etc. ensure stable quality.

5. Other specifications are available upon request.

How to use diamond wire saw for mining:

Quarry&mining is a major project that requires a lot of manpower and material input. For example, roads must be built first. If there is no road near the mine, then even if the stone is extracted, there is no way to transport it out. It just needs water, electricity, no electricity, large machinery can not work, without water, the cutting process cannot be cooled, and the stone cannot be cut, and mining is impossible.

After the above basic conditions are met, there are prerequisites for mining. In general, diamond wire saw mining can be divided into four steps, namely, drilling, threading through holes, installing equipment cutting, and adjusting. The following article gives a specific introduction to quarry mining:

The first is drilling. drilling is a key preparatory work. If the hole is not well drilled, it will directly affect the penetration of the diamond wire saw and affect the service life and cutting efficiency of the wire saw. Therefore, the process of punching is particularly important. for cutting a large block, it needs to make three holes, one vertical hole, and two horizontal holes.

Secondly, the diamond wire is threaded and perforated. At present, we mostly use the manual method of threading, fixing one end of the rope with a multi-strand loop cord, passing it in from one hole, and using iron wire to lead out from the other hole. In foreign countries, there is a method of animal threading, like the mouse is tied to a wire and filled with water to allow the mouse to drill out of another hole.

Then install the wire saw machine. because the equipment is heavy, and after cutting a flat surface, the equipment needs to be re-adjusted, so it requires lifting equipment around it, which can be lifted at any time. After the equipment is installed, you can start cutting. Generally, the horizontal cutting is performed first, and then the vertical cutting is performed to prevent the wire saw from idling or jamming the beaded rope after the vertical cutting at the final stage of the horizontal cutting process. Must pay attention to the water supply during the cutting process, otherwise, the large amount of heat generated by the cutting will cause the steel wire to deform, or the rubber will age, and the spring will melt and lose the role of fixing the beads, which will shorten the life of the wire saw.

Adjustment, In the process of mining, the bending angle of the wire saw is constantly shrinking. In the last part, the bending angle of the wire saw is very large, so at this time, we must pay attention to the running state of the wire saw. If there are sparks or the sound of the wire saw cutting is too large, it is best to find a good location and add a flywheel, so as to keep the wire saw from over-bending and causing deformation, thereby shortening the service life.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23