New Technology Kellogs Corn Flakes Making Machine

Yuyao Mingbang Spray Packing Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001, BV

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips, Puff Snacks; Breakfast Cereals; Corn Flakes

- Customized:Customized

=== Base Info ===

- Model NO.:SLG65-III SLG70-II SLG85-II SLG95-II

- Product Name:Kellogg′s Corn Flakes Making Machine

- Function:Extrusion

- Final Product:Breakfast Cereals; Corn Flakes; Puffed Snacks

- Raw Materials:Corn Flour, Rice Flour, Wheat Flour etc

- Capacity:100-150kg,H; 200-250kg,H; 300-400kg,H

- Motor Brand:ABB, Siemens

- Inverter:ABB, Delta

- Machine Materials:Stainless Steel

- Transport Package:Wooden Package in Container

- Specification:Stainless Steel Food Grade Materials

- Trademark:Saibainuo

- Origin:China

- HS Code:84388000

- Production Capacity:50 Sets,Month

=== Description ===

Basic Info.

Model NO. SLG65-III SLG70-II SLG85-II SLG95-II Product Name Kellogg′s Corn Flakes Making Machine Function Extrusion Final Product Breakfast Cereals; Corn Flakes; Puffed Snacks Raw Materials Corn Flour, Rice Flour, Wheat Flour etc Capacity 100-150kg/H; 200-250kg/H; 300-400kg/H Motor Brand ABB/ Siemens Inverter ABB/ Delta Machine Materials Stainless Steel Transport Package Wooden Package in Container Specification Stainless Steel Food Grade Materials Trademark Saibainuo Origin China HS Code 84388000 Production Capacity 50 Sets/MonthProduct Description

New Technology Kelloggs Corn Flakes Making MachineTwin screw extruder for cereal breakfast corn flakes making machines adopts the extrusion technology. After the cereals is extruded, the products will become bigger, puffy texture, crisp taste, starch form, increasing the water dissolve, easy to absorb by human, thus, it is popular in the world.

Description of Corn Flakes Making Machine

Corn flakes/Breakfast cereal is a kind of crispy food, with the characteristics of hard to be steeped broken and strong grain taste. It is mainly made from corn flour and other grains powder. It can be used as a snack or served with milk and coffee.Change molds and choose the right process to produce circles, balls, sheets, stars, letters and other products,and produce core filling snack food, filling biscuit ,nutrition breakfast, corn flakes and other puffed foods.

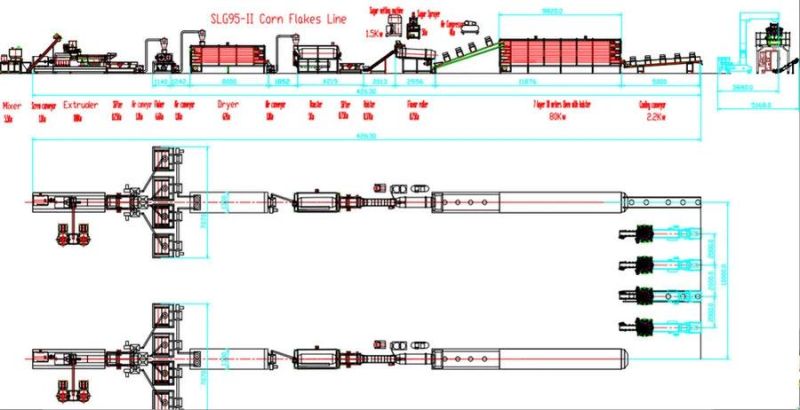

Corn Flakes Making Machine Production Line Flow Chart:

Raw material formulating → Mixing → Extruding → cooling conveying → Air conveying → tablet compressing → Drying → Flavoring → Conveying → Drying →Cooling conveying →(Packing)

Layout of Corn Flakes Making Machinery Process Line

We can design the whole breakfast cereals corn flakes machine processing line according to customers' factory size and structure.

Technical parameters of Corn Flakes Making Machinery:

| Model Parameters | SLG70 Corn Flakes Machine Processing Line | SLG85 Corn Flakes Machine Processing Line |

| Installed capacity | 166KVA | 263KVA |

| Power | 110Kw | 200Kw |

| Output | 200-250kg/h | 300-400kg/h |

| Dimension | 45×3×4m | 48.5×5×4m |

Breakfast Cereals Corn Flakes Pictures for Reference

This line can also produce different shapes breakfast cereals by changing the mould. We can also design the mould according to customers' requirement.

Corn Flakes Processing Machine Line in Workshop

Welcome you come to our factory for visiting. Our company is in Jinan City, Shandong Province, China.

If any need for our machines, please do not hesitate to contact with us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23