SUS316L Stainless Steel Shampoo Mixing Tank Soap Mixing Tank

Guangzhou Co-Dream Printing Co., Ltd. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:380V

- Composition:Stainless Steel Tank

- Processing Material:Liquid Beverage

- Process:Food Grade

=== Base Info ===

- Model NO.:RET-4033

- Material:SUS304 or SUS316L

- Application:Food

- Transport Package:Playwood Cases

- Specification:50L~2000L

- Trademark:RAYEN

- Origin:China

- HS Code:8479820090

- Production Capacity:100 Set,Month

=== Description ===

Basic Info.

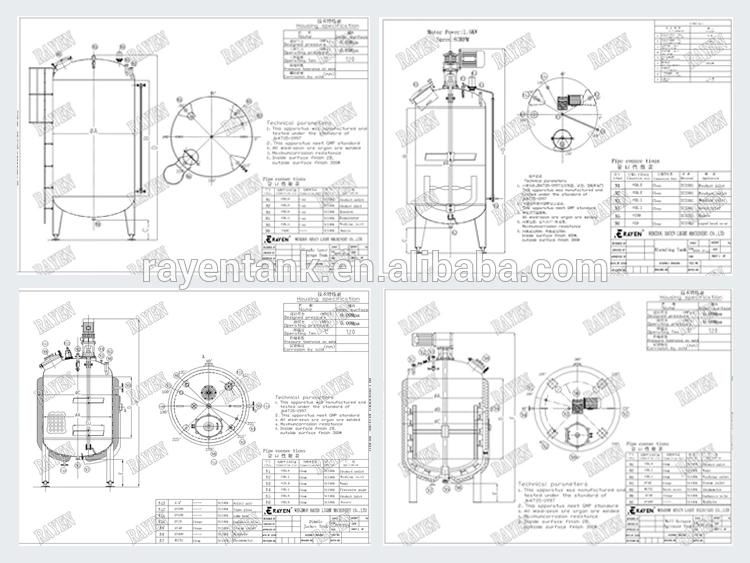

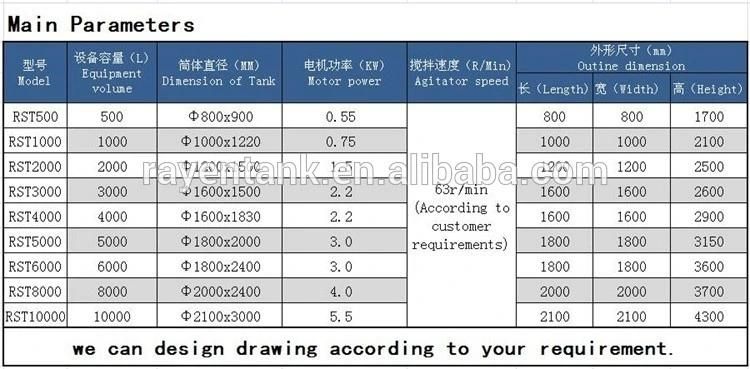

Model NO. RET-4033 Material SUS304 or SUS316L Application Food Transport Package Playwood Cases Specification 50L~2000L Trademark RAYEN Origin China HS Code 8479820090 Production Capacity 100 Set/MonthProduct Description

