Four Stage Fe Hydraulic Cylinder for End Tippers

ZHEJIANG MAYEN PACKING CO., LTD. / 2022-06-27

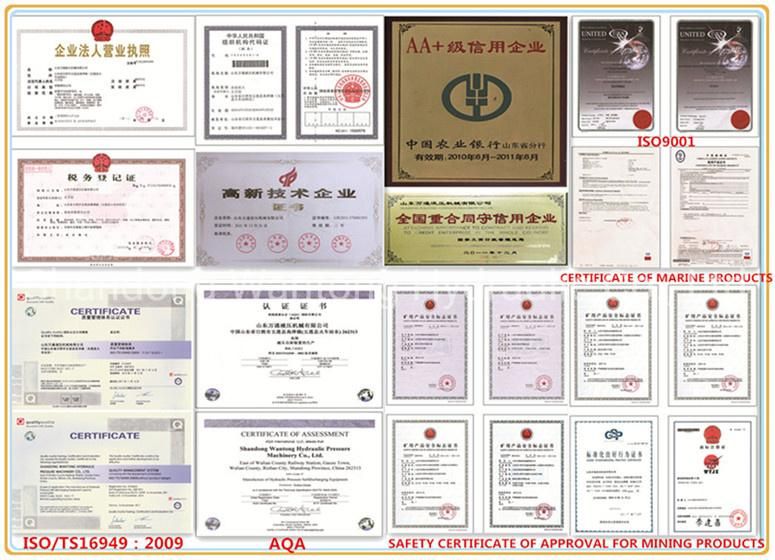

- Certification:RoHS, CE, ISO9001, Ts16949

- Pressure:Medium Pressure

- Work Temperature:Normal Temperature

- Acting Way:Single Acting

- Working Method:Straight Trip

- Material:Steel

=== Base Info ===

- Model NO.:FE-4-169-5180

- Name:Hydraulic Cylinder

- Working Pressure:16MPa

- Color:According to Your Requirements

- Certificate:ISO,Ts16949,ABS,API

- Delivery Time:20 Days

- Transport Package:Wooden Box or as Customer′s Requirement

- Specification:CE

- Trademark:WTJX , OEM

- Origin:Rizhao, Shandong

- HS Code:8412210000

- Production Capacity:200, 000 Sets

=== Description ===

Basic Info.

Model NO. FE-4-169-5180 Name Hydraulic Cylinder Working Pressure 16MPa Color According to Your Requirements Certificate ISO/Ts16949,ABS,API Delivery Time 20 Days Transport Package Wooden Box or as Customer′s Requirement Specification CE Trademark WTJX / OEM Origin Rizhao, Shandong HS Code 8412210000 Production Capacity 200, 000 SetsProduct Description

Four Stage FE Hydraulic Cylinder for End Tippers

Company profile

*History: 22 Years of history,the registered capital of 60 million yuan

*Scale: 180000 square meters,with 500 employees

*Capacity:Annual production of more than 200,000 sets

*Equipment:700set ,invested a large amount of money in introducing one electroplating production line.

*Certificate:ISO9001,ISO/TS16949,ABS,AQA etc

*Delivery time:20 Days

*Service:52 Service Outlets nationwide,24-hour Service

*Accept Custom

Products diameter:

