Cable Sheath Making Machine

Guangzhou City Anguli Import and Export Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Automation Automatic Computerized Computerized Certification CE, ISO9001:2008 Weight 7100kg Color White and Orange Producing OEM /ODM Energy-Saving Servo Motor Transport Package Whole Machine Specification 5.3*1.4*2.0 Trademark SENVO Origin Laiwu, China HS Code 8477101090 Production Capacity 600PCS/YearProduct Description

Product Introduction"SENVO" servo energy-saving injection molding machine combines the mature injection molding machine manufacturing experience of SENVO injection molding machine and configures the German Ike and Japanese Sumitomo oil pumps. The servo drive system is Monde and haimike system, which realizes the advantages of energy conservation, environmental protection, high repetition accuracy, reliability and durability. Let customers with the lowest cost in exchange for the largest profit, enhance competitiveness. SENVO provides ZS series servo energy-saving injection molding machine, which can choose the right model according to your needs.

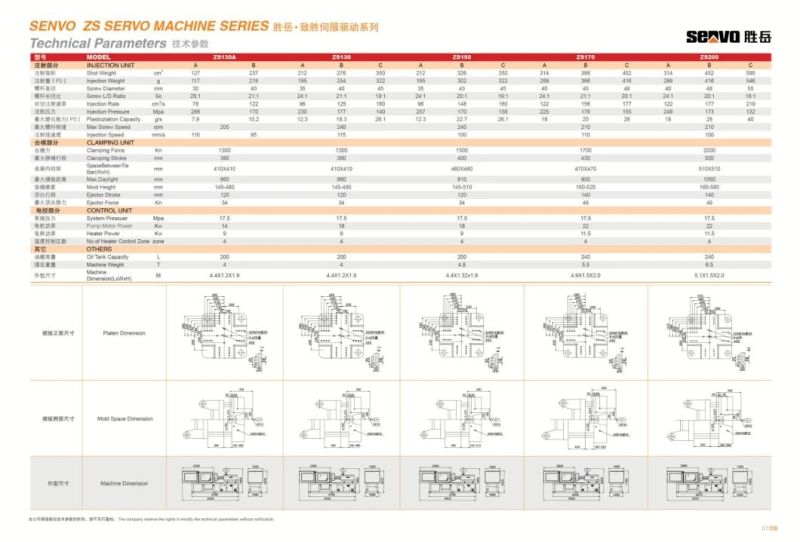

