Agglomerator Two-Stage Recycling /Granulator/Granulating Machine/Extruder/Extrusion ...

Chenguang Machinery & Electric Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. 500 Customized Customized Model No Type-70 Motor Brand Siemens, ABB or Chinese Best Brand Bearing Brand SKF and NSK Hot Washing Tank Included Invertor Brand ABB or Teco Guarantee/Warranty 12 Monthes Capacity Range 90-1200kg/H Color Optional Weight 3-20t Machine Material 304 Stainless Steel Raw Material Film/ Bottle/ Pipe /Bag Belong Plastic Granulator/Pelletizing Machine Object Waste Recycling Granulator System Machine Name Plastic Recycling Pelletizing Granualtor Machine Transport Package Nude and Wood Packing Specification According to the actual requirement to configure Trademark Boxin brand Origin China HS Code 8477800000 Production Capacity 60sets/YearProduct Description

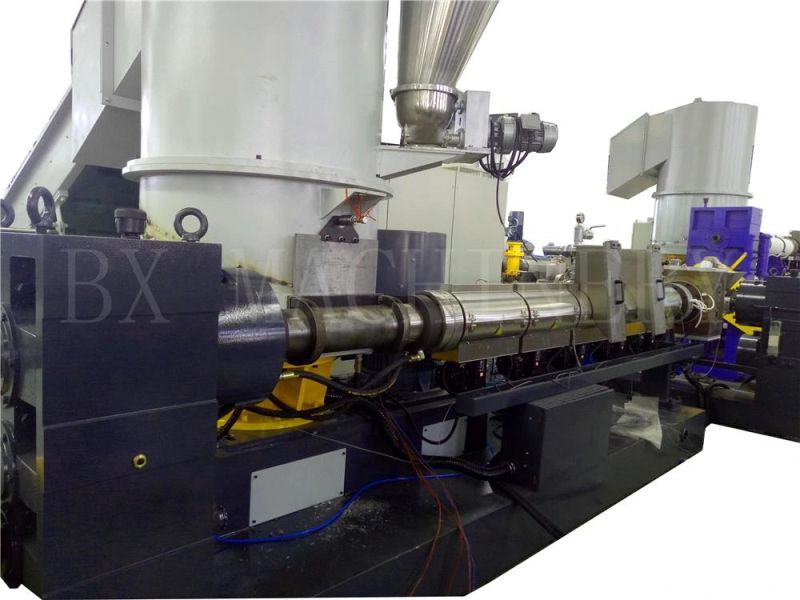

Plastic Film PP PE PET EPE EPS BOPP raffia woven-bag film jumbo bag Recycling granulator with compactor/Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic 1. introductionThe BX series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step, applied in the plastics recycling and pelletizing process.BX series machine is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic productions produced by BX series machine are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

2.Specifications:

| Model Name | BX series Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic |

| Recycling Material | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Final Product Shape | Pellets/ Granules |

| System Composition | Belt conveyor, cutting compactor, single screw extruder, pelletizing device, water cooling unit, dewatering section, conveying blower and production silo |

| Output Range | 90kg/h-1200kg/h |

| Feeding Device | Belt conveyor (standard), Rolls hauling off device (Optional) |

| Compactor Volume | 300-1400 Liters |

| Screw Diameter | 65mm-200mm |

| Screw material | 38CrMoAlA nitride steel( SACM-645), bimetallic ( Optional) |

| Screw L/D | 28/1, 30/1, 33/1, 36/1 (depending on features of recycles) |

| Barrel's Heating | Ceramic heater or Casting Aluminum heater or Electromagnetic heating |

| Barrel's Cooling | Air cooling through fan blowers |

| Vacuum Degassing | Double vented degassing (Standard) or single vented degarssing |

| Pelletizing Type | Water ring die-face hot pelletizing |

| Voltage Standard | Depending on project's location |

| Optional Devices | Metal detector, rolls hauling off device, micro feeder for masterbatch, additives, chiller, etc. |

| Delivery Time | 60 days after order takes effect. |

| Warranty | 13 months since date of bill of lading |

| Technical Service | Project design, suggestion on factory construction, installation and commissioning |

4.Working steps of the pelletizing system

1. Feeding: Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic ,as standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls' scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor's room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding section.

2.Crushing and compacting: Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic ,the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3.Plasticization and degassing: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 32 to 34D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

3.Plasticization and degassing: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 32 to 34D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

4.Melt filtration: Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic ,a regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

5..Pelletizing: Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic ,die-face water ring pelletizing system set as the standard granulating method in ACS system. Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high performance dried pellets.

5..Pelletizing: Shredding and Pelletizing compounding single-screw recycling profile /granulator/granulating machine/extruder/extrusion food system equipment line for plastic ,die-face water ring pelletizing system set as the standard granulating method in ACS system. Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high performance dried pellets.6.Quality Control(plastic machine):

.In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

.Each component before assembly needs strictly control by inspecting personnel.

.Each assembly is in charged by a master who has working experience for more than 5 years

.After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

7.Service System(plastic machine):

.After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

.After the commissioning, we will package the equipment by standard export package for shipment.

.According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

.Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

8.Package and Loading

10.FAQ

Innovative research and design team with 20-year experience in plastic recycling industry.

1. Are you manufacturer or trading company?

We are a professional recycling machines manufacturer for more than 15years we supplying full technical support and solutions, timely and professional service, always effort on quality, honest, win-win business for every client.

2. How do you assistant to install the machine on worksite?

We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation, commissioning.

3. How can I get spare parts for replacement in other countries?

Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent or by sea within 5days.

4. Can I use mark machine with different LOGO and color?

Yes, please confirm details with sales.

5. Can your customers test the machines?

Before buying and after production before leaving factory, we test machine you interested or paid with specified materials, free of charge.

6.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

If we can fullfill your request and you interested in our products, you may pay a visit to our site

The meaning of visiting supplier, because seeing is believing, we with our own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

If you have any need ,pls feel free to contact with us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23