(RVP) Spc Flooring Production Machine

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ-92/188 Customized Customized Condition New Machine Name Spc Machine Width 970 Thickness 2-6 Capacity 600-800kg/Hr Raw Material PVC Material Dimension 27m*5m*8.5m Weight 22t Power Supply 380V 3phase 50Hz or as Per Your Request Operator 2-3worker/Shift Container 2 40foot Container Transport Package Machine Covered by PE Film; Mould in Wooden Case Specification Follow Customers′ Need Trademark WEIER Origin Qingdao, China HS Code 84772090 Production Capacity 15 Units Per MonthProduct Description

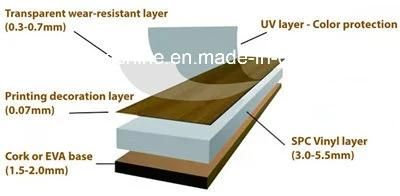

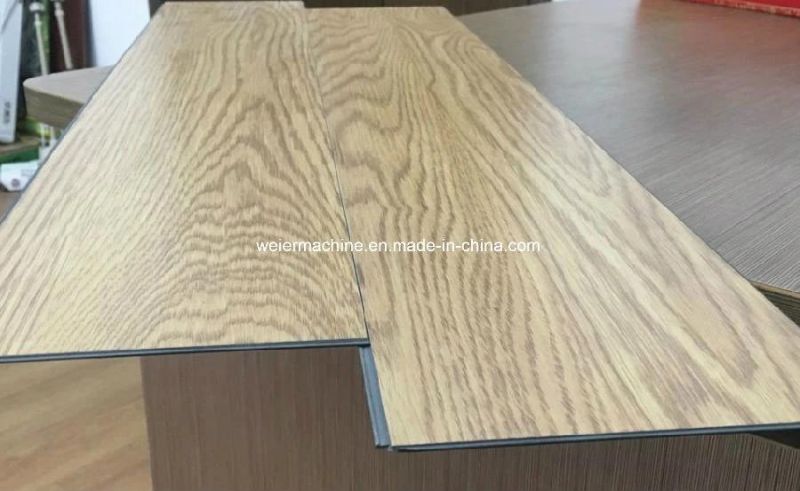

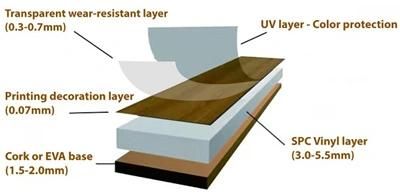

Stone Plastic Composite Spc Waterproof Flooring Mat Extrusion Making MachineSPC: stone plastic composite, European and American countries call this kind of floor RVP (rigid vinyl plank), rigid plastic floor.The click-type SPC stone plastic flooring is actively promoted and rapidly developed at home and abroad.

SPC floor feature and advantages :

SPC flooring is a new type of environmentally friendly composite material. Its advantages include the following:

- waterproof, moisture-proof. It fundamentally solves the problem that wood products can easily rot and distort after absorbing moisture in wet and multi-water environments, and can be used in an environment where traditional wood products cannot be applied;

- Anti-insect, termite-proof, effectively eliminate pest harassment, and extend the service life;

- Colorful, many colors to choose from. Both natural wood texture and wood texture, but also according to their own personality to customize the color needed;

- It has strong plasticity, can realize individualized modeling very simply, and fully reflects personality style;

- High environmental protection, no pollution, no pollution, and can be recycled. The product does not contain benzene and formaldehyde. It is an environmentally friendly product. Recyclable use greatly saves the amount of wood used. It is suitable for the national policy of sustainable development and benefits the society.

- High fire resistance. Can effectively flame-retardant, fire rating to B1 level, fire self-extinguishing, does not produce any toxic gases;

- Good machinability, can be customized, planed, sawable, drillable, surface can be painted;

- Simple installation, convenient construction, no complicated construction process, saving installation time and costs;

- No cracking, no expansion, no deformation, no maintenance and maintenance, easy to clean, save the cost of later maintenance and repair;

- sound absorption effect is good, energy saving is good, make the indoor energy-saving up to 30%;

- The SPC floor is less costly than the LVTWPC floor, less labour, less labor, and a neat environment.

Mixer→Spiral loader→SJSZ92 double-screw extruder→Mould→four-roller calender(online laminating)→Cooling bridge→Hual off unit →Transversal cutter→Edge trimming unit→Conveyor→UV treatment→Slitting machine→Slotting machine-Packing

________________________________

Qingdao Weier Plastic Machinery Co.,Ltd

Contact person:Echo Lee

Mobile: 0086-13583286680

Tel: 0086 85213097

Fax:0086-85205396

Web:weiermachine.en.made-in-china.com or weiermachine.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23