Plastic Bottle Recycle/ Pet Bottle Recycling Machine/ Pet Bottle Washing Line

Fujian Quanzhou Huazuan Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Moisture: max 3%

Bulk density: 0.3G/CM3

Particle size: 10-18mm

Metal content: max.20ppm

Floatable contamination: less than 200ppm

Total impurity: 100-320ppm

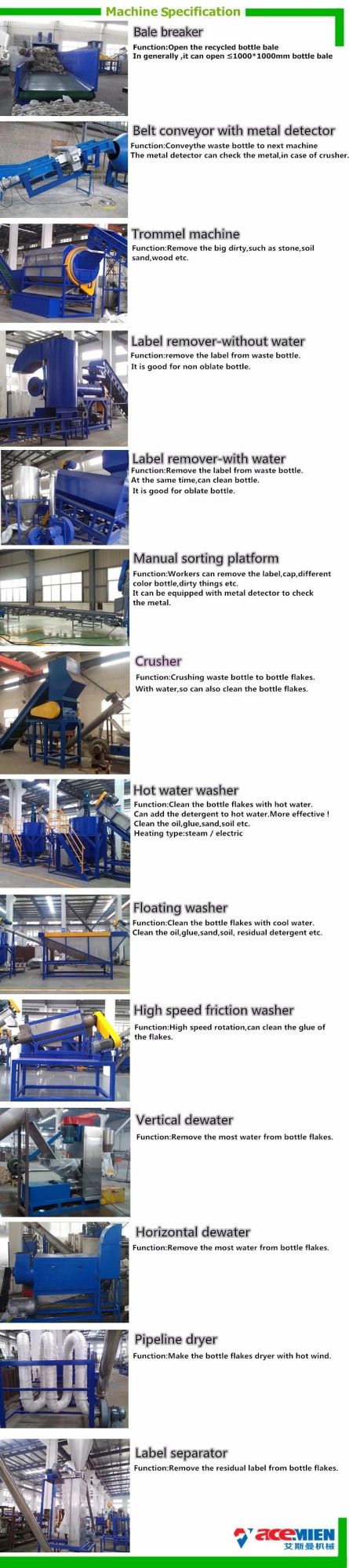

common configuration of pet bottle plastic recycling machine/plastic washing machine/waste plastic bottle recycling plant

| No. | Equipment Name | Quantity | Comments |

| 1 | Belt conveyor | 1 set | |

| 2 | Bag opener | 1 set | Optional |

| 3 | Belt conveyor | 1 set | |

| 4 | Trommel | 1 set | Optional |

| 5 | Belt conveyor | 1 set | |

| 6 | Manual sorting conveyor | 1 set | Optional |

| 7 | Belt conveyor | 1 set | |

| 8 | Crusher | 1-2 sets | |

| 9 | Screw conveyor | 1 set | |

| 10 | Washing tank | 1 set | |

| 11 | Screw conveyor | 1 set | |

| 12 | Cooking boiler or Horizontal Hot washer | 1-2 sets | |

| 13 | Screw conveyor | 1 set | |

| 14 | High-speed washer | 1 set | |

| 15 | Washing tank | 1 set | |

| 16 | Screw conveyor | 1 set | |

| 17 | Horizontal Dewatering Machine | 1 set | |

| 18 | Cyclone separator | 1 set | |

| 19 | Drying system | 1 set | |

| 20 | Label separator | 1-2 sets | We can equipped with two label separators in the whole line, one at the beginning, another at the end |

| 21 | Final product silo | 1 set | |

| 22 | Control System | 1 set |

Our Service

1. Turn key project

2. Technical documents

We will offer you all necessary documents, e.g. general layout plan, water scheme, electrical diagram and user manual after the contract is executed.

3.Arrangement for inspection, installation and testing work

We will inspect and test the machine in our factory first before shipping the machine. Customers are welcome to come and check the working machine, until the machine produces the exact products as customers requirements, and learn operation in our factory.

After the machine is delivered to customer's factory, we will send one or two technicians to customer's factory for on-site installation and commissioning of the whole machine line. Meanwhile, technicians will give free training lessons to workers in customer's factory.

4.The guarantee period of the whole machine is 15 months.

5.Technical support from our factory is free of charge for all the life; quick response to any questions from customers.

Why choose us:

1. Low cost : all the machines ,we make them by ourself to reduce the cost for our customers.

2. Genuine product with excellent quality : we choose our material very strict, all the material come to our factory must pass the quality test substandard goods are returned to the supplier.

3. Engerneers available to serve oversea.

4. Quick delivery: the company provide just in time delivery with its streamlined supply chain.

5. Cost saving: we take strong attention to every detail in the manufacturing process,the quality control in our factory is very strict, all defective semi-manufactures must be treated again or reject. all the machine must be checked out ,then deivered to our customer. all about that pushing up the price, what we want to do is give our customer a good quality product with stable working and long lived.

FAQ

1.Q: Are you an industry manufacture factory or a foreign trade company?

A: We are an industrial manufacture factory of plastic extrusion machinery and auxiliary equipment, which locates in Zhangjiagang city, China.

2.Q: Payment term:

A: Loading Port: Shanghai by sea or by train.

T/T, L/C, West Union, or Cash, etc.

3.Q: Do you have any other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers' requirement.

4. Q:How do you make the quotation for clients?

A:The price depends on quality and performance but the clients should be satisfied first.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23