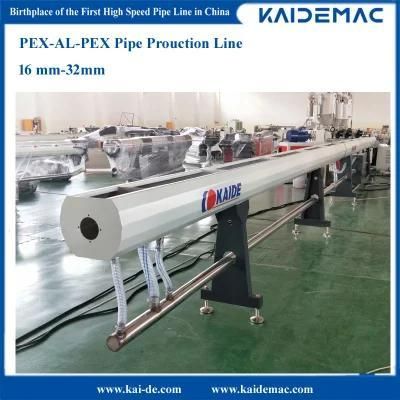

Overlapped Welding Pex-Al-Pex Pipe Production Line

Nanjing Lite Hydraulic Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. pex al pex pipe line Condition New Pipe Diameter 16mm-32mm,16mm-63mm Production Line Length 31mx3.5mx3.0m Inverter ABB Brand Electrics Schneider Computer Siemens Engineer Service Engineer Is Available for Overseas Service Line Speed 3m/Min-9m/Min Warranty Time One Year Pipe Standard ASTM1282 Exported Countries Algeria, Ukraine, Russia, Iran, Jordan, Korea,,, Transport Package 1X40 Gp Container, 8tons Specification SJ50/33, SJ45/30, inner die head, outer die head Trademark KAIDE Origin China HS Code 8477800000 Production Capacity 200 Sets Per YearProduct Description

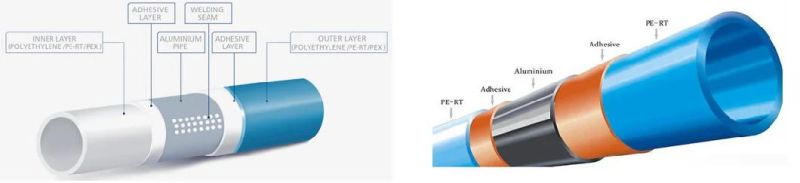

Ultrasonic Overlap Welding AL-Plastic Composite Pipe Line, The Al-Plastics Overlapped Welding machine including below lines: PEX-AL-PEX Pipe Line, PERT-AL-PERT Pipe Line, PPR-AL-PPR Pipe Line,PE-AL-PE Pipe Line.

Technical Data

| Line Model | Extruder Model | L/D | Production Scope | Production Speed | Nominal Power |

| SJ-45 | SJ-45/45/30 | 30/25/25:1 | Ф16-32mm | 8-9m/min | 93KW |

| SJ-65 | SJ- 65/65/30 | 33/33/25:1 | Ф16-63mm | 8-9m/min | 154KW |

High Efficient Extruder

(1) This high efficient extruder of this Al-plastic composite pipe line is specially independently designed by KAIDE company.

Consists of :

(2) Inner Plastic Layer Extruder, Inner Glue Layer Extuer, Outer Plastic Layer Extruder, Outer Glue Layer Extruder

Ultrasonic Overlap Welder

(1) The Aluminum pipe is formed by ultrasonic overlapped welding. It uses high quality and well-known brand welder, with even welding seam and good quality.

Aluminum pipe forming moulds

(1)The technology has been further developed based on original production machine technology.

(2)The Aluminum pipe forming molds and co-extrusion die head molds have been optimized and manufactured by imported high precise CNC machine, which have greatly increased the pipe forming accuracy and production speed.

PLC control system of pex al pex pipe machine

The five layers aluminum plastic pipe line adopts original Siemens new generation PLC control system with full color screen, which ensures the high speed synchronous control and reliable operating of the whole production line.

(1) It is easy to install and can be buried in walls and concrete. With a simple metal detector, the installation can be detected. Therefore, the pipe is very suitable for cold and hot water pipeline system in industrial and civil buildings.

(2)Indoor gas pipeline system,The longitudinally welded aluminum pipe is clamped in the middle of the plastic, so that the universal pipe can withstand a higher working pressure, so that the gas (oxygen) permeability is zero, and the length of the pipe can reduce the joints and avoid leakage. Therefore, this kind of pipe is safe and reliable for compressed air, gas, oxygen and other gas transmission lines.

(3) Solar air conditioning piping system.Aluminum plastic composite pipe is not easy to frost, good insulation, improve the efficiency of solar energy and air conditioning system

Kaide Plastics Machinery Co.,ltd has more than 20 years' experience of plastics pipe extrusion machinery, especially for high speed pipe production line and composite pipe production line.

Kaide Plastics Machinery Co.,ltd has more than 20 years' experience of plastics pipe extrusion machinery, especially for high speed pipe production line and composite pipe production line.Our main products are:

Flat drip irrigation tape line,Round Drip Irrigation pipe machine

PPR/PERT/HDPE pipe line,Glassfiber PPR Pipe Line,PPR-AL-PPR pipe line,PEX-AL-PEX pipe machine,PERT-AL-PERT pipe machine,Mulilayer Al-plastic pipe production line,Multi-layer EVOH/PERT/PEXA/PEXB pipe line,PB pipe production line,PPR pipe machine, Medical catheter line,etc .

(1) The machinery have been exported to many countries, such as: Russia, USA, Korea, Algeria, Egypt, Iran, Japan, Kyrghyzstan, Cyprus, Morocco, Ukraine, Mexico, Estonia, Saudi arabia, Uzbekistan, etc,which has gained high reputation from the customers.

(2)Professional R&D team,which are continuously concentrating on optimizing of our technology to keep the leading position. Several technologies have obtained nationalinvention patent & utility model patent;The Whole process of machine manufacturing is under good quality control.

(3)From raw material purchasing, to components manufacturing, thento test running of the line, each process we have strict quality requst, to ensure that a high quality product will be delivered to the customer; We cooperate with well-known enterprises for some mechanical parts, such as: ABB, Siemens, Schneider,Autonics, SMC,Delta,ORMON,Eurotherm,PAKER, etc.

(4)We are located in Weifang, Shangdong Province, near to Qingdao city,warmly welcome to visit our factory, here is two hours away from Shanghai, one hours away from Beijing, three hours away from Guangzhou.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23