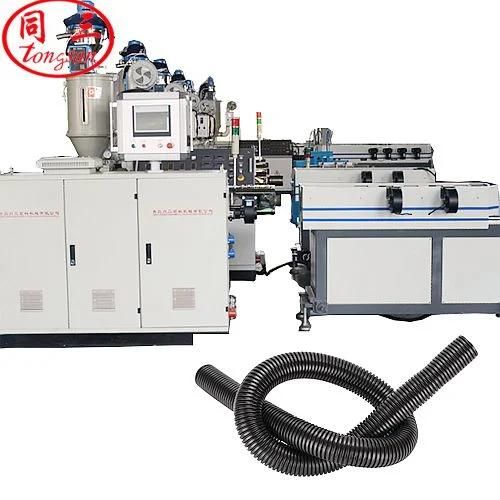

Plastic Pipe Making Machine/Single Wall Corrugated Pipe Machine/Corrugated Electric ...

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SDBGZ-63 Customized Customized Condition New After-sales Service Professional Engineers Teach Operation Name Single Wall Pipe Extrusion Line Product Color Tongsan Color Suitable Material HDPE/PE/PVC/PP Keywords Pipe Making Machine Heating Way Electrical Heating Transport Package Wood Block Fixed Steel Wire Reinforcement Specification 16-63mm Trademark Qingdao TONGSAN Origin Qingdao, China HS Code 84772090 Production Capacity 24/YearsProduct Description

TONGSAN is PP PE PVC PA Single Corrugated Pipe Extrusion Line Manufacturer Since 1997! Thousands sets of extrusion lines have supplied to global customers.

PP PE PVC PA Flexible Corrugated Pipe Machine can produce single wall corrugated pipes for electric conduit, cable protection, water drainage, shisha hose etc.

Plastic Flexible Corrugated Pipe Extrusion Line Model

| Pipe diameter range | 4.5mm-12mm | 9mm-32mm | 12mm-50mm | 50mm-110mm |

| Model of extruder | SJ45 | SJ50 | SJ65 | SJ65 |

| Production capacity | 20-30kg/h | 40-50kg/h | 60-70kg/h | 70-90kg/h |

| Power of extruder | 7.5kw | 15kw | 30kw | 37kw |

| Power of forming machine | 1.1kw | 1.5kw | 4kw | 4kw |

| Pairs of modules | 42pairs | 50pairs | 50pairs | 70pairs |

| Cooling mode | Wind&Water cooling | Wind&Water cooling | Wind&Water cooling | Wind&Water cooling |

| Production speed | 6-10m/min | 8-12m/min | 8-12m/min | 2-6m/min |

PP PE PVC PA Flexible Corrugated Electric Conduit Pipe Machine Production Process:

Material Loading- Extruder-Die Head and Core Bar-Mould Chain-Forming Machine (Corrugator)-Winder

Single Wall Corrugated Pipe Extruder

Plastic Corrugated Pipe Forming Machine (Corrugator)

Corrugated Pipe Double Position Winder

Flexible Corrugated Pipe Production Line Workshop and Exhibition Show

Company Introduction:

Qingdao Tongsan Plastic Machinery Co.,Ltd is one experienced plastic machinery manufacutrer since 1997.

Our Motto

Quality is the style of TONGSAN.

Credibility is the personality of TONGSAN.

Innovation is the pursit of TONGSAN.

Exhibition

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

Contact me

We look forward to have the opportunity to work together with you in the future.

Alan Jia

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23