Hot Sale High Quality Stainless Steel Complete Automatic Dairy Milk Production Line ...

Shanghai Yongguan Adhesive Products Corp., Ltd. / 2022-07-05

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Milk

- Customized:Customized

=== Base Info ===

- Model NO.:JM-MILK

- Company:Shanghai Jimei Food Machinery Co.,Ltd

- Product Name:Hot Sale High Quality Stainless Steel Complete Aut

- Warranty:Life Long Time Free Technical Support

- Control System:PLC Control

- Capacity:10tone-100tone Per Day

- Run:Convenient and Stable

- Condition:New

- Raw Material:Milk, Milk Powder

- Final Product:All Kinds of Milk

- Material:Stainless Steel

- Transport Package:Wooden Cases

- Specification:Customized

- Trademark:Shanghai Jimei

- Origin:Shanghai

- Production Capacity:8 Units Per Month

=== Description ===

Basic Info.

Model NO. JM-MILK Company Shanghai Jimei Food Machinery Co.,Ltd Product Name Hot Sale High Quality Stainless Steel Complete Aut Warranty Life Long Time Free Technical Support Control System PLC Control Capacity 10tone-100tone Per Day Run Convenient and Stable Condition New Raw Material Milk, Milk Powder Final Product All Kinds of Milk Material Stainless Steel Transport Package Wooden Cases Specification Customized Trademark Shanghai Jimei Origin Shanghai Production Capacity 8 Units Per MonthProduct Description

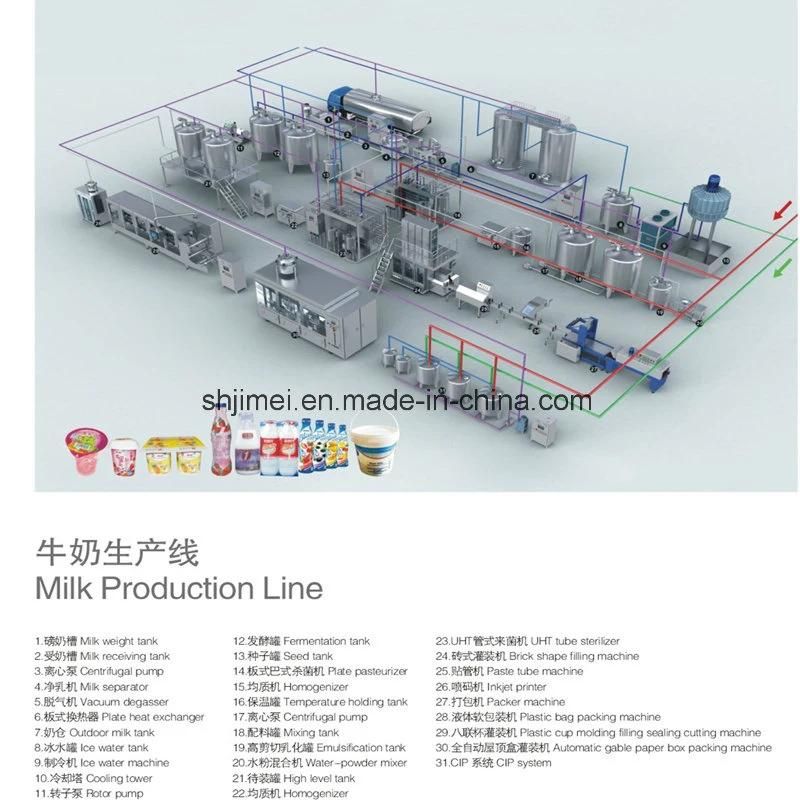

Hot Sale High Quality Stainless Steel Complete Automatic Dairy Milk Production Line Processing Plant MachinesProduct Information

The whole milk production line consists of the following systems:1. Water treatment system2. Suger melt system3. Sterilizer system

4. Filling and packing system5. CIP cleaning system6. After treatment equipments, like conveyor, package or pallet, etc.7. There are other assistant equipments used such as steam boilers, air compressor, cold water unit, etc.8. Installation materials for the process pipline, utility pipeline as well as electrical installation are provided.Filling and packing types can be decided by the customer then designed accordingly.Our company can design customized milk production lines in accordance to the customers' requirements.

