Chocolate Tempering Equipment Automatic Chocolate Tempering Machine

Hubei Hawking Packaging Material Co., Ltd. / 2022-07-05

- Certification:CE

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Chocolate

- Customized:Non-Customized

=== Base Info ===

- Model NO.:DR-QT

- Chocolate Making Machine:Chocolate Temper

- Flow Rate(Kgs/H):100~250

- Screw Speed(Rpm):48

- Refrigeration Unit:3HP Copeland

- Total Power(Kw):8.3

- Dimensions(mm):1000×850×1900

- Transport Package:Wooden Case

- Specification:CE

- Trademark:D&R

- Origin:China

- HS Code:8438200000

- Production Capacity:50sets,Year

=== Description ===

Specification

Chocolate temper machine is designed according to the characteristics of the

natural cocoa butter and cocoa butter equivalent(CBE).

It is in a vertical structure, the chocolate mass is fed from the side, then go up

through the ten plates and output from the top of the machine. The tank is divided

into four temperature sections with 10 plates. After this process, the chocolate paste

will be crystallized well with a smooth taste, shine surface and longer shelf life.

The material of the main parts for stainless steel tempering machines:

1. ten plates are stainless steel 304

2. impellers are copper

3. cover and mainframe is stainless steel 304

4. principal axis will be stainless steel 304

5. heating water tank is stainless steel 304

6. Compressor to be Copeland brand water-cooled (made in China)

7. Motor and reducer is SEW(made in China), electric components are Schneider

or Siemens. PLC with the touch screen is Siemens. The water pump is Grundfos,

the temperature controller is Omron.

Detailed Images:

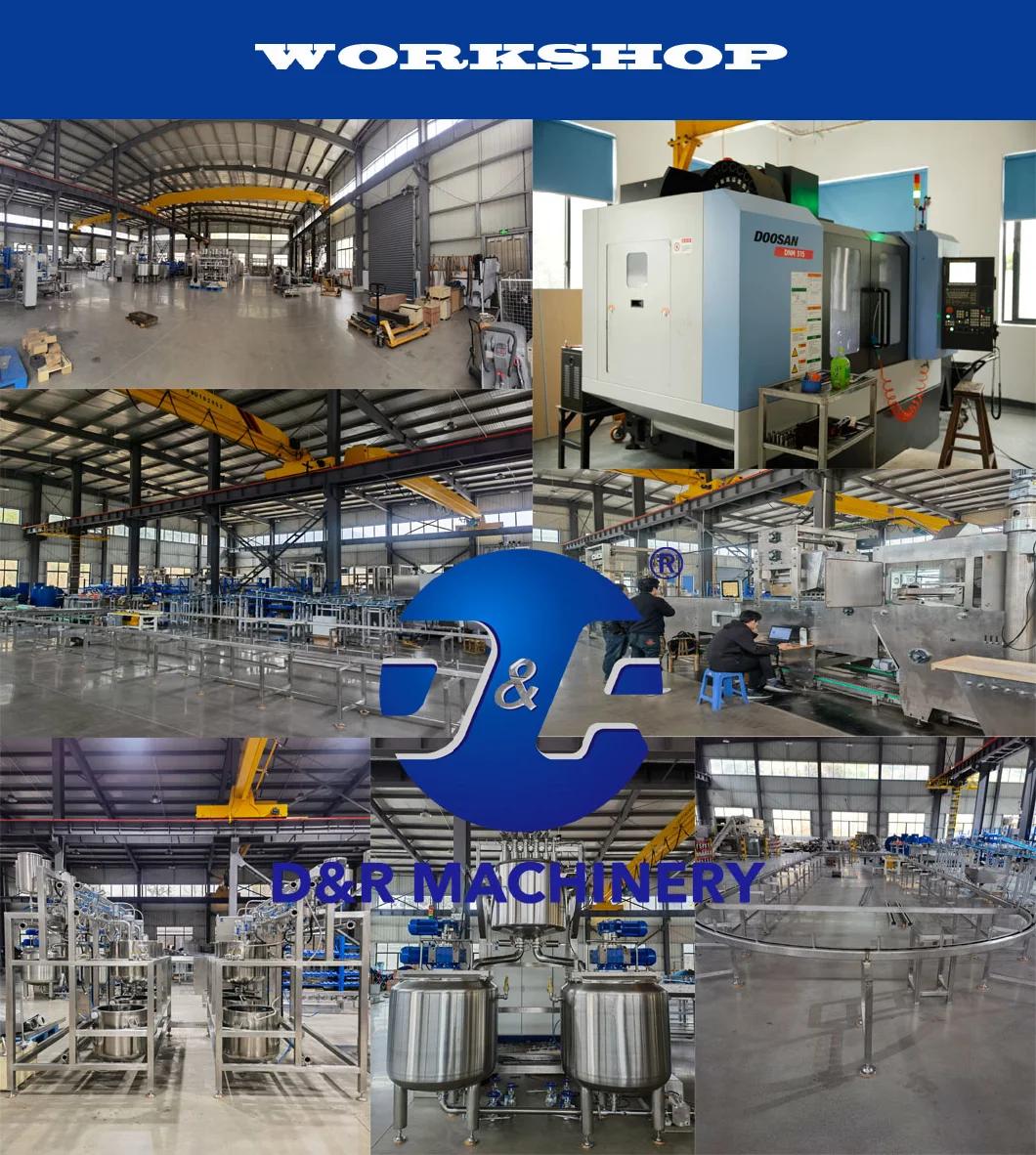

Company Introduction:

TOTAL SOLUTION ,TOTAL CARE

D&R Machinery are professional confectionery machine manufacturers with over 10 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23