Disk Screener for PET Bottle Washing System

Zhecheng Hongxiang Superhard Material Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TTS2732 Specification 3722*3377*2902mm Trademark BORETECH Origin China HS Code 8479820090 Production Capacity 3-4 Sets Per Quarter Based on Orders in StoreProduct Description

Disk Screener for PET Bottle Washing SystemSieving machine is used to separete solid waste such as sand, metal, small stone, labels in PET bottle recycling process. It helps the PET bottle washing by reducing equipment abrasion, material loss to enhance productivity. Flakes sieving improve the quality of final PET flakes.BoReTech supplys three types of sieving machines, dry trommel,disk screener and dust remover. Disk screener is more compact than the dry trommel, it can be placed after de-baling and pre-washing then remove

sand, labels and so on. It can evenly disperse the bottles onto the next process and remove remained water.

Dry trommel can remove caps and sands separately by multiple mesh sizes.

Dust remover can separate dust in the flakes, small plastic labels and film by taking advantage of the gravity and machine structure design.

| Model | Capacity(kg/h) | Power(kW) | Vibration Frequency(times/min) | Shaft Quantity(Pcs) | Demensions(mm) |

| TTS1223 | 3000 | 3 | 400 | 11 | 2814*1977*2513 |

| TTS2732 | 6000 | 5.5 | 400 | 15 | 3722*3377*2902 |

Our Advantages

BoReTech supplys three types of sieving machines, dry trommel,disk screener and dust remover. Disk screener is more compact than the dry trommel, it can be placed after de-baling and pre-washing then remove

sand, labels and so on. It can evenly disperse the bottles onto the next process and remove remained water.

Dry trommel can remove caps and sands separately by multiple mesh sizes.

Dust remover can separate dust in the flakes, small plastic labels and film by taking advantage of the gravity and machine structure design.

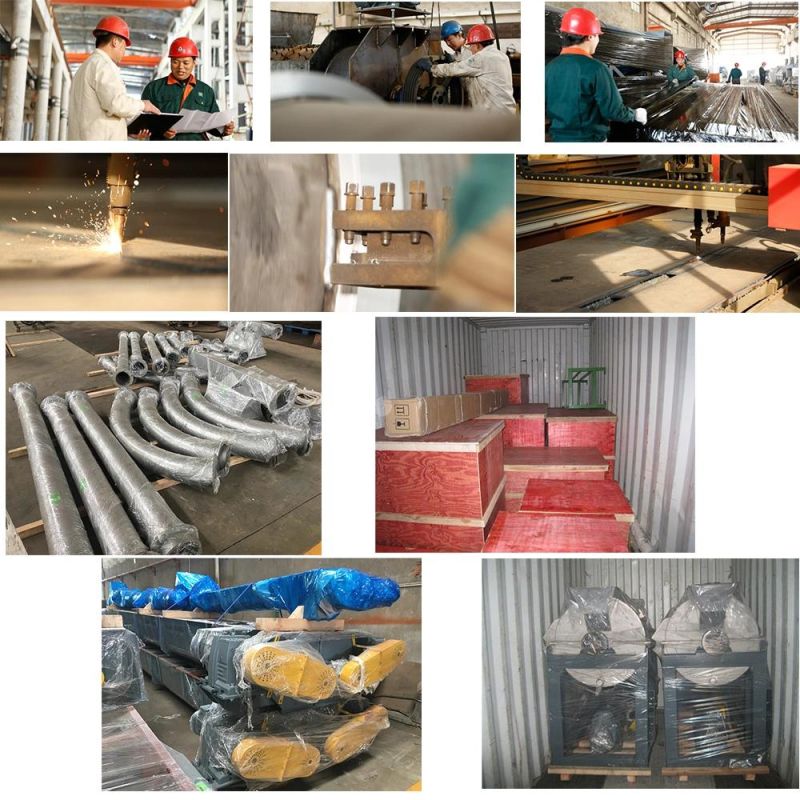

Our service1,pre-sale support:Normally we suggest you paint our standard color , but we can supply customization paint service by paid.2,after-sale service:Warranty:1 year for machinery,6 months for electrical.

For mechanical parts, our guarantee duration is 12 months. If the part is broken within this period, we will send the spare parts immediately to the client for repairing.

3,technical support:

Normally, we send our engineer(s) to supervise the installation and commissioning. The buyer need to prepare the operation staff to implement it. BORETECH is able to send mechanical engineer, electrical engineer and operation engineer. The operation engineer is to help the buyer's labors to know how to operate the washing line and get the best efficiency.

Boretech Brief

Boretech is one of the major supplier of PET bottle recycling system in Asia . We uses the around 30 years of fiber making and bottle recycling experiences to manufacture PET Bottle recycling machine and configure Pelletizing line, Polyester Staple Fiber line, POY line and Bottle to Bottle Line. At present, we have supplied about 170 sets plant for more than 30 countries.Our customers in the US, Japan, EU manufacture food grade rPET resin for such well-known brand owner's such as Coca Cola, Niagara Bottling, Nestle, etc.

Boretech can help our customers to make right configuration of the machinery, and find the right position in the industries. The most important value is that we can help our customers to minimize the learning cost and to avoid making any mistake during investment.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23