Plastic Barrel Shredder and Crusher Two in One Machine

Ou Zhou Industrial Products (Kunshan) Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

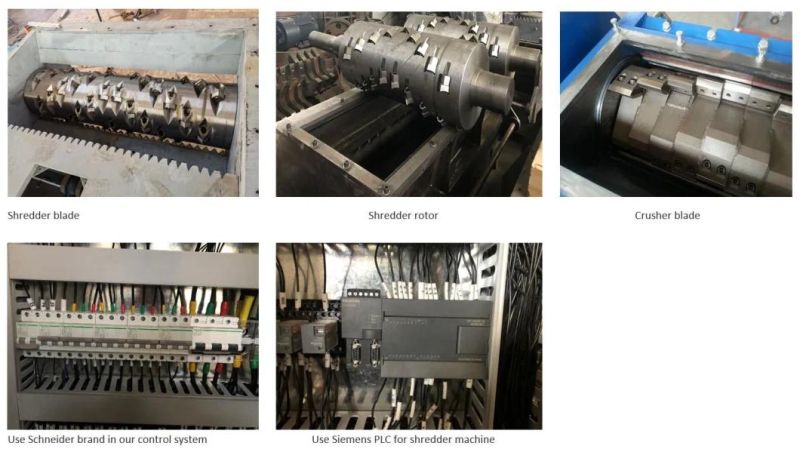

Model NO. XRU600 Knife Roll Solid Knife Roller Automation Automatic Computerized Computerized Certification CE, ISO9001:2008, UL, SGS Shredding Room 600*600mm Shredder Rotor Diameter 280mm Crusher Rotor Diameter 300mm Blade Materials SKD11/D2/DC53 Gear Box Guomao or Boneng Bearing Heavy Duty Bearing Motor Brand Simo/Wannan/Siemens/Weg Voltage According to Customers Shredder Rotating Speed 80rpm Crusher Rotary Speed 600rpm Screen Size 8-16 mm Main Electric Element Schneiders/ Siemens Capacity 300-500 Kg/Hr Weight 3300 Kg Transport Package Wooden Case Specification XRU600 Trademark FAMOUS Origin China HS Code 84778000 Production Capacity 2set/MonthProduct Description

Plastic Shredder and Crusher Two in One MachineProduct Description:

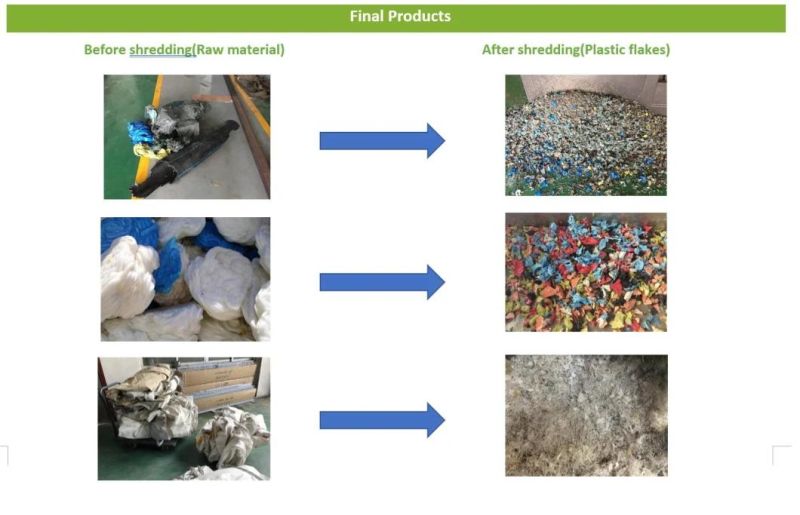

This shredder and crusher two in one machine is our company new design. raw material goes into crusher machine directly after shredding by single shaft shredding machine. It used for the die material, big block material, plastic pipe, wood, barrel and other plastic material. By this method, customer no need to buy belt conveyor between these two machines, so it will save cost.

waste plastic shredder and crusher in one machine has two parts in one machine, one is shredding part on the top for coarse crushing, the other one is crushing parts under the shredding part for fine crushing to get 8-16mm particle materials. It is an efficient recycling machine for recycling the waste plastics, for example, plastic lumps from injection or extrusion machine, plastic pipes, plastic bottles, plastic baskets, plastic shells of household appliances (e.g. TV, computer, refrigerator, washer machine, etc), and so on.

