Customized Cooking with Stirring Steam Jacketed Cooking Pot for Jam Jacket Kettle

Wuxi Xinrun Protective Film Co., Ltd. / 2022-07-05

- After-sales Service:Video,Door to Door

- Warranty:1 Year

- Customized:Customized

- Certification:CE

- Scale:Medium

- Automation:Automatic

=== Base Info ===

- Model NO.:TSJC-300

- Principle:Hot Water Cooking

- Structure:Double Jacketed

- Operation:Intermittent

- Energy:Heat Sterilization

- Property:Physical Sterilization

- Type:Induction Electronics Sterilization Equipment

- Material:304 Stainless Steel or According to Customer Requi

- Power:0.75kw

- Speed Mode:Automatic

- Voltage:380V,50Hz

- Capacity:300L

- Consumption:110kg,Hr

- Transport Package:According to Customer Requirement

- Specification:According to customer requirement

- Trademark:AMBITIOUS

- Origin:China

- HS Code:8438600000

- Production Capacity:200pieces,Year

=== Description ===

Basic Info.

Model NO. TSJC-300 Principle Hot Water Cooking Structure Double Jacketed Operation Intermittent Energy Heat Sterilization Property Physical Sterilization Type Induction Electronics Sterilization Equipment Material 304 Stainless Steel or According to Customer Requi Power 0.75kw Speed Mode Automatic Voltage 380V/50Hz Capacity 300L Consumption 110kg/Hr Transport Package According to Customer Requirement Specification According to customer requirement Trademark AMBITIOUS Origin China HS Code 8438600000 Production Capacity 200pieces/YearProduct Description

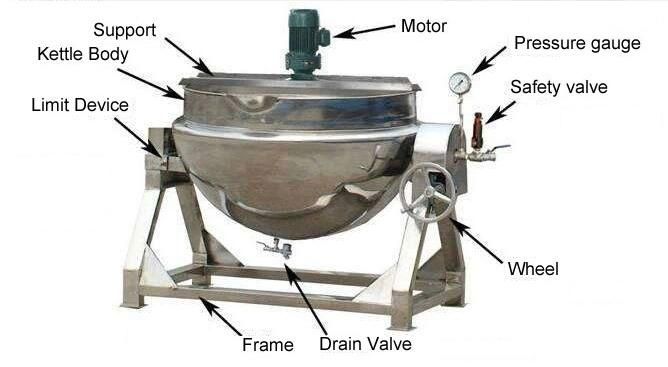

Customized Cooking With Stirring Steam Jacketed Cooking Pot For Jam Jacket Kettle1. -Machine Introduction

Steam jacketed kettle works with the steam from high pressure boiler as its energy, is suitable for canned foods, soup, meat and vegetable processing, has the advantages of aesthetic appearance, durable, safety, energy-saving, and convenient in use, exquisite workmanship, etc.

The jacket structure makes the kettle body heated evenly, high thermal efficiency, the entire structure is designed compact and reasonable, small footprint, high standardization of accessaries, furthermore, also low failure rate and easy maintenance.

Because the steam jacketed kettle uses the a certain pressure steam as its heating source, its own heating area is large, and uniform heating, liquid boiling time is short, the heating temperature is easy to be controlled, and so on.

The kettle is made of the acid and heat resistant stainless steel, and equipped with a pressure gauge and safety valve, this makes itself easy to be operated and more safe.

Steam jaketted kettle is the first choice for the clients who have boilers, the notible feature is save energy, and one set of heavy boiler can be connected with multi-set of kettles which are preferred when the output is asked for more heavy.

Features:

Steam temperature can reach 121 degrees centigrade.

Corollary equipment: With blender, without blender.

Structure: Vertical(or fixed), tilting.