| Cylinder Tube O.D. | 131mm-242mm |

| Operating Pressure | 16Mpa-20Mpa |

| Numbers of Stage | 3, 4, 5, 6 |

| Largest Moving Stage Diameter | 110mm-214mm |

| Stroke | 2900mm-9030mm |

| Closed Length | 1320mm-2177mm |

| Extended Length | 4220mm-11207mm |

| Plunger Mount Thickness | 42mm-52mm |

| Warranty Period | 14 months after date of production |

| Piston Rod Head RADIUS | 53-62mm |

| Oil port | G1/1''SAE |

| Hinge Shaft | 60mm-65mm |

| Hole size | 50mm-60mm |

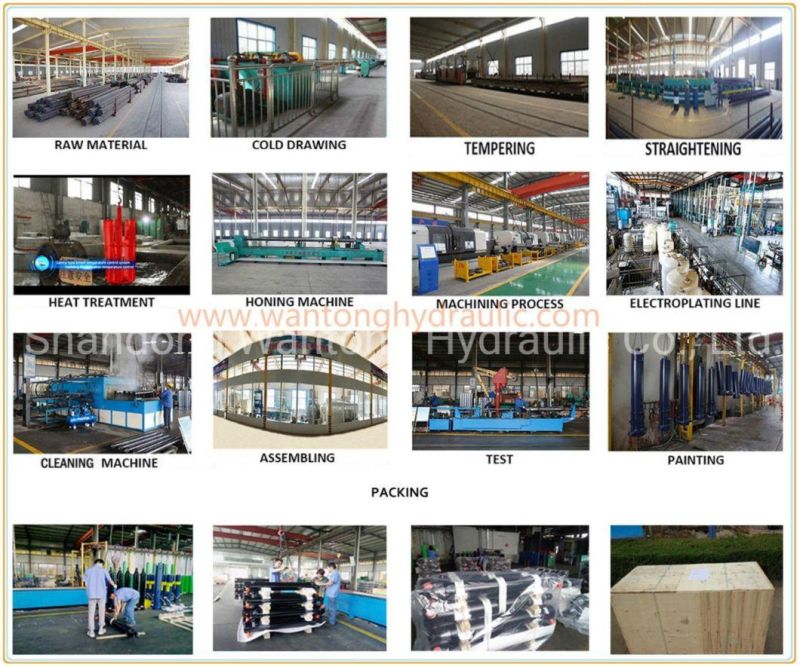

produce line

700 sets manufacturing equipment,such as cold drawing production line ,heat treatment production line ,surface treatment production line,testing equipment,various digital-control machining equipment,gantry style linear electroplating production line

Quality guarantee system

Program before Delivery

1. Trial Operation Test

2. Start-up Pressure Test

3. Pressure-Tight Test

4. Leak Test

5. Full Stroke Test

6. Buffer Test

7. Testing the Effect of Limit

8. Load Efficiency Test

9. Reliability Test

Every piece of hydraulic cylinder are tested and will send out only after they are pasted the each test

Certificates

Guarantee and after sale service:

>7 x 24 hours technical support through email

>Goods will be delivered safely on time

>Warranty within 14 months of the factory date

>Life long time track service

Why Wantong?

1.Complete Manufacturing Processes:

The company has complete and total manufacturing processes from raw material entering to factory and up to the final finished products to customer.Which all are done under same premises.Therefore we can control the quality and delivery time at our best.

2.Strict Quality Control system:

We have gained ISO/TS16949, CCRI, CCS, and DNV AND ABS, API,etc and the quality of the products has been controlled in strict accordance with the certification standard.

3.Rich Market Experiences:

Many years cooperation with famous brands,likeSINOTRUK,CIMC,SHACMAN,ZMJ and YANKUANG GROUP.

FAQ

Q1: Are you a manufacture or a trade company?

Answer: Manufacture, we are the leader manufacturer of hydraulic industry in China with 20 years' experience and technology accumulation. With strong technical team we could solve any annoyance of you.

Q2: Do you have quality control system?

Answer: Yes, The quality management system introduced is: ISO/TS 16949:2009-certified by NQA and IATF cert.

Q3: How can i get a booklet and buy a cylinder from you?

Answer: Very easy! Just leave me a message or email or call me directly, let me know you are interesting in our products. I will talk with you for the details soon!

Q4: Can you tell me the price for the cylinder?

Answer:

1. Please advice the drawing with technical requirement.

2. Please advice the model No. after you check our booklet.

3. Please advice the tipping capacity, number of stages, closed length, mounting type and size.

4. Please also help advice the quantities, this is very important.

Q5: Do your products come with a warranty?

Answer: Yes, we have one year warranty. In this year, if the quality problem we will free repair for you.

Q6: Hydraulic cylinder internal leakage?

A: 3 main reasons causing internal leakage: Overload, polishing bad controlled, cheap seal kits. As is known to all, vehicles in China are often overloaded, our products all designed to bear the overload power. Advanced equipment could assure the polish processing. And we use the imported/TOP brand seals to meet customers' requirement.

Q7: What about the quality feedback of your products?

A: WE HAVE NEVER RECEIVED EVEN ONCE QUALITY COMPLAINT FOR MANY YEARS OF INTERNATIONAL BUSINESS.

Q8: Can you help me to install or recommend what kind of hydraulic cylinder or power pack should I use for specific machine?

Answer: Yes, we have 25 experienced engineers who are always ready to help you. If you do not know what kind of hydraulic cylinders should be used in your machine, please just contact us, our engineers will design the exact products match your need.

Q9: What is the delivery time?

Answer: Within 15 days for samples.

20 days for bulk production, which is depend on quality, production process and so on.

Dream

*Company vision:Act as the laeder of internal hydraulic industry

*Enterprise concept:Better and stronger

*Core values:Learning and innovation,equality and justice,customers the first,and quality winning the world

*Enterprise spirit:Complete sincerity,complete precision more excellent,and up to date

*Quality policy:Pursue zero defects of our products,and realize zeo

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23