Spc Flooring on-Line Embossing Extrusion Production Line

Forsun Ultra-hard Material Industry Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SZJZ110 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Dimension (L*W*H) 23m*3m*3m Transport Package PE Wrapping Film, Fumigating Wooden Cases. Specification CE, SGS Trademark BOYU Origin Wuxi, Jiangsu, China HS Code 8477209000 Production Capacity 1000~1350kg/HProduct Description

Spc Vinyl Stone Plastic Composite Flooring Plank Extruding Making Machine

SPC flooring stands for Stone Plastic Composite. It is the newest generation of high-quality resilient flooring. SPC flooring is an upgrade of Luxury Vinyl Tiles (LVT). No matter laying them on concrete, ceramic or existing flooring. It has a unique interlocking-edge design (advanced "click" system) for easy installation.The main component is lime stone (calcium carbonate)+ PVC Powder + Stabilizer. Different from regular vinyl floor, there is no plasticizer inside, so it is more environmentally friendly. SPC flooring mainly structured with the UV Coating , wear resistant layer, decorative film and core board. Meanwhile IXPE option available for high end usage.

SPC floor is a new and high-tech environmental protection floor decoration material. It is one of the perfect substitute for the wood floor as per the properties and features of non-toxic, no smell, anti-corrosion, wear-resistant , with good decoration effect, convenient installation and simple maintenance.

I. Basic Information:

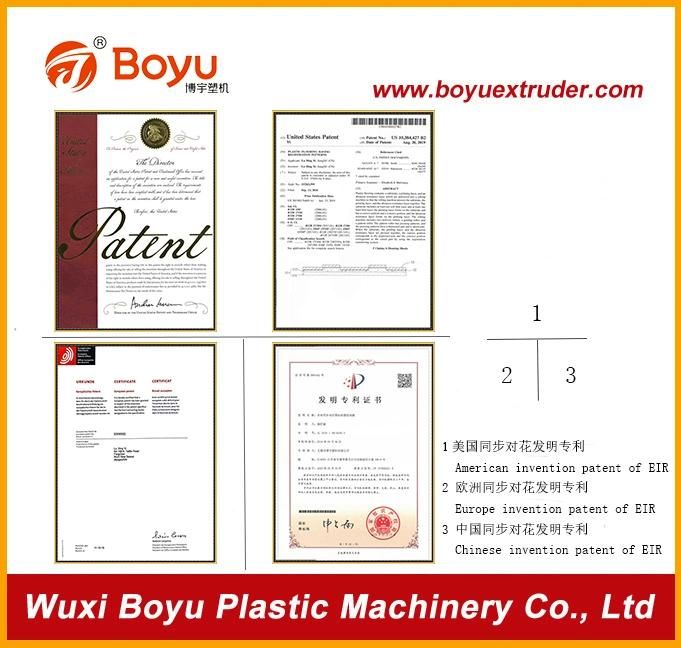

Brand Name: BOYU

Screw Design: Conical Twin screw

Model Number: SJSZ 110/220

Voltage: 380-440V

Main Motor Power: 200kw

Capacity: 1000kg/h ~ 1350kg/h

Dimension (L*W*H): 23m*3m*3m

Weight: 25~32T

Packaging Details: PE wrapping film, fumigating wooden cases.

Delivery Details: 30 working days.

2. Product Configuration:

1) Main motor: SIEMENS BEIDE

2) Contactor: SIEMENS

3) Auxiliary relay: SCHNEIDER or DELIXI

4) Temperature control system: DELTA PLC Touch Screen Control System

5) Inverter: ABB

6) All Extruder by the DELTA PLC Controlled.

