304 Stainless Steel Enrobed Chocolate Candy Bar Making Line

SHANTOU DAFU PLASTIC PRODUCTS FACTORY CO., LTD. / 2022-07-04

- After-sales Service:Online

- Warranty:1 Year

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:TPX200

- Application:Ice Cream, Candy, Chocolate, Chips, Biscuit

- Customized:Customized

- Single Roller Width(mm):200

- Flatten Roller Width(mm):200

- Conveyor Belt Width(mm):200

- Cooling Tunnel Effective Width(mm):200

- Linear Speed(M/Min):0-5

- Hopper Heating:3kw

- Material:304 Stainless Steel

- Transport Package:Container

- Specification:Customized

- Trademark:GUSU

- Origin:China

- HS Code:8438200000

- Production Capacity:12

=== Description ===

Basic Info.

Model NO. TPX200 Application Ice Cream, Candy, Chocolate, Chips, Biscuit Customized Customized Single Roller Width(mm) 200 Flatten Roller Width(mm) 200 Conveyor Belt Width(mm) 200 Cooling Tunnel Effective Width(mm) 200 Linear Speed(M/Min) 0-5 Hopper Heating 3kw Material 304 Stainless Steel Transport Package Container Specification Customized Trademark GUSU Origin China HS Code 8438200000 Production Capacity 12Product Description

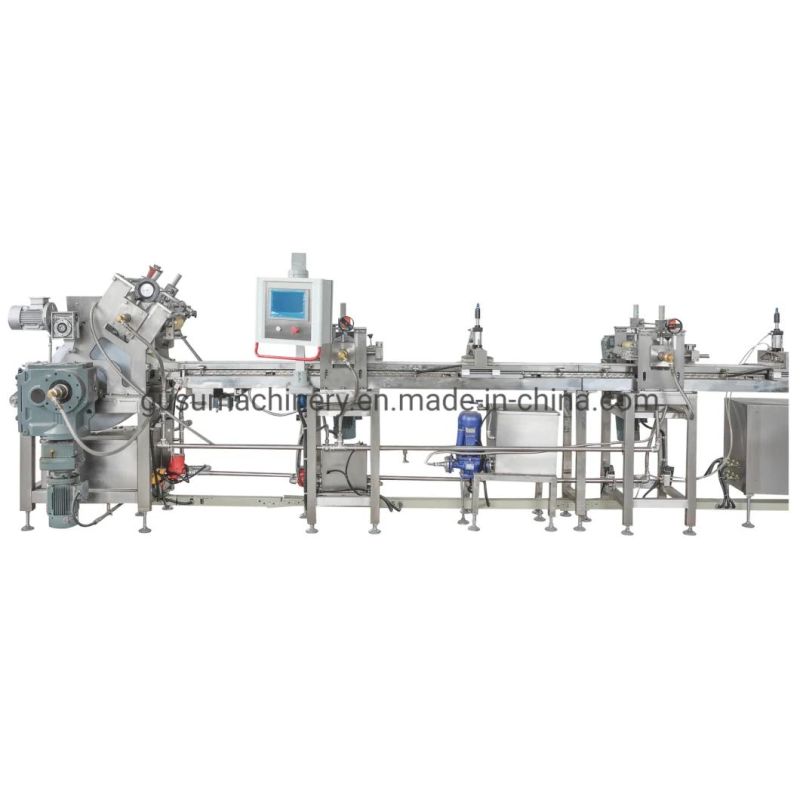

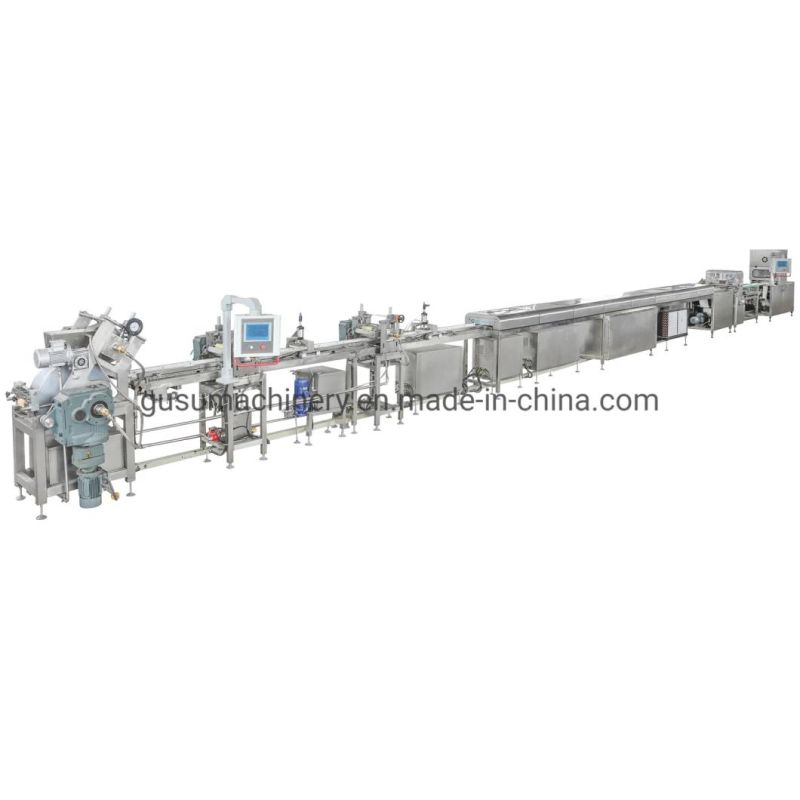

304 Stainless Steel Enrobed Chocolate Candy Bar Making Line

Product DescriptionCompound Candy Bar Automatic Forming Line is designed to meet the fast growing market demand for bar products like Snicker, Nougat, Cereal Bar, Grains Bar, Energy Bar, Fruit Bar, Protein Bar, etc.

