PP PS Pet Single Double Layer Sheet Extrusion Line

JIAXING JIANHE MACHINERY CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

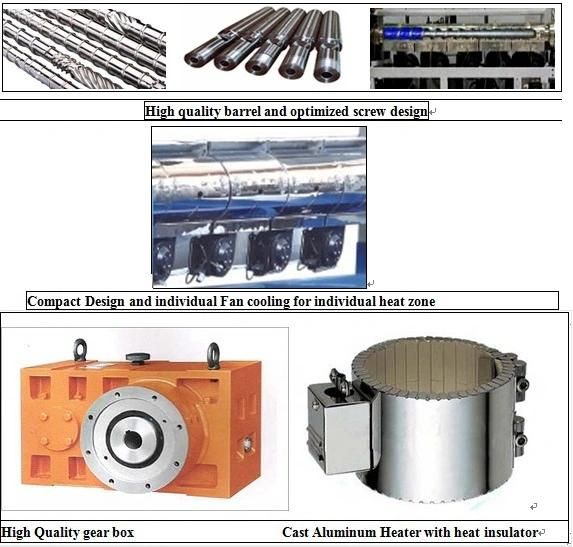

1.Main Extruder

a- Output: 150kg/h-300kg

c- Material of screw and barrel: 38CrMoAlA high quality alloy steel, nitriding 0.4-0.5mm

d- Diving motor:55kw, frequency inverter 55kw. ,

c-Heating :30 kw, 6kw*5 heating zones on barrel,air cooling by blowers, 0.05kwx5

d-Cast Aluminum Heaters,more even and relaible heating with heat insulator

e-Cooling in Gear box,12.5:1

1-1.Sub-Extruder

a- Output: 70kg/h

b- Screw: diameter80mm, L/D 32:1 , Max.Speed 90rpm

c- Material of screw and barrel: 38CrMoAlA high quality alloy steel, nitriding 0.4-0.5mm

d- Diving motor:37kw, frequency inverter37kw ,

e-Heating :21 kw, 4 heating zones on barrel,air cooling by blowers,

f-Cast Aluminum Heaters,more even and reliable with heating isolation for saving power

2.Screen charger

a- Material : 38CrMoAlA high quality alloy steel , nitriding

b- Hydraulic charger ,Two performancestation,motor:1.5kw

c- Screen Heating Power.3.5kw , flow channel heat 3kw

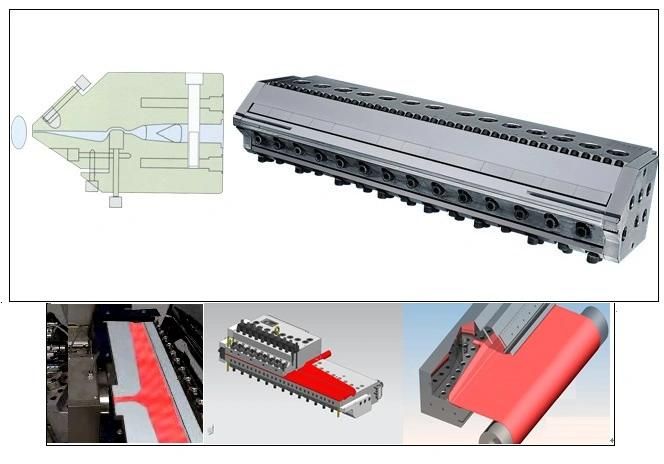

3. Die

b- width,800mm ,adjustment range 0.15-2.5mm

c- Material: carbon constructional quality steel chrome-faced chromized coating

d-Heating :5 kw* 3 zones

e-Structure :T-shaped ,Clothes bracket flow channel, polished inner mold surface.

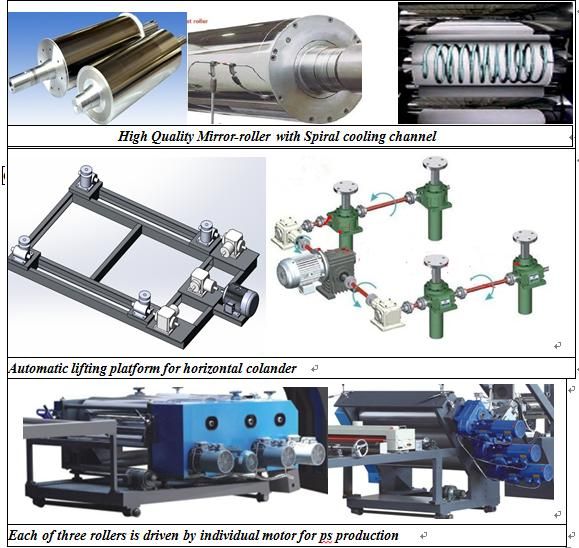

4. Calander of 3 rollers

- Mirror face,Spiral cooling channel

- thickness adjusted by screw , position adjusted by motor 1.5kw

- Individual motor drive for each roller

- Motor,2.2kw Frequency converter control ,2.2kw, Frequency Inverter

- Motorized adjustment of height of calander

- horizontal type calander for lower thickness of sheet making

5.Haul-off unit

a- Ф50mm×1200mm

b- Motor:2.2kw, frequency converter control,2.2kw , Frequency Inverter ,

c- Haul-off length 2000mm

- Scrap Rewinder:0.75kw*2

6.double rewinder

a- Max.sheet roller diameter 650mm, 300kg each roller

b- 2* torque motor for rewinder

c- 360 rotation for 2 stations of rewinder

7. control

a- Temperature rises or lowers by increasing or decreasing voltage.

b- Temperature controller with Solid state relay .

c-Cast Aluminum Heaters ,more even and relaible temperature control

d-independent electric cabinet .

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23