Sunflower Seed Shelling Hulling Line

Shenzhen Xinhui Plastic Products Co., Ltd. / 2022-07-05

- Type:Grain Coarse Cereals Processing Equipment

- Application:Flour, All, Beans, sunflower

- Voltage:Customized

- Appearance:Horizontal

- Condition:New

- Customized:Customized

=== Base Info ===

- Model NO.:t

- Transport:by Sea

- Installation method:assembly

- Transport Package:Wooden Box

- Specification:combine

- Trademark:COYO

- Origin:China

- Production Capacity:50000PCS,Year

=== Description ===

Basic Info.

Model NO. t Transport by Sea Installation method assembly Transport Package Wooden Box Specification combine Trademark COYO Origin China Production Capacity 50000PCS/YearProduct Description

1. Product Description

In view of the special requirements of sunflower seed shelling, our company has developed a sunflower seed shelling and seed shell separation equipment. The production line adopts a unique double sheller setting, and realizes the separate control of the sheller through frequency conversion technology. It can remove all kinds of impurities in the raw materials of sunflower seeds, and shelling, peeling, sorting and classification of sunflower seeds. The unique wind return system can automatically return the unshelled seeds to the sheller for secondary shelling, thus greatly improving the shelling efficiency.

The machine has the characteristics of low broken generation, good shelling and separation effect, high automation and easy operation and maintenance. It is the best equipment for sunflower shelling and separation in the world. The processed sunflower kernel can be used in food industry and oil pressing industry.

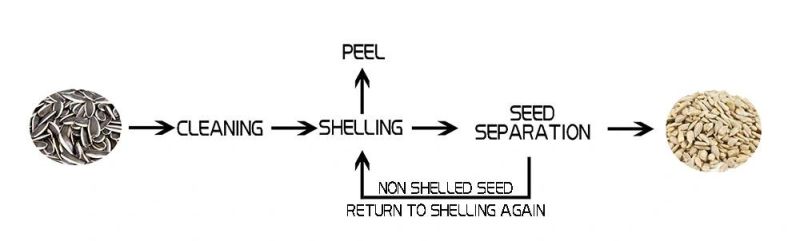

2. Processing Flow Chart

1,Feeding hopper, ,2,aw material elevator, 3,multi-function impurity remover (cleaner),,4,bucket elevator,,5,double sheller,6,Classifier (3 sets), 7,receiving hopper,8,wind return system, 9,control cabinet

Feature:

-The multi-functional impurity remover (cleaner) can remove large impurities, small impurities, light impurities, side-by-side impurities and other impurities (such as stone, glass, shrivel, hair, etc.) in raw materials

- All steel core and 99% high alumina ceramic blade are used in the sheller, which enhances the shelling effect and service life.

- Wind return system returns raw materials which is not shelled to sheller for shelling again

- The adoption of screw unloader facilitates the collection of sunflower skin and reduces the generation of dust.

-The application of the fish-scale screen can easily realize the separation of seed and kernel; the screen piece is made of high-quality cold-rolled -steel plate, strong and durable.

-The whole set of equipment is centrally controlled by the electric control cabinet, and the operation is simple and intuitive. The frequency of the sheller can be adjusted at any time according to the material conditions by adopting the frequency conversion design.

- The vibration source of the whole set of equipment is in the form of vibration motor, so the equipment installation is convenient and fast without foundation.

3. Technical Parameter

TKSF-100 model sunflower seeds de-hulling and separation production line

Flow chart:

Feeding hopper → raw material elevator→ multi-function impurity remover (cleaner), → bucket elevator → double sheller→ Classifier (3 sets) → receiving hopper→ wind return system→ Color sorter (option)→ Packing (option).

Technical Parameter

Total Power:15 KW

Capacity:0.5-1.0t/h (depend on raw material status)

Full kernel rate:≥90%

Un-hulled seed % in final:≤2-5%

Area required for production line:Length 15M; Width 3M; Height 4.5M

Total weight of this production line equipments: about 5Tons

TKSF-150 model sunflower seeds de-hulling and separation production line

Flow chart:

Feeding hopper → raw material elevator→ multi-function impurity remover (cleaner), → bucket elevator → sheller (4sets) → Classifier (3 sets) → receiving hopper→ wind return system → Color sorter (option)→ Packing (option)

Technical Parameter

Total Power:16.5 KW

Capacity:1.0-1.2t/h (depend on raw material status)

Full kernel rate:≥90%

Un-hulled seed % in final:≤2-5%

Area required for production line:Length 12M; Width 3.5M; Height 5M

Total weight of this production line equipments: about 5.5Tons

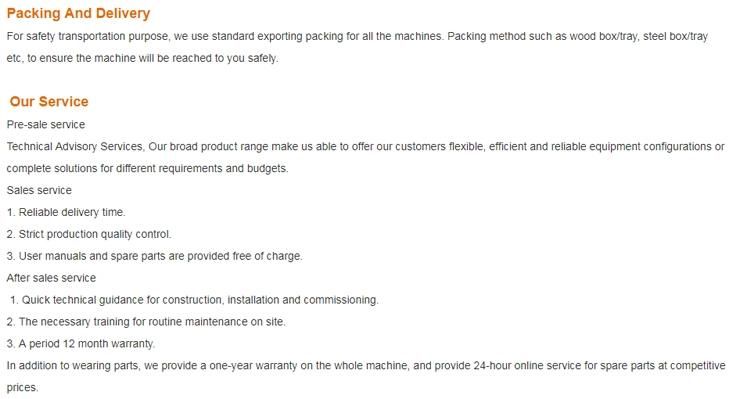

5. Sunflower Seed Hulling Show

6. Packing And Delivery

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23