Good Quality Tomato Paste/Sauce/Ketchup Making Machine Processing Line

Yuyao Jingdu Sprayer Co., Ltd. / 2022-07-04

- Processing Material:Animal Raw Materials, Agronomic Products, Natural Ingredients

- Application:Pet Food, Dairy, Food

- Customized:Customized

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Semi-Automatic

=== Base Info ===

- Model NO.:STB-TOM

- Name:Tomato Sauce Production Line

- Raw Material:Concentrated Tomato Paste

- Final Product:Tomato Sauce , Tomato Ketchup

- Final Product 2:Tomato Puree and Jam, Tomato Juice

- Transport Package:Wooden Case

- Specification:can be customized

- Trademark:STB

- Origin:Shanghai

- HS Code:8438200000

- Production Capacity:20set,Year

=== Description ===

Basic Info.

Model NO. STB-TOM Name Tomato Sauce Production Line Raw Material Concentrated Tomato Paste Final Product Tomato Sauce / Tomato Ketchup Final Product 2 Tomato Puree and Jam/ Tomato Juice Transport Package Wooden Case Specification can be customized Trademark STB Origin Shanghai HS Code 8438200000 Production Capacity 20set/YearProduct Description

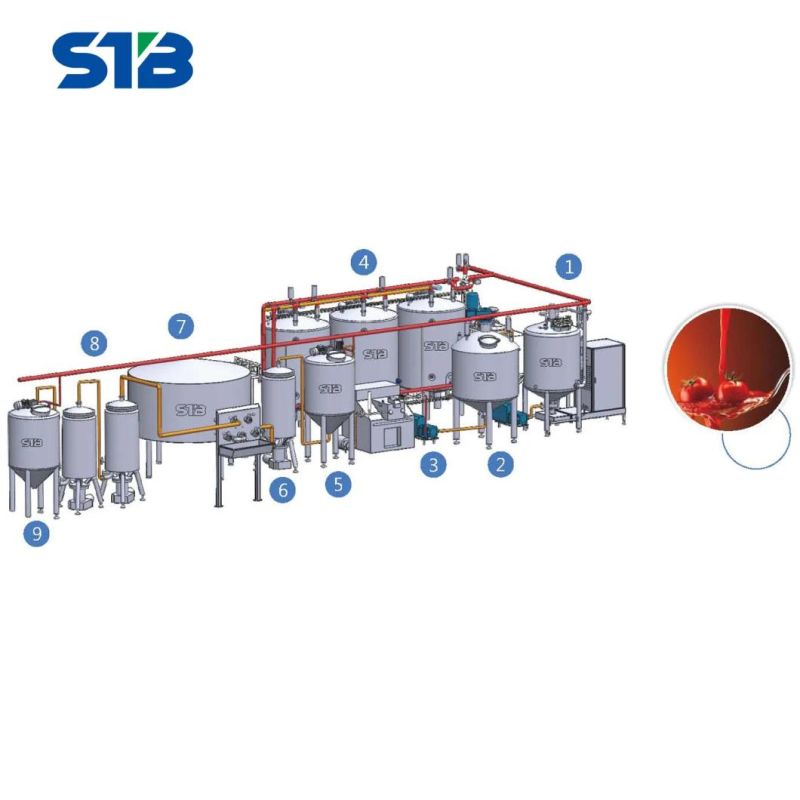

1.Vacuum mixer: Ingredients mixing

1.Vacuum mixer: Ingredients mixing

2. Buffer Tank: Buffering after mixing

3. Homogenizer: Produxts homogenized

4. CIP cleaning system

5.Buffer tank: Buffering after homogenizer

6.Scraper heat exchanger: Heating

7. Holding line: Sterilization and starch gelatinization

8. Scraper heat exchanger: Cooling to 25ºC

9. Pre-filling tank

_____________________________________________________________________

Sauce production

Ketchup,mayonnaise,salad dressing,custard,non-dairy creamer,coconut cream etc. are much important for our life which take better taste of foods.

Due to semi-solid status, sauce is not easy to handle during process, especially during sterilization.

_____________________________________________________________________

CCP Of Quality:

Formula

Mixing&emulsifying process

Oranoleptic index: color,viscosity,flavor

Physicochemical index: fat,protein,PH,salinity,acidity,denseness,density,brix

Microbiology index: process design,SOP,online quality control,microbiological detection

Storage&transporation: temperature,humidity,light etc.

_____________________________________________________________________

Quality defect analysis:

Products seperate: emulsifying process not good, emulsifying structure not stable

Color change: too much oxygen involved in, fat oxidized

Taste: emulsifying not enough, incorrect thickener, low oil content

Unpleasant smell: overcooked,untreated metal ion

Microbiology out of limit: formula or processing defect, disabled microbiology control

Poor bake performance: formula defects, incorrect emulsifier and thickener

_____________________________________________________________________

Solutions:

Our Vacuum mixer could used for pre-mixing tank which equipped bottom high shear mixer and agitator to get fully emulsified and homogenized sauce, dead corner free, no air bubble in final products.

All processing could be controlled automatically.

Scraper heat exchange used for sterilization and cooling after that, 100% sterilization guarantee to ensure products taste and shelf life.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23