The production capacity varies from 500L/h to 50000L/h according to customer's need.

| Raw material | Liquid cow milk, goat milk, camel milk, milk powder dissolving with water |

Product | Pasteurized milk, yogurt, flavored milk, milk drink, sour milk, butter, cheese and so on. |

Capacity | 1T-50T/D |

Product package | Aseptic pouch, gable top box, plastic bottle, plastic cup, glass bottle, plastic pouch, bulk, according to customer's requirement |

Service include |

|

Competitive Advantages

Well and High Quality Control ,

Prompt Delivery ,

New Product ,

Customer's Design and Logo are Welcome ,

Competitive Prices ,

Earth-friendly Products ,

In a Variety of Design ,

Small Order Acceptable ,

ODM Accepted ,

OEM Accepted

About Us

Company Profile

Jimei Holdings Group of China - Shanghai Jimei Food Machinery Co., Ltd. is a collection of scientific research,production and service as one of professional manufacturer of liquid beverage food machinery, high-tech enterprises;the company was founded in 1989 and currently has become a leader in the domestic food machinery industry.

Main Products

automatic roof-type carton packaging machine, automatic paper box packaging machine,automatic paper pillow type packing machine,automatic spray sterilizing unit,PET triple filling unit,UHT tubular , plate sterilization machine, aseptic liquid flexible packaging machines, etc., and the formation of fruit and vegetable drinks production line, liquid dairy production line containing carbonated beverage production line, pure water production line, milk powder production line, cold production lines, concentrated fruit juice and jam production line, canned fruit production line eight series as the main supporting parts of the production line equipment Vice scale Group production mode.

Our Partners

Why Choose Us

Professional After Sale Service

Our engineer will be availalble on site to guide installation and debugging , we also provide free staff training. Further more,Our After Sale service department offering 24 hours 7days service ,we will quickly respond you once you have any question when using our machines.

Long history of the Company

JIMEI is famous for its finest quality and enjoys a long-standing reputation at home and abroad. Having a long history of more than two decades,great experience accumulated in such a long time making us on the top list of Chinese manufacturer professionals in food machine industry.

1.How long can I receive your reply after I send my inquiry?

We will reply you within 12 hours on workday.

2.Are you a manufacturer or a commercial company?

We are a manufacturer, and we have a foreign trade department, we market our own products.

3.What products can you provide?

We mainly produce beverage production machinery and equipment.

4.What are the application fields of your products?

Our products are mainly used by beverage factories or individuals who want to run a milk production plant.

5.Can you provide custom products?

Yes, custom products are our main products. We can develop and manufacture products according to customer's drawing or sample. Saving customer's time on finding corollary equipment.

6.How's your production capacity?

Our annual output is about 800,000 sets.

7.How many employees do you have?

We have over 100 employees, including several technicians and engineers.

8.How do you ensure your product quality?

We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

9.Payment?

We will confirm the payment with you when quoting, like FOB, CIF, CNF or others.

In batch production, we accept 30% deposit, balance against the copy of B/L.

T/T is the main payment, and L/C is acceptable as well.

10.What's your delivery method?

We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

11.Where do you mainly export your products?

Our products are mainly exported to Mexico, Saudi Arabia, India, Algeria, Dubai, Congo, African countries, etc.

Trade Information

1. Package- all equipments packed in nylon cloth and plastic film worthy of sea shipping.

2. Delivery- in 30 days upon receipt of down payments.

3. Warranty-all machines & equipments are of one year warranty and life long maintenance offered by seller.

4. Installation- the seller arrange engineer to set up the equipments and train the operation workers for free, till qualified products are produced and maintenance in normal running, the buyer bear the round air tickets and local accommodation for the seller's engineer.

Our Service

1.Allotted for equipment inspection certificate and manual, to ensure that users properly install and use.

2.Equipment to reach the destination,the company will send engineers to guide installation and commissioning and customer training until satisfied.

3.The warranty period will be free to customers wearing accessories, shelf life outside of my company to provide parts at cost.

4.I provide lifelong maintenance service, including if necessary, to send engineers to the customer at the service.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23