Popular Ice Cream Making Machine

SHANDONG CORRUONE NEW MATERIAL CO., LTD. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Frozen and Chilled

- Automatic Grade:Automatic

- Application:Ice Cream

- Customized:Customized

=== Base Info ===

- Model NO.:KY-400

- Capacity:90-120PCS,Min

- Total Power:15kw

- Dimension:10000*2600*2880mm

- Weight:9000kgs

- Certificate:Ce&ISO9001

- Delivery Time:30days

- After-Sales Service:Instruction of Installation and Commission

- Material of Machine:Stainless Steel 304

- Voltage:380V,50Hz

- Free Mold:One Set

- Transport Package:Wooden Case

- Specification:customized

- Trademark:KEYFOOD

- Origin:Shanghai, China

- Production Capacity:200sets,Year

=== Description ===

Basic Info.

Model NO. KY-400 Capacity 90-120PCS/Min Total Power 15kw Dimension 10000*2600*2880mm Weight 9000kgs Certificate Ce&ISO9001 Delivery Time 30days After-Sales Service Instruction of Installation and Commission Material of Machine Stainless Steel 304 Voltage 380V,50Hz Free Mold One Set Transport Package Wooden Case Specification customized Trademark KEYFOOD Origin Shanghai, China Production Capacity 200sets/YearProduct Description

Automatic ice cream with stick production linePart 1 Application

The ice cream production can produce cup package, egg tray package, ice cream stick ,chocolate coating ice cream ,nut ice cream ,ice-cream stick etc products.

This production line is the automatic model, which can finish automatically from feeding to finished product

Electrical equipment art controlled in a centralized way, which doesn't need steam boiler and other coolingequipment

This production line can produce kinds of ice cream, such as cup ice cream,egg-tray ice cream,stick ice cream,chocolate coated ice cream,kernel ice cream and ice sucker, etc, by only changing the filling equipment.

Part 2 Production flow :

1) Flow chart : Raw materials mixing---> materials blendering--->Boiling--->cooling--->

Homogeneity--->Congelation--->Forming--->Packaging--->into refrigerator .

2) The whole ice cream production line consists of the following units:

1.Water treatment system

2.Mixing and Sugar Melting Tank

3.Pasteurizer and Homogenizer

4.Aging tanks

5.Freezer and filling unit

6.CIP cleaning system

7.After treatment equipment ,like conveyor,package or pallet etc

8.There are other assisant equipments used such as steam boilders,air compressor,cold water unit etc;

3 )Features: compact structure, small land area, High heat recovery, good effect of energy-saving and consumption reduction as well as simple operation.

4) Advance of automatic filling machine

1) High-degree automation, easy operation ,which can finish mixing ,sterilization ,homogeneity,aging,congelation ,filling etc steps, operation panel can be controlled by electronics.2) Develop new convenient material processing system ,which can put fruit and vegetable into high shear homogenizer, incorporate mixing ,dividing, crushing, homogeneity as a whole ,good stability, puffing rate can reach 100%.which made taste fine and smooth.

3) Two parts of cooling ,save energy ,reasonable distribution, reduce the load of refrigerator unit.

4) Continuous congelation to ensure quality by adopting imported cooling spare parts and frequency speed regulation.

5) Various kinds of forms by changing filling device ;

The ice cream quick-freeze tunnel suits mass production kinds of ice cream products in cold food industry.

This production line not only can make kinds of various ice cream, the cone garland ice cream, double ice cream, flat knitting rotating ice cream, cake ice cream etc, .but also can coat the ice cream with stick with chocolate.

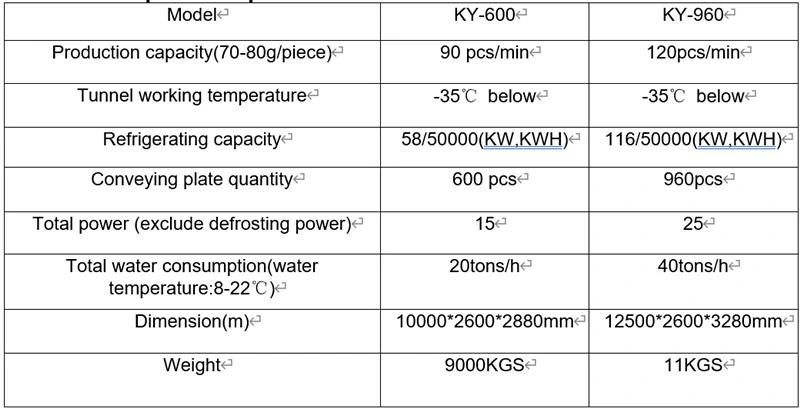

Part 3 Technical parameters

Part 4 Delivery pictures :

Part 5 Final products sample

For more detailes ,please feel free to contact us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23