This line is perfect for both candy bars and bar products intend for diet and nutritional markets. And can also be used to produce everything from nougat or toffee layers, with or without nuts, to granola bars, etc.

Details

Gusu Candy Bar Forming Line is available in four widths: 400, 600 and 800mm. All functions of the bar forming line are regulated by means of one or two PLC control cabinets which is very easy to operate and saves time. Option of incorporating a cooling tunnel for enhanced cooling of the product layers. High quality rollers designed to guarantee both precise forming and optimum cold transfer from the brine tank (Copeland Brand) to the product. The outstanding performance of the cooling equipment and system used for subsequent drying of product layers. Maximum efficiency and reliability and the option of varying cut dimensions, both in terms of length and width.

Technical Parameters

| Model | TPX200 | TPX400 | TPX600 | TPX800 |

| Single Roller Width(mm) | 200 | 400 | 600 | 800 |

| Compound Roller Width(mm) | 200 | 400 | 600 | 800 |

| Flatten Roller Width(mm) | 200 | 400 | 600 | 800 |

| Conveyor Belt Width(mm) | 200 | 400 | 600 | 800 |

| Cooling Tunnel Effective Width(mm) | 200 | 400 | 600 | 800 |

| Longitudinal Cutter | 1 Unit | 1 Unit | 1 Unit | 1 Unit |

| Latitudinal Cutter Width(mm) | 300 | 500 | 700 | 850 |

| Linear Speed(m/min) | 0-5 | 0-5 | 0-5 | 0-5 |

Components

- Compound Single Group Roller

- Compound Group Roller

- Particle Spreader

- Former Roller

- Cooling Tunnel

- Longitudinal Cutter

- Longitudinal Distribution

- Latitudinal Cutter

- Chocolate enrober(Selective)

Advantages

Modular machine that can be adapted for production of any product the market might require: Energy Bar, Cereal Bar, Granola Bar, Protein Bar, Fruit Bar, Nougat, etc.

GUSU roller formers allow:

-direct feed from the cooking plant or the mixer without the need for interim cooling

-cooling and moulding in a single machine

-gentle moulding without pressure, without changing the weight or structure of the mass

-easy changeover between products or changes to the product mass.

Products Pictures

RAQ

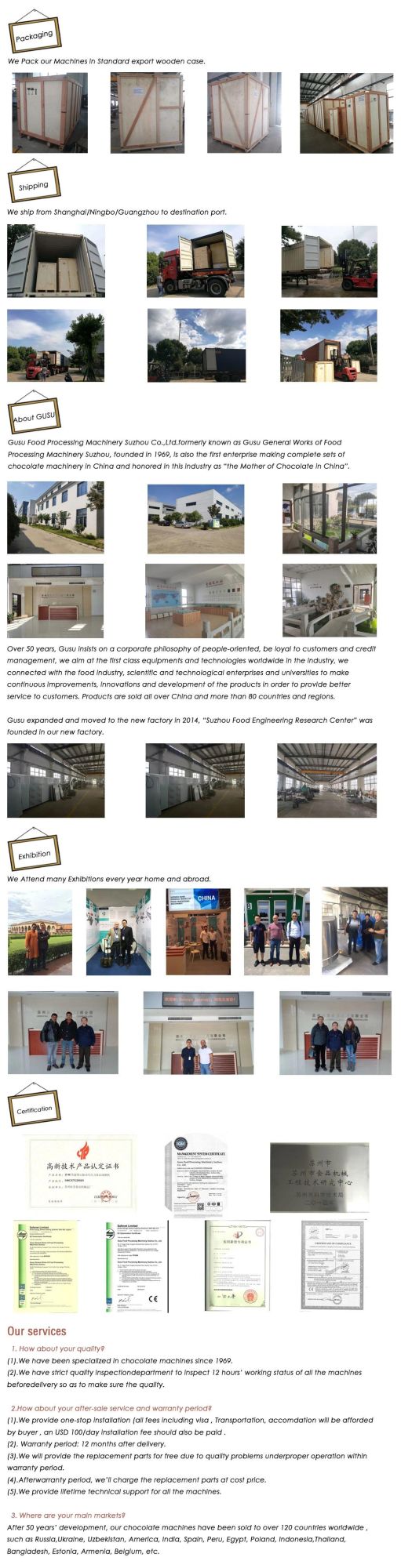

1 How to Order

1. Customer send us an inquiry.

2. Confirm machine type, order quantity, price, lead time, payment term etc.

3.Our sales send the Proforma Invoice with company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5. Inform the clients that we have got the payment,and will arrange the production according to yourrequest, inform the estimated time

6. Production products photos will send to you for approval.

7. Clients make payment for balance and Ship the goods .

8. Order is finished when you receive the goods and satisfy with them .

9. Feedback to us about Quality , Service, Market Feedback & Suggestion.And we can do better

2 About after-sell service

Usually machine guarantee time is about 1 year . Within guarantee time . Machine breaking caused bymachine itself design defect , we are responsible for it .we can provided free charge breaking part .If machine breaking caused by humane factor , user need take responsibility for it , we will providedtechnical support .

3 About goods shipping

We have long time working shipping forwarder. We can do our best to send machine to your port safe and quickly.

4 About our online Service

24 hours online to solve any problem .

Your email will be reply within 12 hours .

Your satisfy is our pursuit .sincerely hope our cooperation.

Contact us

Contact person:Bob Shi

Website: gusumachinery.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23