3. Production Introduction:

| No. | Items | Data |

| 1 | Operation conditions | 380V/3 phases/50Hz, DC24V. |

| 2 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant |

| 4 | Main material proportion | PVC: CACO3= 1:3 |

| 5 | Product specifications | Width is 1050mm;Thickness:2~9mm |

| 6 | Extrusion line mode | SJSZ110/220 conical twin screw extrusion line |

| 7 | Quality standard | Twin screw standard JB6492-2001 Electricity standard: GB5226.1-2008/IEC 60204-1:2005 |

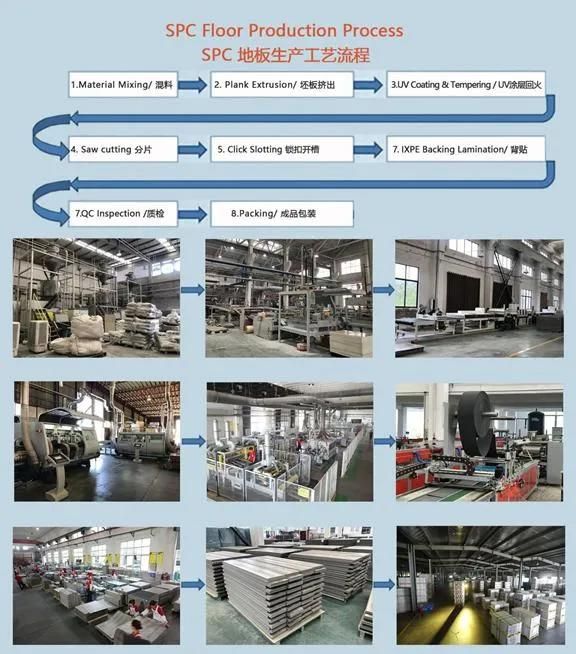

4.Production process:

The screw feeder takes the material from the silo → The Extruder Feeding Hopper → The extruder → Material Plasticizing → T-die → Calender→Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet(Optional) → Traction Machine→ Cutting Machine →Automatic Stacking Machine

5.Finished Products:

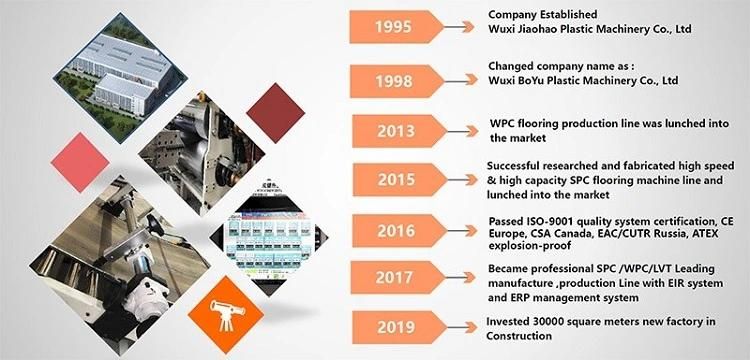

6. Boyu Company Development:

7. Advantages of BOYU SPC Production Machine Line

1. More than 20 years experience on palstic machinery designing and manufacturing:

Leading industry level of mechanical and electric design

Various of machine lines for optional

Provide flooring production proposal of expert level

Proposal customized as per different market demand

High Stability, performance, safet

High efficiency smart equipment, less operator needed

2. EIR(High Quality&High Depth Embossing Performance)

The word leading level EIR technology

The unique one key embossing function is effectively short operation time

Deep embossing is helpful to achieve products differentiation

Constant tension system for film unwinding

Automatic deviation rectification system for film unwinding

3. Simple and Smart Electric Control System

PLC smart control system

Profinet connection method, to ensure fast data communication and achieve remote monitoring

Adopted famous internationla brand of electrical elements , much more decrease the faluts ratio.

Synchronous line speed control system

Anti-screw breakage, anti-bloacking die, automatic stacking control system

Automatic oil/water temperature control system

8. Our Service:

1. Pre-sale service:

To provide market research information and consultation;

To provide all kinds of convenience and market service;

To help customers make project planning and systematic analysis;

To maximize customer's satisfaction.

2. After-sale service:

To install products and test products for customers;

To provide the formulas and technologies of relevant products and the information of chemical materials manufacture;

To provide technical direction according to customers' requirements;

To provide technical training for clients' employees;

To be responsible for maintenance service, door-to-door service under necessary circumstance.

3. Technology Support

Provide different products for formula and material supplier.

Production technology&Technical guidance.

Technicians dispatching for Guidance and technology exchange.

9. Shipping:

10. Certificate:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23