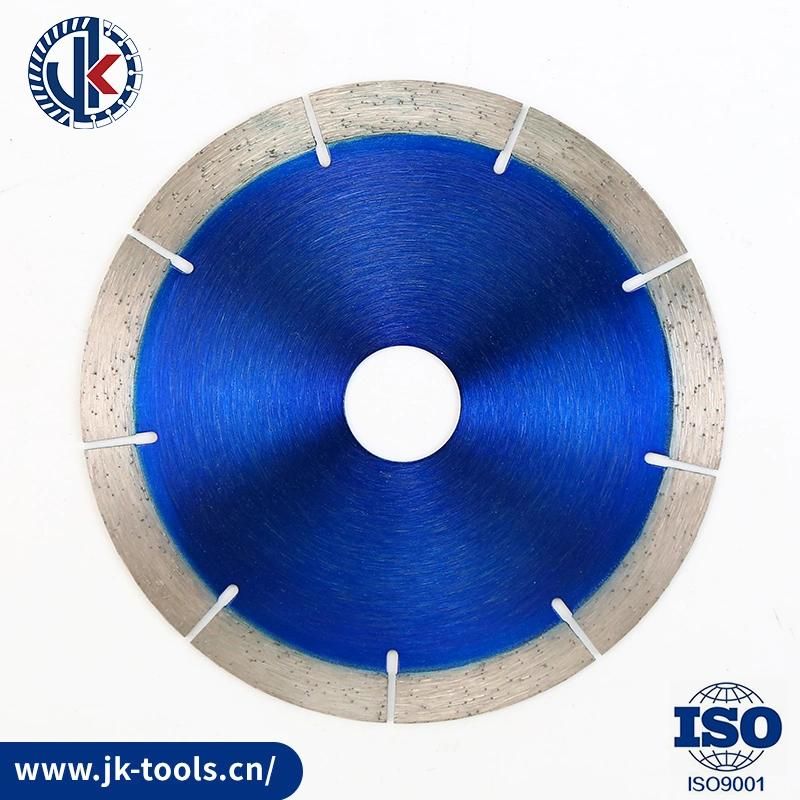

Made in China Hot Pressed Sintered Segmented Diamond Saw Blade for Cutting Stone Marble Ceramic Tiles Concrete

Ningbo Furuidi Packaging Products Co., Ltd. / 2022-06-27

- Blade Type:Granite Cutter

- Manufacturing Process:Hot Press

- Application:Stone

- Product Name:Diamond Saw Blade

- Type:Segmented Saw Blade

- Diameter:105,110,115,125,180mm,230mm

=== Base Info ===

- Model NO.:4-7′

- Technology:Hot Press

- Advantage:Fast Cutting and Durable

- Place of Origin:Hebei China

- Export Area:Global

- Package:Carton

- Payment Item:T,T

- Transport Package:Carton or Pallet

- Specification:105mm, 110mm, 115mm, 125mm, 180mm, 230mm

- Trademark:JK

- Origin:China

- HS Code:8202391000

- Production Capacity:50000PCS,Month

=== Description ===

Hot press sintered saw blade has high cost performance, used for cutting ceramics, ceramic tiles, vitrified bricks, microspar and other building decoration materials.

Hot press sintered saw blade has high cost performance, used for cutting ceramics, ceramic tiles, vitrified bricks, microspar and other building decoration materials.

Blades with special sector segments, very Suitable for fast and smooth cutting of granite, stone, Hard material.

Various formulations are available for different cutting applications. The products are suitable for processing all kinds of building materials, natural and artificial stone, etc.

105-230 mm saw blade suitable for Angle grinder; 230-350 mm saw blades are used for electric saws and gasoline saws.

Blades with special sector segments are ideal for fast and smooth cutting of granite, stone and hard materials.

It is specially designed for professional users to cut tiles in clean and chip free. Our range is outperform and outlast.

Segmented Diamond Saw Blades for Marble, Granite

(INCH)

(MM)

(MM)

(MM)

FAQ

FAQ

How to distinguish the diamond saw blade?

- observe the tool head exposed outside the emery, observe its concentration and distribution. Good diamond saw blade, the emery content is not too little, but also not too much, and evenly dispersed.

- observe whether the weld is complete and tidy. If the weld seam is not continuous, and the edge of the tool head is not vertically aligned with the matrix water tank, it will affect chip removal and heat dissipation. And it may cause the blade to fall off.

- the saw blade is held in the hand to observe whether the diamond cutter head is aligned with the matrix on the horizontal plane. If the cutter head is uneven and the canine teeth are staggered, it is likely to cause the plate edge chipping or even the cutter head falling off in the process of use.

- compare the thickness of the tool head and the thickness of the matrix. Taking 350mm granite saw blade as an example, under normal circumstances, the cutter head should be about 1mm thicker than the matrix. The blade of 350mm marble saw blade is about 0.2mm-0.5mm thicker than the base. The reason of this design is to avoid damage to the substrate and prolong the service life of the saw blade.

- the sharpness of the saw blade and wear resistance will have a contradictory relationship. Our recommendation is that when the blade life has reached the desired goal, and the sharpness is moderate, do not ask for increased life. Because the external environment, such as cutting machine, workers' operation, stone hardness and other conditions will change at any time, and once the external environment changes, the original wear-resistant saw blade may not be able to use.

Our company's philosophy: keep improving, customer first, only do the most professional diamond tools.

Welcome contact us and OEM orders to us ! we will be your best partner in China !

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23