Laser Paper Vacuum Aluminized Cardboard Laminating Coating Machine

Longgang Xinxin Printing Machinery Co., Ltd. / 2022-06-27

- After-sales Service:Factory Service

- Warranty:1 Year Warranty

- Type:Roll Coater

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Paper

=== Base Info ===

- Model NO.:znfh1300

- Packaging Type:Cartons

- Application:Electronics, PE, EVA, Paint, Fabric

- Transport Package:Plastic Around

- Specification:1200mm width

- Trademark:yueda

- Origin:China

- HS Code:8420100090

- Production Capacity:50sets,Year

=== Description ===

Basic Info.

Model NO. znfh1300 Packaging Type Cartons Application Electronics, PE, EVA, Paint, Fabric Transport Package Plastic Around Specification 1200mm width Trademark yueda Origin China HS Code 8420100090 Production Capacity 50sets/YearProduct Description

ZNFH1300 Film Cardboard Laminating Coating Machine

1. Description:

Gold and silver cardboard production equipment designed and manufactured to suit modern domestic gold and silver cardboard, laser materials, tobacco and wine packaging materials. The multifunctional machine with the functions of unwinding, gluing, coloring, hot air drying and winding is centralized controlled by imported PLC and controlled by touch screen. At present, the most perfect technology, the most complete function and the most advanced control technology in China are the ideal gold card paper composite equipment.

2. Main Technician Specification:

| 1 | Max.unwinding diameters | Φ1500mm |

| 2 | Laminating width | 600-1200mm |

| 3 | Paper core diameters | 3″,6″,12″ |

| 4 | Laminating Film Max.Diameter | 3″ |

| 5 | Film Unwinding Core | 3″ |

| 6 | Max.Diameter Rewinding Roller | φ1500mm |

| 7 | Rewinding Core | 12 |

| 8 | Roller Width | 1300mm |

| 9 | Paper thickness | 40~400gsm |

| 10 | Film material thickness | 0.001~0.06mm |

| 11 | Heating oven | 12.5mm |

| 12 | Max.speed | 120m/min |

| 13 | Total power | 112kw |

| 14 | Overall dimension | 22.5x2.8x3.2m |

3. Standard Equipment:

- Paper Unwinding Part(Shaft Less)

- Aluminum Foil/Bopp/Opp Film Unwinding Unit

- Glue Coating Unit

- Laminating Unit

- Color Coating Unit

- IR Heat Oven Unit

- Water Cooling Unit

- Rewinding Unit(Shaft Less)

| Name | QTY | Unit | Original Brand |

| Hydraulic System | 1 | set | TAIWAN |

| Unwinding Brake 10KG | 2 | pcs | CHINA |

| Edge Position | 1 | set | CHINA |

| Tension Controller 10KG | 1 | pcs | CHINA |

| Film Unwinding Tension | 1 | pcs | CHINA |

| Coating motor | 1 | pcs | CHINA |

| Coating Frequency 0.75KW | 1 | pcs | CHINA |

| Main Motor 3.0KW | 1 | pcs | CHINA |

| Main Frequency 3.7KW | 1 | pcs | CHINA |

| Scrap Motor | 1 | pcs | CHINA |

| Plate Roller Motor | 1 | pcs | CHINA |

| Plate Roller Frequency | 1 | pcs | CHINA |

| Color Pump(Air) | 1 | pcs | CHINA |

| Over-heating Motor | 4 | Pcs | CHINA |

| Oven Discard Motor | 1 | Pcs | CHINA |

| Back Cooling Motor | 1 | Pcs | CHINA |

| Back Tow Motor 3.0KW | 1 | Pcs | CHINA |

| Back Tow Frequency 3.7KW | 1 | Pcs | CHINA |

| Rewinding Motor5.5KW | 2 | Pcs | CHINA |

| Rewinding Frequency 5.5KW | 2 | Pcs | CHINA |

| Hydraulic Delivery System | 1 | Pcs | CHINA |

| PLC | 1 | Pcs | JAPAN |

| HIM 10Inch | 1 | Pcs | CHINA |

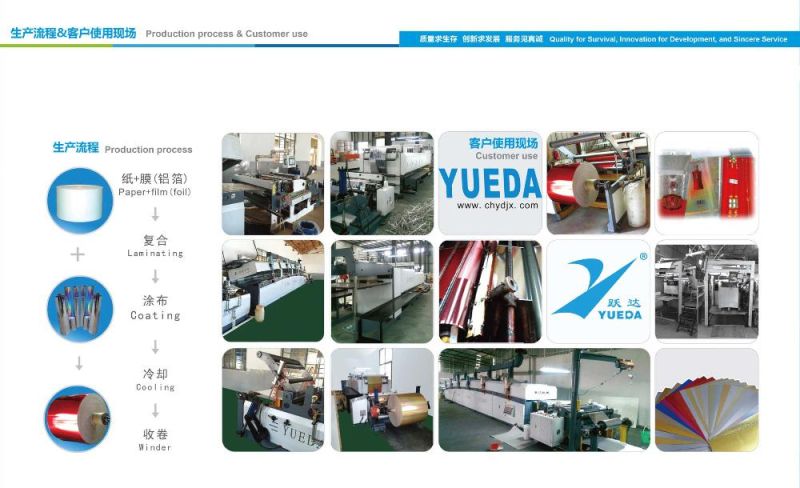

Machine photoes:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23