By equipped with different blades and driving system, the waste plastic shredder and crusher in one machine can be also used for wood, cardboard, copper cables, etc.

Machine Features:

Efficient one step treatment for plastic recycling

A new type of shredding-crushing machine is specially designed for the recycling and regeneration of the material which can not be size reduced only by one crusher, such as the lumps, solid materials, bulk materials or soft materials.

waste plastic shredder and crusher in one machine has the following characters:

1, shredding and crushing function on one machine. Discharged particle materials can be reused directly.

2, main shaft is driven by gear reducer, big torque, steady working and low noise.

3, hydraulic feeding mechanism, independent power unit, strong frame structure.

4, SKD-II blades for efficient working and long life.

5, hydraulic system with water cooling design.

6, electrical cabinet with Siemens PLC control system, auto control for co-rotation and reversal.

7, Auto protection while over-load.

8, Shredder, crusher and storage system combined into one machine, save space and cost.

9, Material strength will decrease sharply after shredding, lower crusher stress while improve knife service life.

10, Suitable for all kinds of solid plastics, such as pipes, lumps, hollow vessel etc.

11, Total machine is controlled by a set Siemens PLC system, machine realize stable and safe working by automatic control of shredder, crusher and storage efficiency.

12, small occupation area in workshop.

13, with CE ISO certification.

Suitable Products:

This machine can shred plastic lumps, barrels, pipes, wood, wood pallet, big block material, plastic container, plastic chair, plastic pallet, woven bags, jumbo bags, cable etc.

Product Parameters:

| Model | Stationary Blades | Rotating Blades | Chamber Dimension | Power | Mesh Size |

| XRU600 | shredder(2pcs)+crusher (2*2pcs) | shredder(26pcs)+crusher(3*5pcs) | 280 mm | 22kw+18.5kw | 8-16 mm |

| XRU800 | shredder (2pcs)+crusher (2*2pcs) | shredder(34pcs)+crusher(2*3 pcs) | 380 mm | 37kw +30kw | 8-16 mm |

based on shredding different material requirements, please call us for more information before purchasing.

Our Service

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email.

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea. After delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free.

If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you

request. We will tell you the tracking number after delivery.

Service After Sale

1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

Q: Are you a factory or a trading company?

A: As a professional manufacturer, we have been in plastic recycling machine industry for more than 30 years, our factory is in Zhangjiagang city which is near shanghai and wuxi.Q: Do you have any certifications?

A: Yes, we have ISO, CE, SGS.Q: What's your guarantee or the warranty of the quality if we buy your machines?

A: We offer you high quality machines with 1 year guarantee and supply life-long technical support.Q: When can I get my machine after I paid?

A: Normally production time is around 45-75days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.Q: How to install my machines when it arrives? how much the cost?

A: We will send the instruction manual and videos to you, your workers can install the machine according to it. If you still haveproblems in installing it and need our engineer to help, we will arrange our engineer to debugging the machine for you. At same time our engineer will give training lessons to workers in your factory.

Customer pay for visa, round air tickets, accommodation and USD100/day/person.

Q:How long time for installation?

A:According your machines order, we will send one or two engineers to your plant, it will take about 5 days to 10 days.Q: How about the spare parts?

A: We will send one year enough easy broken spare parts together with the machines, shipping together. During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If it is caused by your incorrect operations, we will provide the spare parts at cost price.IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO CONTACT WITH ME.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23