2. -Technical Data

| 1 | Model | TSJC-300 |

| 2 | Heating method | Steam |

| 3 | Temperature | 100 ° C or less |

| 4 | Steam consumption | 110Kg/Hr |

| 5 | Heating area | 1.44m2 |

| 6 | Power | 1.5KW |

| 7 | Agitator | With |

3. -Details

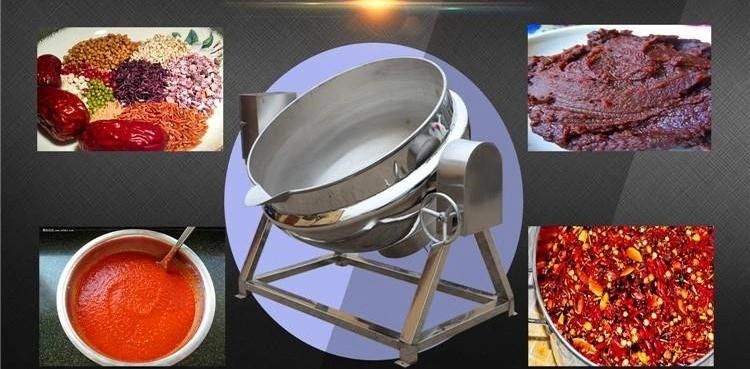

4. -Suitable For Products

Steam heating kettle fits for the customers who have boiler, at the same time, especially who will use multi-set of kettles.

It is widely used in various types of food processing and cooking industry like dairy foods,vegetable,meat,cake,preserved fruit,canned food,candy,sauce products,soup,etc,and also used in processing beverage,wine,pharmacy,daily chemicals as well,is an ideal food equipment to improve food quality,shorten working time,and change the working conditions more better, makes

processing of food,beverage,pharmacy and other products automatic.

5. -Using Scene

6. -Applications

7. -Company Profile

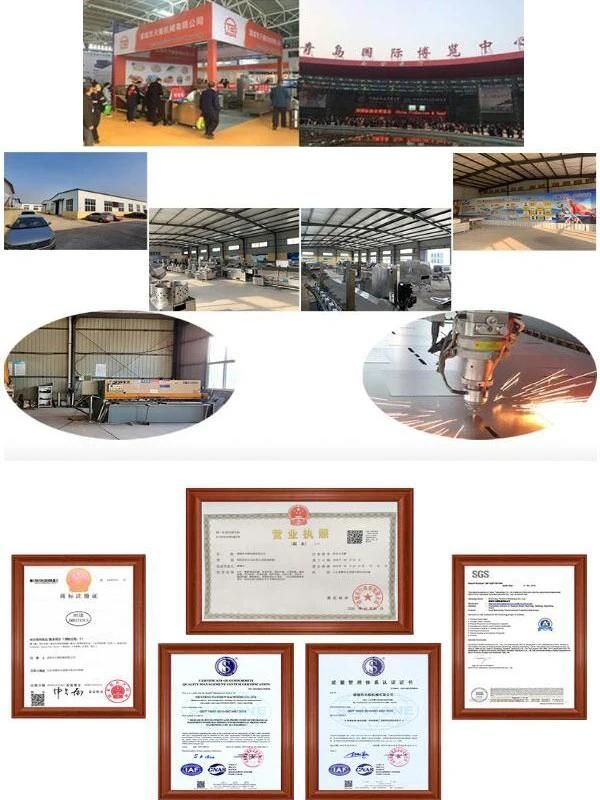

Zhucheng Tianshun Machinery Co.,Ltd. has grown into a large, specialized food machinery manufacturing enterprise which integrates R & D and manufacturing. Currently has more than 100 employees, the division of labor is professionalization and specific, there are technical department, after-sales service department, domestic marketing department, international business department, etc. The company has all kinds of welding equipment, machining equipment to meet the needs of different customers.

Main products: Food machinery and complete production lines, including:

Vegetables&fruits cutting machines,

Peeling&washing machines,

Frying equipment,

Air drying machinery,

Blanching&cooking machine,

Food flavoring machine,

Food coating machine,

Freeze dryer,

Jacketed kettle,

Vacuum packing machine,

Complete production line for vegetables,snack foods,etc.

All of them can be designed semi-automatic and full automatic, and widely used for processing varieties of vegetable, fruits, fish, seafood, etc. Some of them have pass the CE certificate. All of them could be customized, and we also provide and design individual machines for customers.

8. -Our Clients

9. -Packing And Shipment

10.-FAQ

Q1.Could we visit your factory to check the machine carefully and closely?

A:Welcome to our facotry,will provide machines testing service,face-face discussing,turnkey project design solution.

Q2.How long is your machine's guarantee time?

A:1 year without normal wear parts,machine itself life guaranteed.

Q3.If we have very special request for the complete production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q4.If we show you our layout of factory,can you help to design the whole process line?

A:Layout design service provided after received customer's factory layout size.

Q5.If we have samples of new products,can you help to analysis and design the machine?

A:Yes,our technical department can help to analysis,design and test the new products based on the specific requirements you provided.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23