Professional Manufacture WPC PVC Wall Panel Plastic Extruder Machine Extrusion Line

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

150-240 kg/h

PVC ceiling and PVC wall panel making machine details1,Main extruder

Extruder type: Conical double screw extruder

Model: SJMS51/105,SJMS 65/132

Motor: 22KW/37kw

feeder: Auto feeding

2,Mold for PVC ceiling profile /PVC wall panelDie head: one set

calibrators: three pieces

Mold heating: one set four pieces

water tank: one piece

3,Cooling and calibranting machineCooling type: vacuum cooling and water cooling

Cooling machine length: 6 meters

water pump: 1 set

vacuum pump: 1 set

4,Haul off machineDouble cater pillar: rubber cater pillar

Power: 2.2kw

Window glass: moveable

5,Cutting machineCutting power: 1.1kw

Cutting by automatical control

Length fixed as required, adjustable

PVC ceiling making process

1,Raw material mixer

Function:Mixing all raw materials together by hot mixer and so then can compound well,then cooling by the cold mixer prevent reaction.

Working process:Automatic loading feeder--6-10min hot mixing--10-15min cooling

In order to avoid pollution, the mixer needs to be alone in a room. In addition, the mixed raw materials can be stored in silos, then transported directly from the silo to the extruder.

2,PVC ceiling profiles extrusion line

Function and working process:

Automatic loading ----Conical double screw extruder ---die mould---calibrator platform cooling----haul off device---Automatic cutting machine---Productus stacker

Special design screw for PVC powder extrusion,SIEMENS brand motor,famous brand gear box,with automatic loading and feeder

In order to cooling the products well,adopt the cauum pump and water pump,two sets water tank.All parts contact with water are made by stainless steell.

The haul off device clamped the products by the rubber block, then the movement of the rubber block pulls the product forward.

Automatic cutting machine can customized cut the final products at the required length .

It has the functions of measuring cutting and accumulative counting.It adopt with the dust collector avoid pollution.

Carry and support the cutted final product, and then arrange neatly.

Made of stainless steel, the slide rail is equipped with a rubber protective layer.

3,PVC ceiling profiles mould

We can design the mold according your requirments,mould material: 3cr17,the special high-quality mold steel

We offer the mold for 60 /65/80/85 series PVC window and doors,the co-extrusion type for ASA surface and sealing rubber.

4,PVC ceiling surface treatment machine

Ceiling surface treatment mainly includes three types: film coating, rolling coating and spraying, among which the film-coated board is the best.

The surface treatment and process of the film-covered board are the same as the pre-coated board, except that the surface of the film-covered board is (PVC film). The surface of the film-covered board is adhered firmly, without wrinkles, scratches, or falling off.

5,SWP360 Plastic crusher

The crusher used to recycling the waste products ,then cutting them into small flakes.

6,SMW-500 high speed PVC Grinding machine

The high speed PVC grinding machine used to milling the PVC flakes into powder,so the waste PVC products can be recycled use.

7,20HP Water chiller :HANGKANG ANGES brand, compressor

Cooling the recycle water which used to cooling the products,

so it can increace the production speed and get good products surface.

8,30A air compressor

Provide the air to the mold,cylinder for haul off device,cutter,and stacker

Be Our Client:

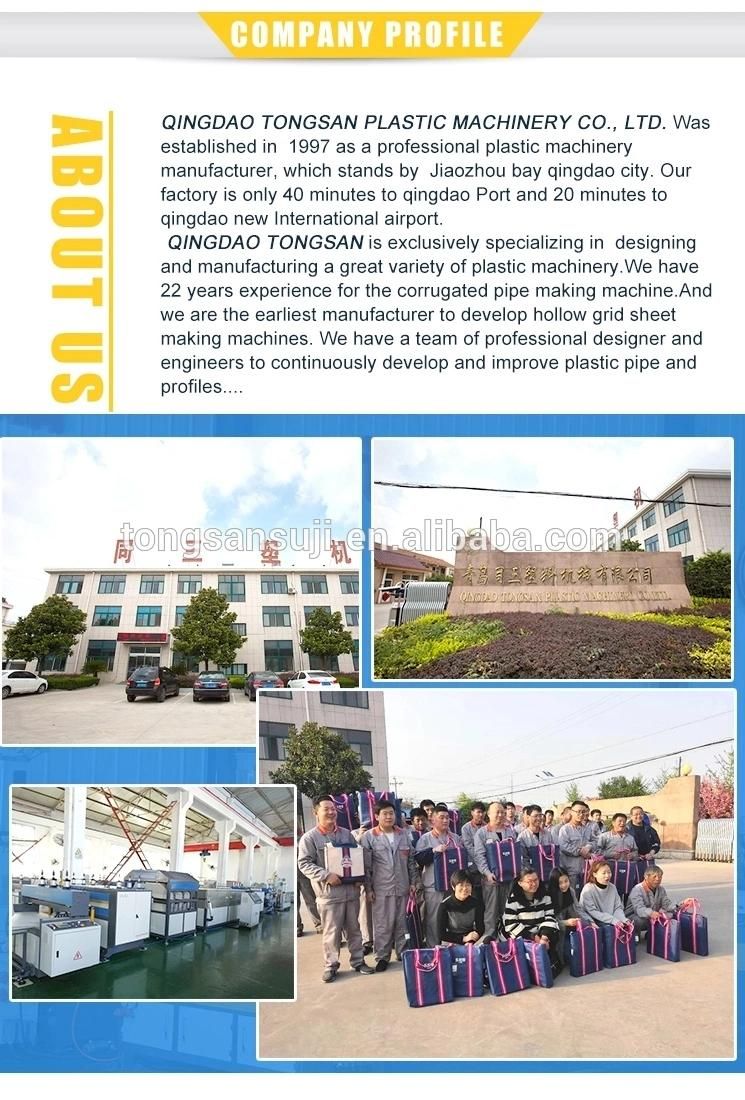

Why Choose Us?

FAQ:

More questions please send the massage to me.^-^

Looking for hear from you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23