Twin Scew Extruding Machine for Powder Coating Production Line

Shanghai Guorui Hydraulic Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Dimension

(m x m x m)CM-300 300 11 1.5 PLC 2.3x1.1x3 CM-600 600 22 1.5 PLC 2.9x1.5x4 CM-1000 1000 37 1.5 PLC 3.1x1.6x4 CM-2000 2000 55 2.2 PLC 3.6x1.8x4.6

D. Cooling Band Model Thoughput (Kg/h) Screw Diameter (mm) Screw Length

(L/D)Main Motor

(KW)Screw Speed

(rpm)Feeder Motor

(KW)Heating/Cooling

ZoneDimension

(m*m*m)TSK40H 150-200 40 16D 18.5 600 0.55 3/1 2.2*0.6*1.7 TSK55A/55H 300 55 16D 30 750/600 1.1 3/1 2.8*0.8*1.8 TSK55B/TSK55BH 400 55 16D 37 750/600 1.1 3/1 2.8*0.8*1.8 TSK65A/TSK65AH 500 65 16D 45 700/600 1.5 3/1 3.3*0.8*2.3 TSK65B/TSK65BH 600 65 16D 55 700/600 1.5 3/1 3.3*0.8*2.3 TSK75/75H 600/800 75 16D 55/75 600/800 1.5 3/1 3.6*1.0*2.8 TSK85/85H 1000/1500 85 16D 90/110 600/800 2.2 3/1 3.6*1.0*2.8

E. Grinding System Model Throughput

(kg/h)Roll Diameter (mm) Bandwidth (mm) Band length (mm) Power

(KW)Cooling mode Dimension (m x m x m) YPJ600 120 190 600 3500 1.1 cooling water/Air 4.0x0.8x1.2 YPJ800A/800AG 300 245/325 800 4500 1.5 cooling water/Air 5.5x1.1x0.9 YPJ1000A/1000AG 500 245/325 1000 5000 2.2 cooling water/Air 5.8x1.1x1.0

3. Company IntroductionModel Throughput

(Kg/h)Main Motor

(KW)Classifier Motor

(KW)Classifier Speed

(rpm)Fan Motor

(KW)Air Flow

(m3/h)ACM02 0-5 2.2 2.2 Same as main

motor speed1.6 100 ACM04 10-15 3 2.2 0-2830 0.4 150 ACM05 50 4 1.5 2840 5.5 800 ACM20 300 15 3 2900 7.5 1000 ACM30 500 22 4 2900 15 2000 ACM40 800 30 5.5 2900 30 3000 ACM50 1000 37 7.5 2900 37 5000

Yantai Jatchen Powder Coating Processing Equipment Co., Ltd, established in 2011, which specialized in researching and manufacturing of powder coating processing equipment with strong technical team and rich experience. We passed CE certification approval and ATEX explosion resistant test, etc. international standards, "Quality first, Credit first and customer first" is our eternal pursuit. We are committed to provide commissioning and installation support, formulation guidance and 24-hour after-sale service.

Our products have been successfully exported to many countries and regions. like America, Brazil, Canada, India, Turkey, etc. We sincerely welcome you to our company for business visit. we'll try our best to provide the best equipment and solutions to our customers.

4. Workshop View:

We make machining part by ourselves to make sure the timing and quality of our equipment.

5. Patent & Qualification:

6. Why choose us?

"Leading design" + "Excellent performance" + "Best service" = Jatchen's advantages

6.1 Leading design

The richest experienced R&D team, more than 20 years only keeping eyes on powder coating industry.

6.2 Excellent performance

The steep particle distribution result, the biggest savings of materials and labor for your clients.

6.3 Best Service

6.3.1 Online Technical Support

We provide layout design, excellent mechanical engineer, excellent electrician etc. Based on client's requirement,

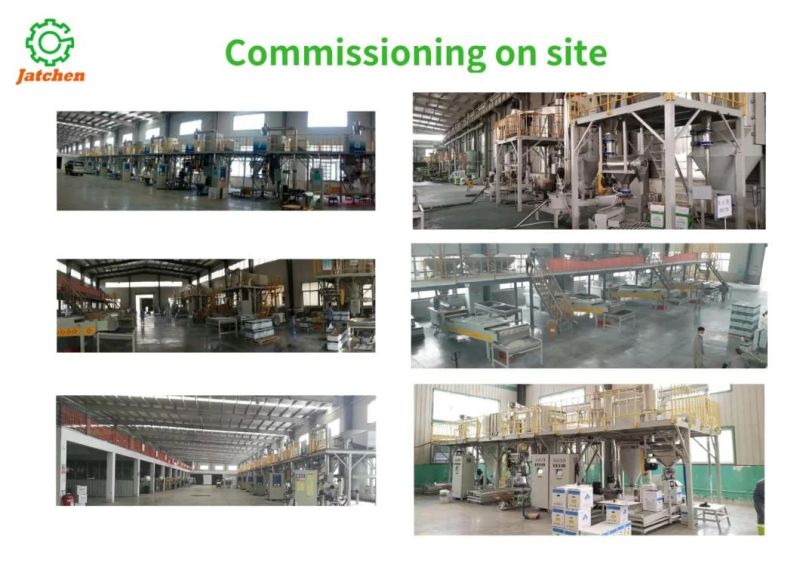

6.3.2 On-site Training support

We provide support training, including installation, commissioning etc.

6.3.3 Long-term Maintenance support

We offer needs-oriented and standardized maintenance packages, such as the overhaul of components, gearboxes.

6.3.4 Spare Parts Replacement and Repair support

Providing spare parts for our all powder coating processing equipment with good material and high precision timely.

7. Successful Cases:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23