Extruder Parts Applied for Composite Materials

Qingdao Enka Industrial Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. Extruder Parts Delivery in 30 Days After The Contract Takes Effect Voltage According to Customers′ Requirement Transport Package Wooden Case Specification W6Mo5Cr4V2 or38CrMoAl Trademark TENDA Origin Nanjing, Jiangsu Production Capacity 3000 Meters/MonthProduct Description

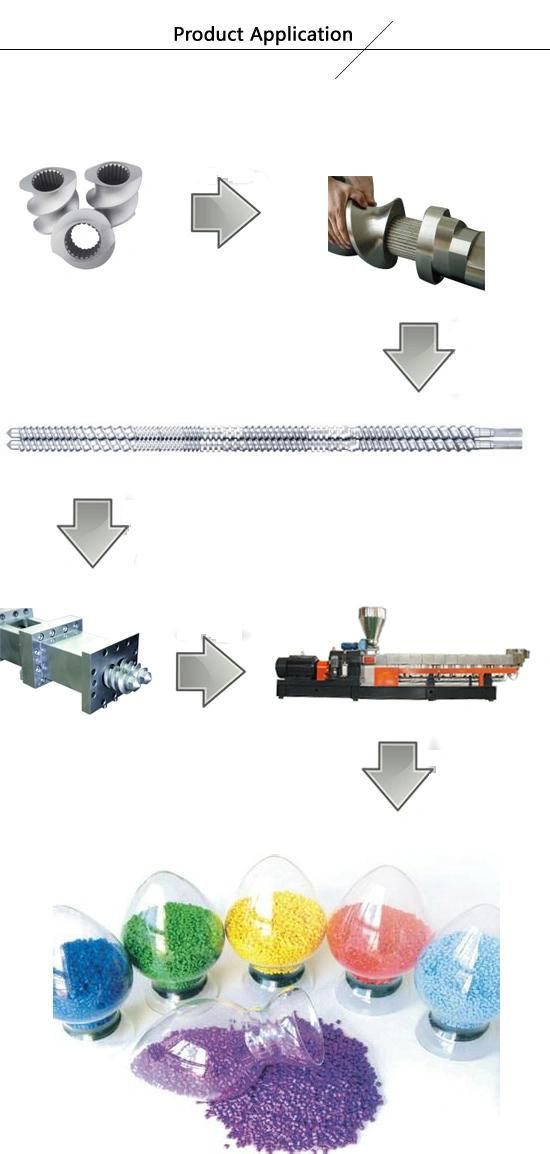

Extruder Parts Applied for Composite MaterialsProduct display

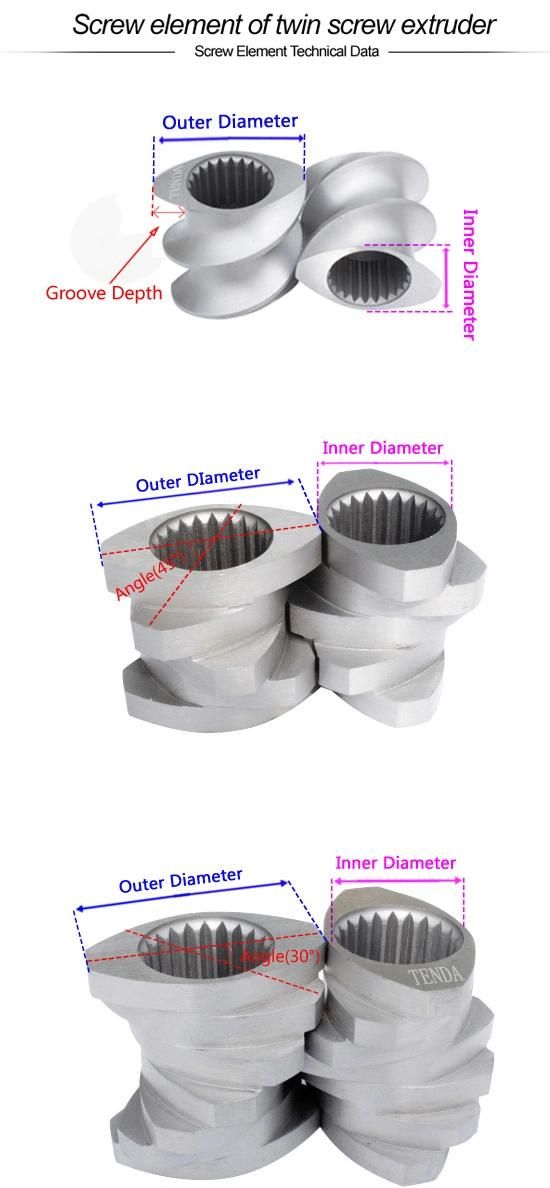

| Type | TD-20 | TD-35 | TD-40 | TD-50 | TD-52 | TD-60 | TD-65 | TD-75 | TD-85 | TD-95 |

| Do(mm) | 21.7 | 35.6 | 41.2 | 50.5 | 51.4 | 59.5 | 62.4 | 71 | 81 | 91 |

| Di(mm) | 14 | 23.6 | 27.2 | 32.5 | 34 | 43.5 | 40.4 | 47 | 52.6 | 63 |

| Groove Depth | 3.85 | 6 | 7 | 9 | 8.7 | 8 | 11 | 12 | 14.2 | 14 |

Main Features:

The screw element is the main component of twin screw extruder.

The stability of extrusion material entirely depends on the quality of screw element.

Through the computer our professionals accurately design the scientific and reasonable screw elements which have self-cleaning capacity.And it is very convenience for customers to clean the screw.

Application example

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23