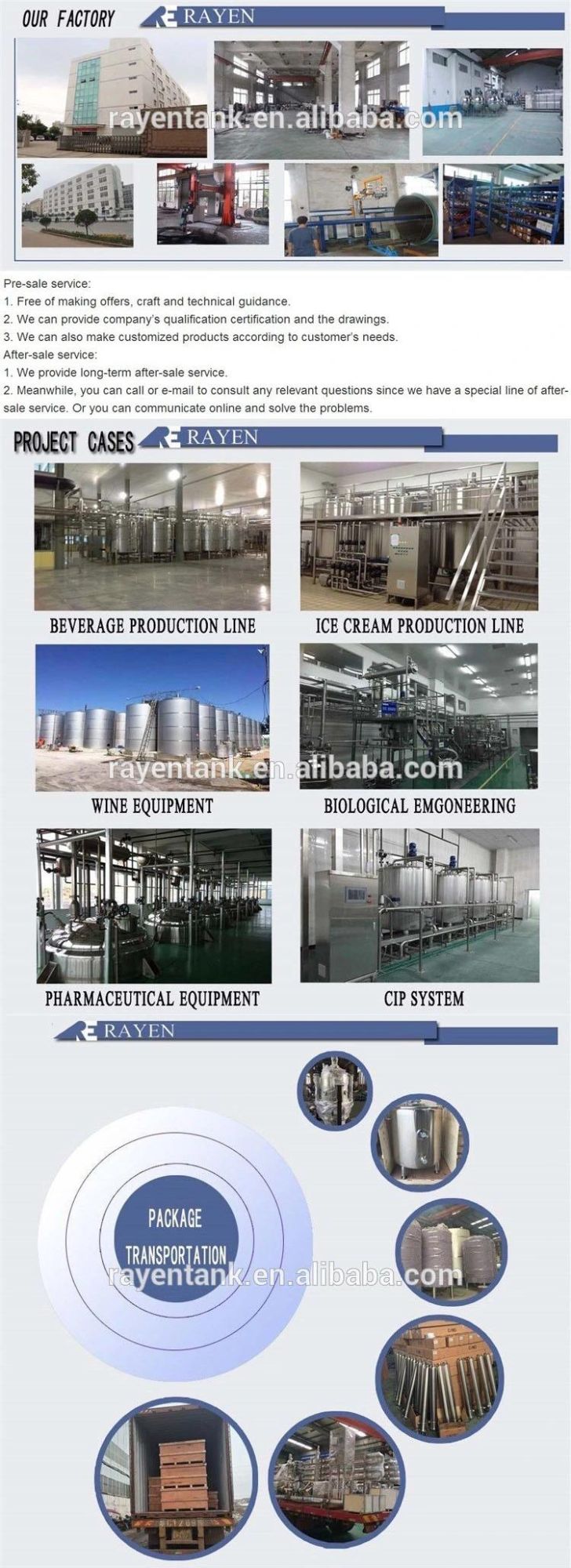

Made-in-China Leading Company TOP10 Supplier

SUS316L stainless steel shampoo mixing tank soap mixing tank

SUS316L stainless steel shampoo mixing tank soap mixing tank can be used as liquid storage tank, liquid mixing tank ,liquid heating or cooling tank and so on.It is suitable for food, dairy products, fruit juice beverage, pharmaceutical and chemical and biological engineering.

Finish:Mirror or Matt Polish; Ra<0.4um

1. Material:Stainless steel, austenitic stainless steel 304, 316L etc, with insulating material or not

2. Tank shell thickness:3mm at least (according to the design or your required)

3. Design work pressure (MPa):-0.1~~1.6MPa (According to the China national standard, breakthroughs in the foregoing measurements are allowed in special cases)

4. Design work temperature:-4~~+150C

5. General accessories(If required):Manhole, CIP, respirator, sight glass, mixing(Top side or bottom)

Certification: CE ISO9001:2000.

Have different kinds of agitators:

1, Bottom magnetic agitator with propeller impeller, speed from 50-400rpm or 50-800rpm. this kind of agitator is mixing thin viscosity , such as eyedrop, injection, CIP liquid, water, etc.

2, Top mechancial agitator with propeller impeller, speed at fix 71rpm or adjustable 20-200rpm or special requirement. this kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.

3, Top mechanical agitator with anchor or frame impeller, speed is from 10-70rpm. it is mixing higher viscosity , such as sediment or viscosity oral liquid, etc.

4, Top emusification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. this kind of agitator is mixing most high viscosity , such as suspension, oil, fat emulsification , etc.

5, Bottom emusification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. this kind of agitator is mixing most high viscosity , such as suspension, oil, fat emulsification , etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23