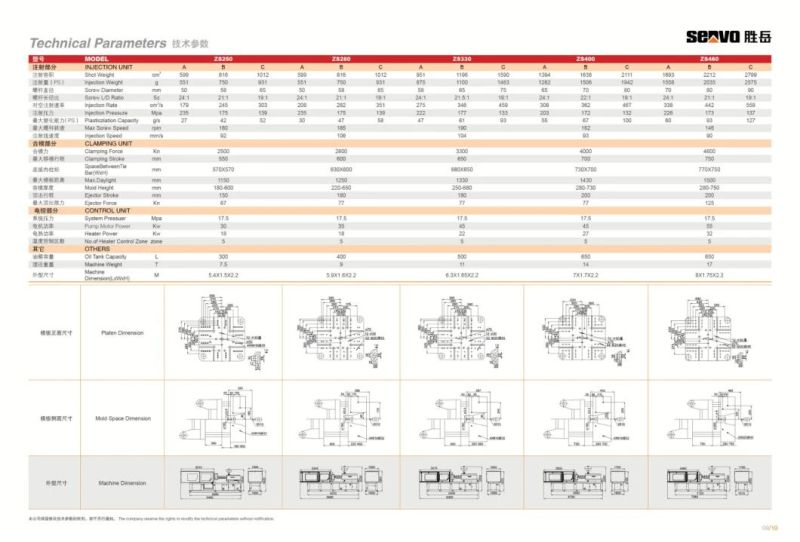

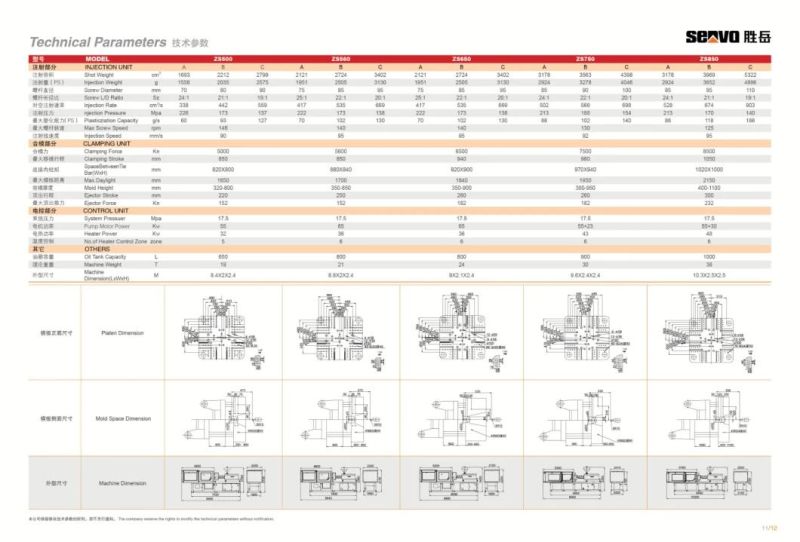

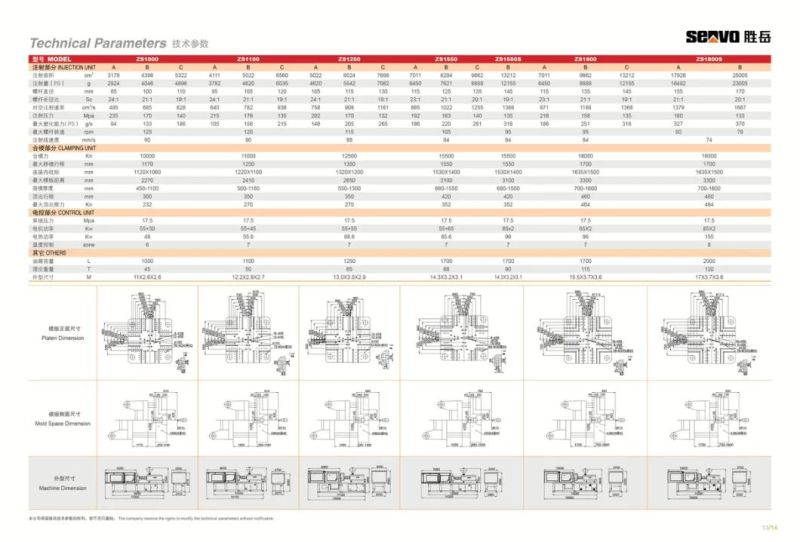

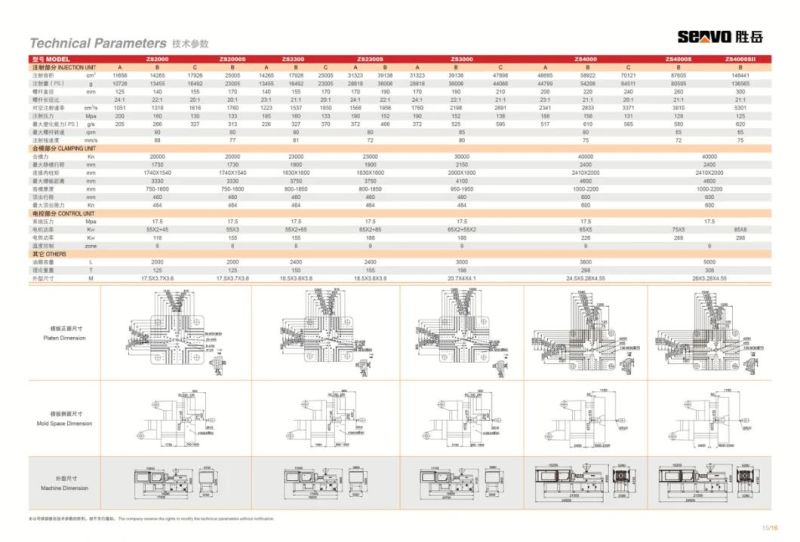

Technical parameters

Company Profile

Company Profile

Note:

1.Customers offer the place for the sets of machine ,factory offer the design for the sets of machine.

2.Payment:

30% as down payment to seller's account by T/T ,70% balanced after inspection and before shipping

3.Shipping date:

Within 30days after receiving the down payment

4.Installation and after-sale service:

The machine installation and debugging time should be within 5 days , before seller coming ,the buyer should keep everything ready.The warranty is 1 year ,within this term ,seller offer the easy-wearing parts to buyer for free ,and beyond this term ,seller offer a lowest price for the broken parts.For the installation and debugging workers from seller, the buyer should bear the cost for travelling, board and lodging ,and should pay 100USD/day for one worker .The training site is fixxed by two parties.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23